Croda

At Croda International Plc, we offer a vast portfolio of excipient solutions including specialised lipids, high purity speciality chemistries, and key functional ingredients which solve the challenges faced by pharmaceutical manufacturers and formulators.

At Croda International Plc, we offer a vast portfolio of excipient solutions including specialised lipids, high purity speciality chemistries, and key functional ingredients which solve the challenges faced by pharmaceutical manufacturers and formulators.

Our expertise

Established in 1925, Croda is the name behind high performance ingredients and technologies in some of the world’s leading brands. At Croda we are experts in high purity pharmaceutical excipients, high performance vaccine adjuvants, lipid technology custom synthesis, analytical capabilities, and in-house formulation. Croda has decades of experience, making us the ideal solutions provider with whom to navigate your drug and vaccine formulation challenges. Croda can help you succeed by providing quality, regulatory, innovation, and technical expertise to enhance the performance of your API. Discover the Croda difference!

SEE CRODA EXCIPIENTS IN THE SHOP

Our products

Super Refined™ excipients

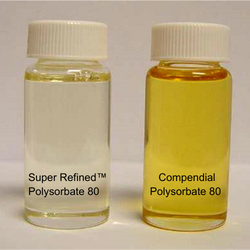

For the needs of very sensitive applications, we’ve developed our Super Refined™ range of excipients, to ensure that your formulations are stable, effective, and consistent.

Offering the most highly purified excipients available, our Super Refined range of excipients are manufactured through proprietary processes that physically remove multiple oxidative impurities such as peroxides, aldehydes, and catalyst residues without affecting the fundamental structure in any way. The removal of these problematic species adds value to the formulated drug product by reducing negative API/excipient interactions and minimising the potential for oxidation, thereby maintaining the stability of the drug and the final formulation, increasing product shelf life.

Most of our products meet the needs of multiple monographs such as the USP/NF, PhEur, JP/JPE, and ChP.

![Crodas Super Refined Colour difference]() View our Super Refined™ range:

View our Super Refined™ range:

Differences between Super Refined & High Purity emulsifiers:

- Colour difference

- Process difference

- Higher purity starting materials (fatty acid & sorbitol)

- Manufactured under milder conditions, preventing caramelization

- Sensitivity

- Residual impurities removed from Super Refined grade

Improving drug stability: Using Super Refined ingredients not only ensures that your drug will remain stable in solution but can also make analysis of the product significantly easier. In the below graph, you can see increased API recovery while using our Super Refined excipients compared to compendial grades implying a higher degree of formulation stability.

Minimising cellular irritation: Our proprietary purification process removes the oxidative impurities found in excipients that cause pain and irritation upon drug application or injection, minimising cellular irritation. In the below graph, you can see that Super Refined Polysorbate 80 displayed a significantly lower irritation potential at all concentrations tested compared to standard pharmaceutical grade Polysorbate 80.

Minimising cellular irritation: Our proprietary purification process removes the oxidative impurities found in excipients that cause pain and irritation upon drug application or injection, minimising cellular irritation. In the below graph, you can see that Super Refined Polysorbate 80 displayed a significantly lower irritation potential at all concentrations tested compared to standard pharmaceutical grade Polysorbate 80.

Reducing taste impact: Super Refined ingredients have a higher Degree of Difference over standard compendial versions, reducing taste impact for the excipient.

Reducing taste impact: Super Refined ingredients have a higher Degree of Difference over standard compendial versions, reducing taste impact for the excipient.  Solubility guide: Croda has determined the solubility of a range of actives in a number of Croda’s high purity excipients. Below you can see a sample taken from our extensive solubility guide available on our website.

Solubility guide: Croda has determined the solubility of a range of actives in a number of Croda’s high purity excipients. Below you can see a sample taken from our extensive solubility guide available on our website.

And beyond…

- Super Refined™ Cottonseed

- Super Refined™ PEG 300

- Super Refined™ P35 Castor Oil

- Super Refined™ Peanut Oil

- Super Refined™ Brij O2

- Super Refined™ Benzyl Alcohol

- Super Refined™ Polysorbate 80

- Super Refined™ PEG 400

- Super Refined™ Sesame Oil

- Super Refined™ Oleic Acid

- Super Refined™ Castor Oil

- Super Refined™ Soybean Oil

Don’t see what you’re looking for? Connect with us! Croda has an extensive product portfolio of different chemistries. If specific chemistries or any other parameters are required, we take pride in working with our customers to help find a tailored solution for your application.

Super Refined™ Polysorbates

Super Refined Polysorbates solubilise and stabilise the most sensitive APIs (active pharmaceutical ingredients) across dosage forms including injectable and oral. At Croda, we offer a range of highly purified polysorbates with multiple compendial monographs for usage across dosage routes.

Our Super Refined Polysorbate range:

- Super Refined™ Polysorbate 80

- Super Refined™ Polysorbate 80 POA

- Super Refined™ Polysorbate 60

- Super Refined™ Polysorbate 20

Super Refined Polysorbate 80 is an extremely mild and effective oil-in-water emulsifier and solubiliser with the following general structure: Batch to batch consistency: The controls in place during the Super Refined manufacturing process ensures that there is limited differences in species distribution across multiple batches. A high level of consistency across multiple batches shows that final formulation performance will not be affected when using Super Refined or High Purity Polysorbate 80.

Batch to batch consistency: The controls in place during the Super Refined manufacturing process ensures that there is limited differences in species distribution across multiple batches. A high level of consistency across multiple batches shows that final formulation performance will not be affected when using Super Refined or High Purity Polysorbate 80.

