Application of 3D printing technology and quality by design approach for development of age-appropriate pediatric formulation of baclofen

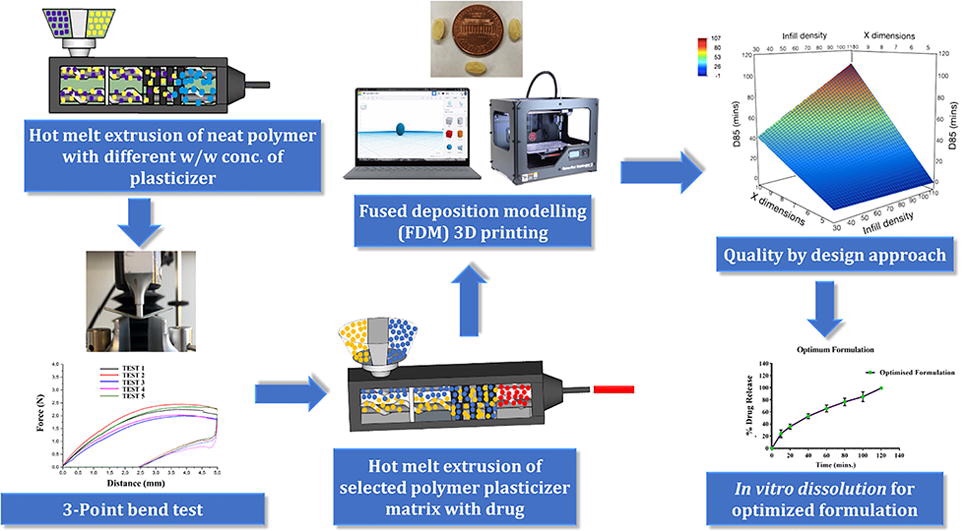

Pediatric population is a sensitive sector of the healthcare and pharmaceutical field with additional needs compared to the adult population. Extemporaneous formulations for children are generally prepared by manipulating adult formulations, but medication errors can result in suboptimal efficacy and with significant safety concerns. The aim of proposed project was to explore a 3D printing technology for the development of customized minicaplets of baclofen for the pediatric population. Based on results of 3-point bend test, polyvinyl alcohol (PVA) with sorbitol (10% w/w) were selected for preparation of baclofen loaded filaments using hot melt extrusion (HME). Effect of dimension, infill percentage and infill pattern on dose, disintegration time and release profile were investigated. Characteristic crystalline peaks of baclofen were absent in DSC thermograms and XRD pattern of filament and minicaplets. Minicaplets printed in diamond (fast) infill pattern with 100 % infill showed higher disintegration time (38 mins) compared to linear, sharkfill and hexagonal pattern. 32 full factorial orthogonal design suggested that baclofen release (D50 and D85) was marginally affected by infill percentage but significantly affected by caplet dimension (p<0.05). Thus, low cost FDM 3D printing technique can be a promising alternative for preparation of dose and release customized pediatric dosage forms.

Continue on 3D printing for Pediatrics

Siddhant Palekar, Pavan Kumar Nukala, Saurabh M. Mishra, Thomas Kipping, Ketan Patel,

Application of 3D printing technology and quality by design approach for development of age-appropriate pediatric formulation of baclofen, International Journal of Pharmaceutics, Volume 556, 2019, Pages 106-116, ISSN 0378-5173, https://doi.org/10.1016/j.ijpharm.2018.11.062.