Solidifying ticagrelor loaded self-microemulsifying drug delivery system

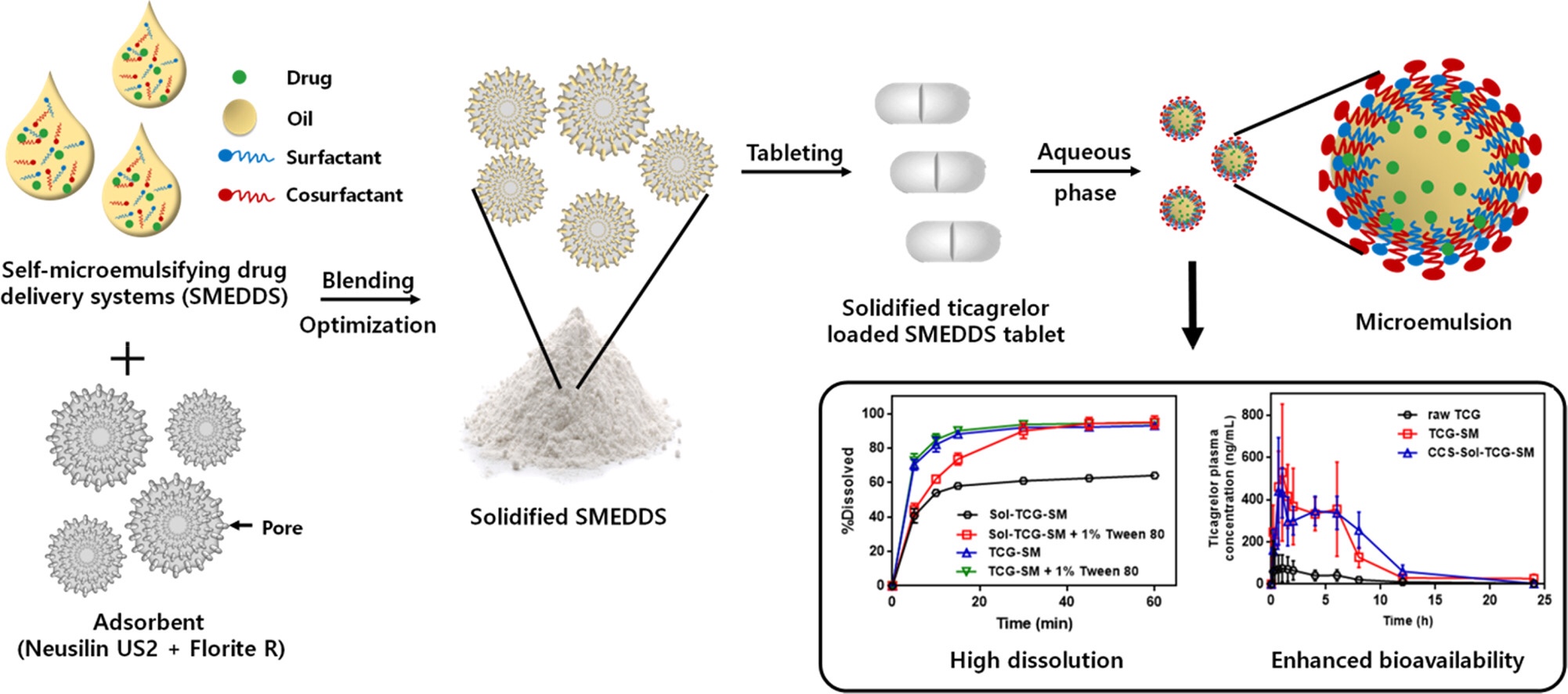

The aim of this study was to solidify a ticagrelor loaded self-microemulsifying drug delivery system (TCG-SM) with enhanced dissolution and bioavailability of ticagrelor (TCG) for developing TCG-SM granules and tablets.

TCG was dissolved in the self-microemulsifying drug delivery system (SMEDDS) and TCG-SM was solidified by adsorption to the optimized adsorbent through statistical design. In order to select an appropriate adsorbent, the physical properties (bulk density, tapped density, angle of repose, and liquid adsorption capacity) of silica-based adsorbents (Neusilin US2, Florite R, Aerosil 200, and Florite PS-10) and non silica-based adsorbents (Avicel PH102, Pharmatose 100M, Pearlitol 200, LH-11, and Emcompress) were investigated.

Neusilin US2 and Florite R were selected as suitable adsorbents and their mixing ratios were optimized using statistical experimental design. The predicted values of physical properties by statistical design showed the error percentage of <10% compared to actual values. As a result of the statistical approach, TCG-SM (490 mg) was successfully solidified with Nesulin US2 (167.8 mg) and Florite R (82.2 mg), which showed good powder properties and improved dissolution of TCG.

The solidified TCG-SM (Sol-TCG-SM), disintegrant (croscarmellose sodium), diluent (microcrystalline cellulose), binder (polyvinylpyrrolidone), and lubricant (magnesium stearate) were mixed to prepare granules. And, the granules with total weight of 900 mg were tableted using 16 mm oval-shape punch. The prepared Sol-TCG-SM tablet showed good tablet properties and maintained self-microemulsifying ability, such as microemulsion formation and enhanced dissolution of TCG.

In vivo pharmacokinetic study, the relative bioavailability of Sol-TCG-SM exhibited 108.1% and 632.7% compared to TCG-SM and raw TCG powder, respectively. In conclusion, we successfully solidified SMEDDS with improved oral bioavailability of insoluble drugs such as TCG through a statistical design. This suggests a new approach that can be utilized in the production of solidified SMEDDS. More on solidified SMEDDS