Lubricants in Pharmaceutical Solid Dosage Forms

| Water soluble lubricant | Amount in formulation (%) | Water insoluble lubricant | Amount in formulation (%) |

|---|---|---|---|

| Boric acid | 1 | Metal (Mg, Ca, Na) stearate | 0.25–2 |

| Carbowax (PEG) 4000/6000 | 1–5 | Stearic acid | 0.25–2 |

| Sodium oleate | 5 | Sterotex | 0.25–1 |

| Sodium benzoate | 5 | Talc | 1–5 |

| Sodium acetate | 5 | Waxes | 1–5 |

| Sodium lauryl sulfate | 1–5 | Stear-O-Wet | 1–5 |

| Mg-Lauryl sulfate | 1–2 | Glyceryl behenate (Compritol 888) | 0.5–3 |

Conclusions

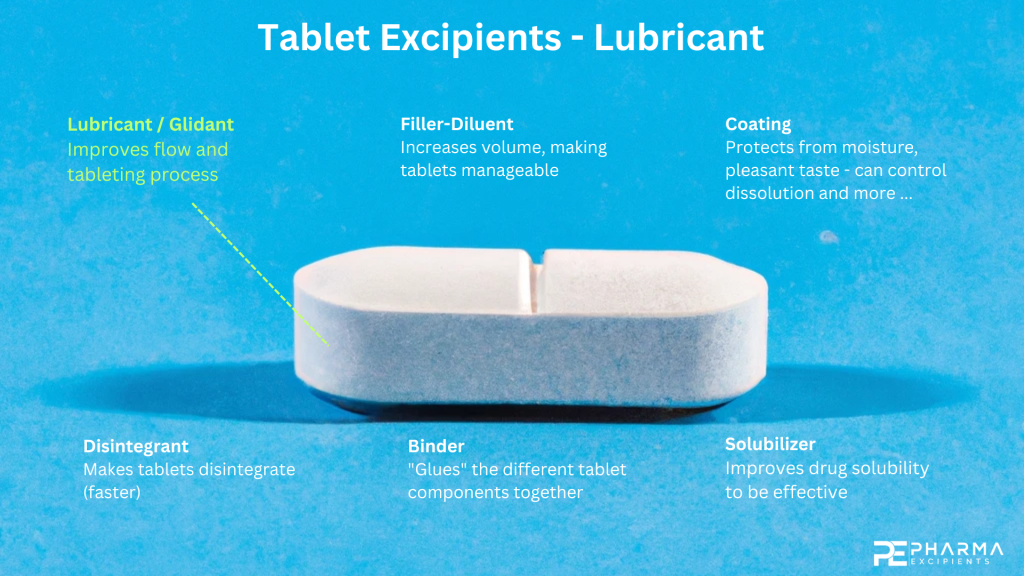

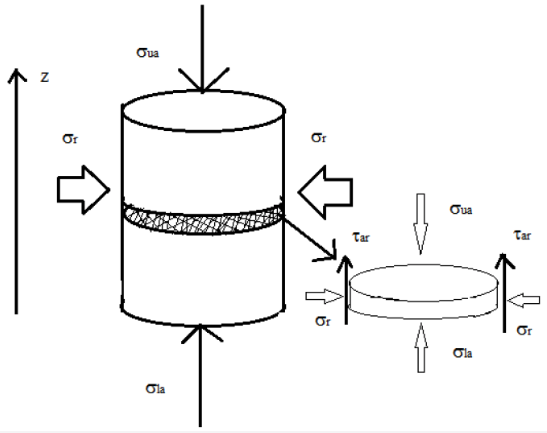

In this paper, the fundamentals of lubrication and the action mechanisms of lubricants in typical pharmaceutical manufacturing processes have been reviewed; the role of lubricants in improving pharmaceutical operations by reducing the adhesion forces between powder/equipment as well as particle/particle in terms of wall friction and inter-particle friction has been summarized. In addition to other classes of lubricants used in the pharmaceutical industry, magnesium stearate as the most frequently used lubricant has been discussed in detail. Furthermore, the lubrication efficacy of hydrates of magnesium stearate and their effect on the performance of formulations in pharmaceutical operations were discussed. Overall, it was concluded that the dihydrate of magnesium stearate is the best hydration state for lubrication. In terms of the effect of lubricant particle size, magnesium stearate with a large surface area and small particle size has the best lubrication efficiency, but it reduced the hardness of tablets and caused slow-down of dissolution. Moreover, the lubricant significantly affects the dynamic process of compaction/compression and the mechanical properties (solid fraction and tensile strength) of ribbons as well as tablets due to the improved flowability of the lubricated blends. For adequate lubrication, on-line monitoring can help to determine the end-point of a blending process, and the distribution of lubricant as well as its composition. Finally, magnesium stearate and its impurities often cause chemical instability of APIs. In selection of a lubricant for a formulation many factors including chemical instability, physical incompatibility, and lubrication efficiency should be considered.

Continue reading the full article: Li, J.; Wu, Y. Lubricants in Pharmaceutical Solid Dosage Forms. Lubricants 2014, 2, 21-43. https://doi.org/10.3390/lubricants2010021