Corona alternating current electrospinning: A combined approach for increasing the productivity of electrospinning

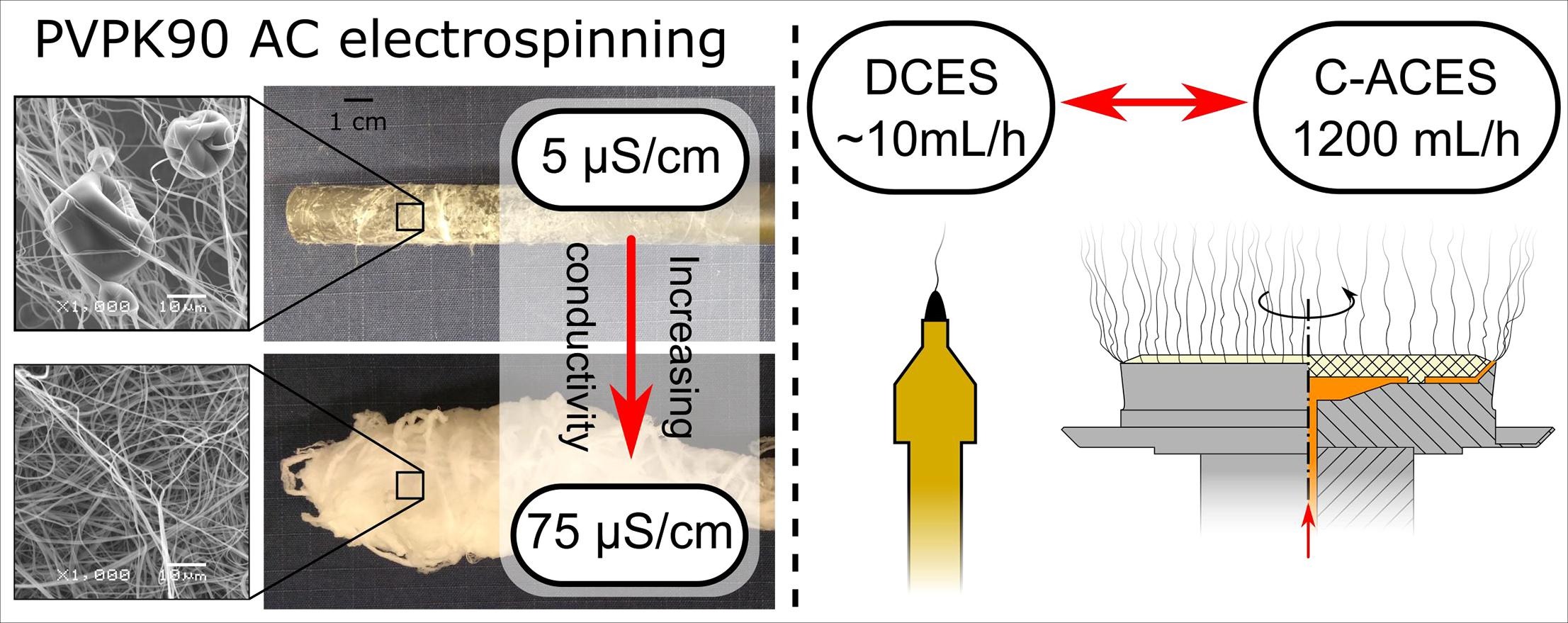

Corona alternating current electrospinning (C-ACES), a scaled-up productivity electrospinning method was developed by combining the intense forces of the alternating electrostatic field and a sharp-edged spinneret design with increased free surface. C-ACES reached two orders of magnitude higher productivity (up to 1200 mL/h) than the classical single needle direct current electrospinning (DCES) without any alteration of fiber properties.

Polyvinylpyrrolidone K90 (PVPK90), a water soluble high molecular weight nonionic polymer was processed for the first time with single needle alternating current electrospinning (ACES) and C-ACES in order to prepare fast dissolving amorphous solid dispersions of spironolactone (SPIR), a poorly water-soluble antihypertensive model drug. The limited spinnability of PVPK90 with AC high voltage could only be resolved by optimizing the solution conductivity with organophilic salts such as sodium dodecyl sulfate (SDS) demonstrating the importance of conductivity during ACES.

The effects of varied solution properties (composition and conductivity) and scaling-up were investigated by SEM imaging. Solid state analyses revealed that SPIR was dispersed in an amorphous form in the fibrous mats. In vitro dissolution tests showed ultrafast drug release in case of the amorphous formulations even when prepared with scaled-up C-ACES. Besides the enhancement of conductivity SDS also prevents SPIR from precipitation from the dissolution media due to its solubilization ability.

More on electrospinning