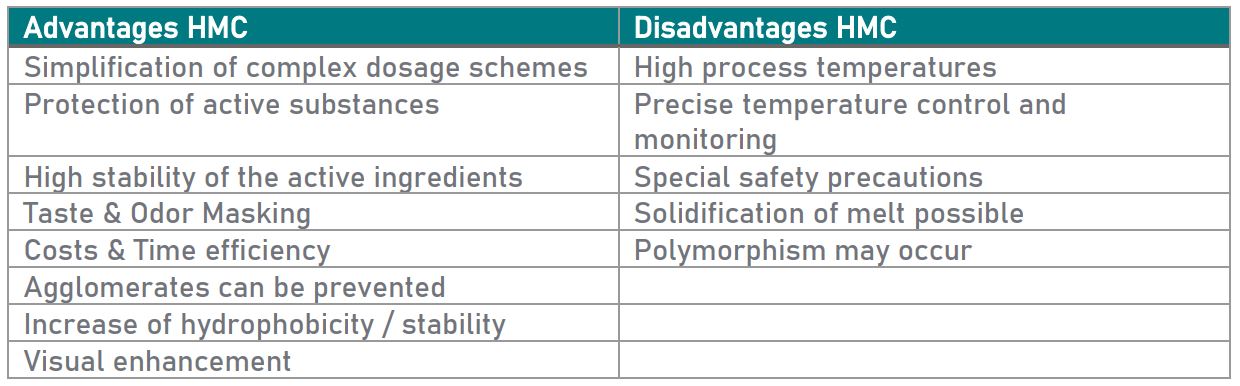

Advantages and disadvantages of Hot Melt Coating

Advantages of Hot Melt Coating (HMC)

One advantage for the pharmaceutical industry is the simplification of complex dosage schemes, as several active ingredients can be combined, even those that cannot normally be combined. As the frequency of administration and complexity for users is reduced, the user-friendliness for patients is significantly improved.

The coating ensures that the active ingredients are protected against chemical degradation and their stability is increased until they are taken. The HMC process can be used flexibly. Direct granulates, hard and soft gelatine capsules or MUPS (Multiple Unit Pellet System) tablets can be coated with the process.

A further advantage is the masking of bitter active ingredients, such as caffeine tablets, and the possibility of a controllable release of active ingredients. There are different ways to coat particles.

By using a Hot Melt Coating the coating process can be significantly shortened.

A comparison of the Hot Melt Coating with a polymer coating can confirm this. The Hot Melt Coating process takes 42 minutes and is therefore almost seven times faster than the process with the polymer solution, which takes 278 minutes. In both processes the weight of the active ingredient is 1000 g, the spray rate is 12 g/min and the use of wax or polymer, 500 g.

Because the wax is a melt, there is no suspension. The polymer, on the other hand, must be dissolved in water or in an organic solvent. In this example the amount of water is 2833 g. This means that more product is needed to coat the active ingredient.

Due to the fact that it is a solvent-free process, costs and time are saved. The lack of drying time and the higher batch throughput increases productivity and reduces costs. For the coated active ingredients this also means no formation of undesirable agglomerates and, due to the lipid coating, an increase in hydrophobicity.

In this way, fluid absorption is counteracted, which in turn increases stability. Like other coating processes, the HMC process can also be used to influence the appearance, taste and smell of the tablets.

Disadvantages of Hot Melt Coating

The disadvantages include high process temperatures, which require special safety precautions, since hot fats and waxes are used. It must also be ensured that all components of the production plant are kept at a constant temperature. These include the pump, the output, the spray can and the product. If the process is not precisely controlled and monitored, unwanted polymorphs can occur. In addition, slight temperature fluctuations lead to solidification of the melt.

Conclusion

More Information on Hotmelt Coating – click on picture to download the brochure

Get a free sample

This is the third article of our small series on Hot Melt Coating