Additional information

| Manufacturer |

Meggle |

|---|---|

| Quality |

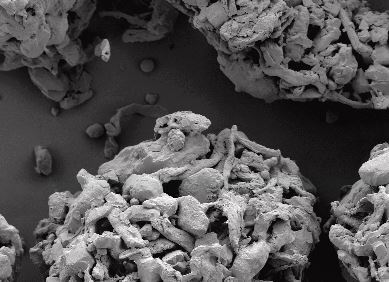

Compound of Lactose Monohydrate USP/NF, EP, JP, JP and Powdered Cellulose USP/NF |

| Composition |

Compound of Lactose & Powdered Cellulose |

| Dosage Form |

Capsules;, Tablets |

| Function |

Direct compression, dry granulation and capsule filling. Suitable for use in low as well as high dose formulations. Also, used as cores for coating |