Lipid Technology

As the Lipid Technology segment of the Croda business, part of the Life Sciences sector of Croda, Avanti is primarily focused on developing innovative lipid-based products of unparalleled purity to address specific medical challenges that are not resolved by current technology or drug products.

As the Lipid Technology segment of the Croda business, part of the Life Sciences sector of Croda, Avanti is primarily focused on developing innovative lipid-based products of unparalleled purity to address specific medical challenges that are not resolved by current technology or drug products.

For over 30 years, Avanti has been working with the pharmaceutical and diagnostic industry to provide solutions that save or improve lives. Over the past decade, we have concentrated on developing the lipid components used in Lipid Nanoparticle (LNP) delivery technology to solve the stability and delivery issues associated with mRNA-based vaccines and therapeutics, as well as gene editing technology. Avanti’s clients include Pharmaceutical Industries, Nutraceutical Industries and Lipid Researchers. People do amazing things with our lipids. What will you do?

Administration routes

Croda’s Super Refined™ excipients provide several benefits across multiple dosage routes. Our extensive experience in highly purified excipients enhance our ability to provide products, solutions, and benefits across dosage routes such as oral, topical, auricular, ophthalmic, nasal, and injectable.

Our product range provides a variety of functions including but not limited to solubilisers, emulsifiers, and emollients.

Researching a particular dosage route? See below to understand the benefits relating to your specific administration route.

![Oral Drug Delivery]() Oral drug delivery

Oral drug delivery

Benefits:

- Increasing stability of the drug

- Improving stability in gelatin capsules

- Less impact of taste, odour, and colour

Related Literature:

![Topical Drug Delivery]() Topical drug delivery

Topical drug delivery

Benefits:

- Increasing skin penetration enhancers

- Decreasing cellular irritation to improve patient compliance

- Reducing oxidation potential

Related Literature:

![Auricular, ophthalmic, and nasal]() Auricular, ophthalmic, and nasal

Auricular, ophthalmic, and nasal

Benefits:

- Reducing peroxide values

- Reducing cellular irritation

- Reducing endotoxin levels

Related Literature:

![Injectable Drug Delivery]() Injectable drug delivery

Injectable drug delivery

Benefits:

- Reducing API costs

- Improving product safety profiles

- Lengthening product shelf lives

- Improving patient comfort

Related Literature:

- Super Refined Parenteral

- Maximise the Performance of Your APIs

Virodex™ excipients

The Virodex™ range offers two products, TXR-1, and TXR-2. Both products have been shown to have equivalent or better performance in virus inactivation and cell lysis applications than Triton™ X-100 and three other marketed products available today. The Virodex™ products are non-denaturing detergents that show excellent protein compatibility and high batch-to-batch consistency. These qualities make Virodex™ TXR-1 or TXR-2 excellent options to consider incorporating into your existing or new biomanufacturing processes.

Benefits:

- Sustainable and REACH-compliant

- Meets cGMP EXCiPACT standards for the highest product quality in biopharmaceutical manufacturing

- Known use of chemistry by industry for viral inactivation

- No risk of nitrosamine formation

- Improved biologic quality and lower biomanufacturing risk, enabling faster speed to market

- Equivalent virus inactivation and cell lysis characterization to Triton™ X-100, with better performance than three market alternatives

- Comes with additional COA testing: bacterial endotoxin, Total Aerobic Microbial Count (TAMC), and Total Yeast and Mould Count (TYMC)

Virodex™ excipients:

Brochures

![Croda Website Registration]() Website registration

Website registration

For further brochures and information, please visit our website registration page. Our online platform offers you all the necessary product information, literature, and technical support you need for your development.

Croda’s commitment to quality

Croda understands the importance of excipient quality in pharmaceutical development. All our excipients are designed and manufactured for pharmaceutical use, using Good Manufacturing Practice (GMP) standards, from start to finish, across all our platforms and manufacturing sites. We were one of the first excipient suppliers to receive EXCiPACT (or equivalent) certifications across all our global sites and we continue to pioneer new monograph approvals via our representation on global monograph industry forums. We believe that having the highest quality and purest grades of excipients helps our customers formulate seamlessly and drive products to market quickly and efficiently.

Global manufacturing capabilities

Looking globally? Wherever you are, we are here to provide you with the solutions you are looking for.

Mill Hall / USA:

- EXCiPACT GMP certified

- ISO 9001:2015 – Quality Management System

Leek / UK:

- MHRA approved for the manufacture of API to EU GMP (ICHQ7)

- FDA inspected for the manufacture of API to USA GMP

- KFDA inspected for the manufacture of API to Korea

- EXCiPACT GMP certified

- ISO 9001:2015 – Quality Management System

Shiga / Japan:

- EXCiPACT GMP certified

- ISO 9001:2015 – Quality Management System

Croda and our Commitment to Sustainability

Through our Commitment to science-based targets and the United Nations Sustainable Development Goals (SDGs), we will be the most sustainable supplier of innovative ingredients. We will create, make and sell solutions to tackle some of the biggest challenges the world is facing.

Croda’s 2030 Commitment will make us the most sustainable supplier of innovative ingredients, with our action plan for the decade is to be Climate, Land and People Positive by 2030.

Croda’s Commitment in action can be seen through our 2030 Commitments and accomplishments such as the 2021 Sustainability Leadership Award granted to Avanti Polar Lipids recognising the ‘societal contribution’ to the development and deployment of the Pfizer-BioNTech COVID-19 vaccine.

Croda’s Purpose – Smart science to improve lives™ – underpins our Commitment to sustainability. Smart science embodies our innovative philosophy and ability to offer customers something different and valuable. Improving lives describes the positive impact Croda’s products have in use and how we are working to reduce the environmental impact of our actions.

Contact Croda International Plc

Connect with our dedicated teams within your region!