Excipients in freeze-dried biopharmaceuticals: Contributions toward formulation stability and lyophilisation cycle optimisation

Biopharmaceuticals are one of the fastest growing areas within the pharmaceutical industry.

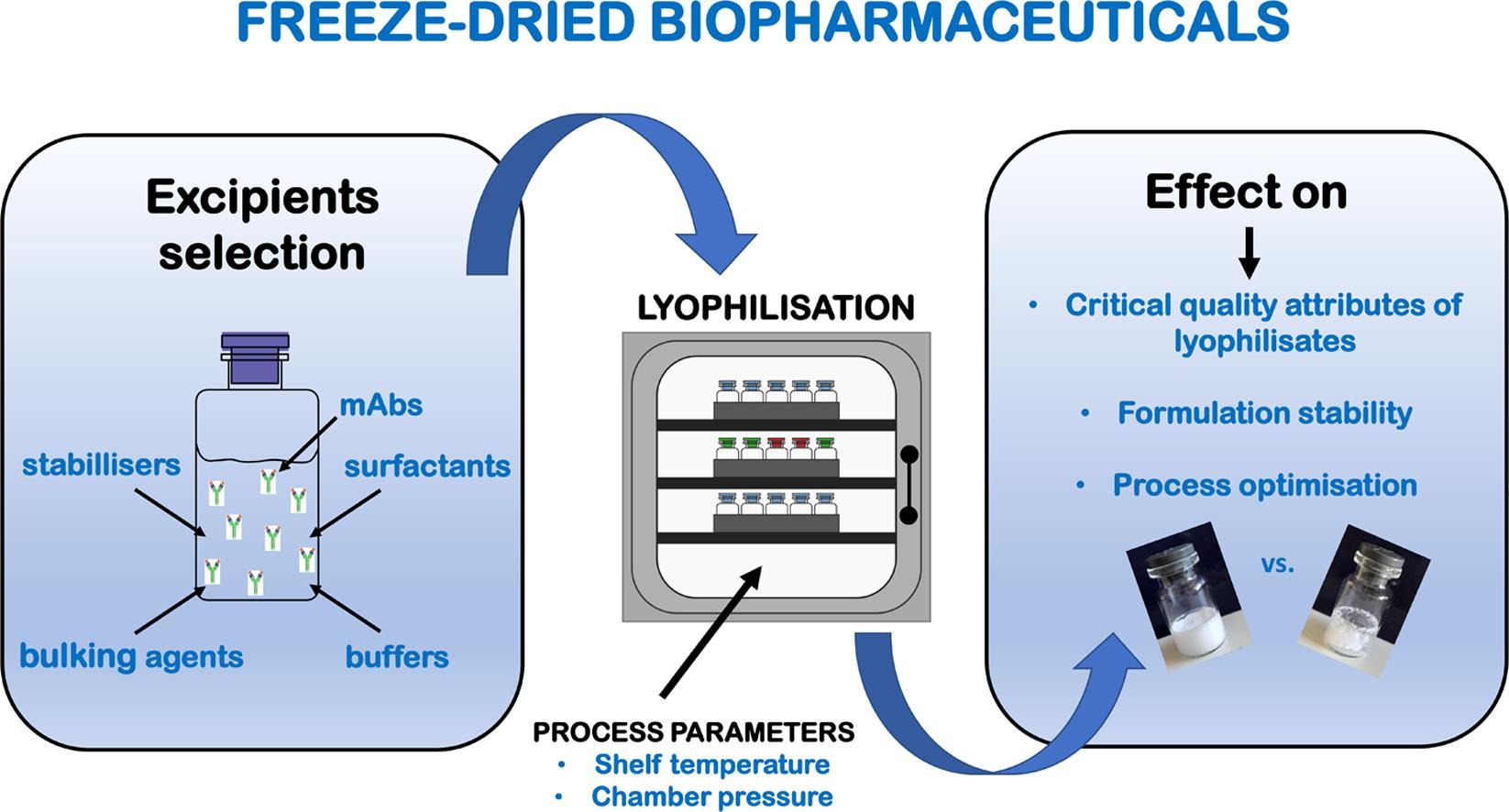

As protein drugs require parenteral administration, they are commonly formulated as aqueous solutions. However, this is not always feasible due to their general instability. In such cases, lyophilised powders for injection are the dosage form of choice, for the preparation of stable products. Lyophilisation is known to be highly time and energy consuming, and hence it is an expensive technological process.

Thus, the pharmaceutical industry is increasingly focused on its optimisation. Implementation of aggressive conditions, together with optimisation of formulation parameters, represent the contemporary approach to reduction of the primary drying time. As such, incorporation of drug-specific excipients can contribute significantly to the stability of a biologically active ingredient, and indirectly they can also affect the time needed for lyophilisation.

The addition of the most relevant protein stabilisers, surfactants, buffers and bulking agents is therefore crucial. The main aim of the present review is to define the most important groups of biopharmaceutical excipients, based on their roles in formulations and the mechanism(s) through which they support the lyophilisation process, to provide products with the required protein efficiency and product characteristics.

The scope of the article is to critically discuss the suitability of novel stabilizers, with higher critical temperatures and bulking agents in terms of implementation of aggressive primary drying. For better assignment of the topic-related challenges, the stabilities of biopharmaceutical drugs and the fundamentals of the lyophilisation process are also briefly described. More on excipients in freeze-dried biopharmaceuticals