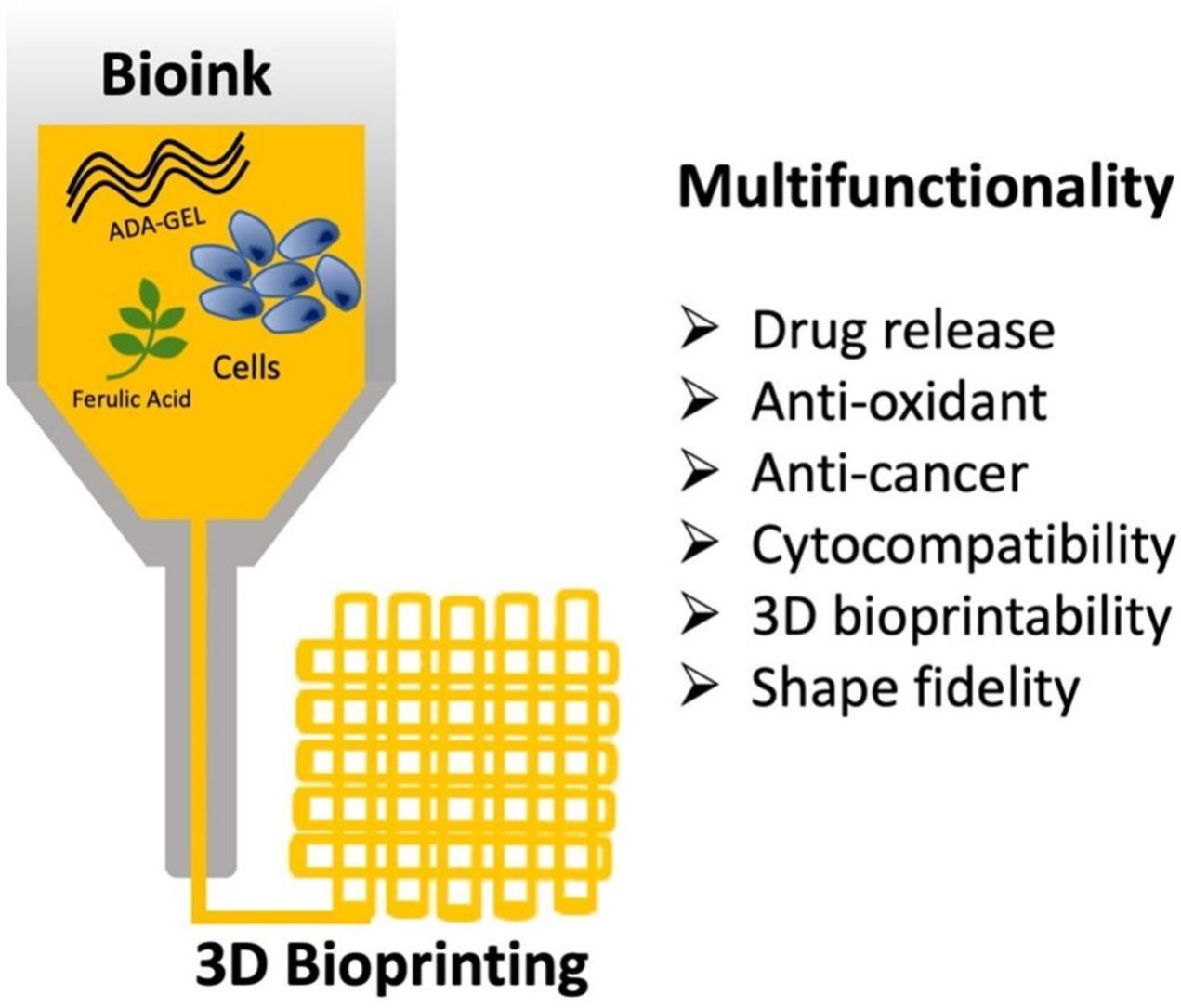

3D bioprinting of multifunctional alginate dialdehyde (ADA)–gelatin (GEL) (ADA-GEL) hydrogels incorporating ferulic acid

The present work explores the 3D extrusion printing of ferulic acid (FA)-containing alginate dialdehyde (ADA)–gelatin (GEL) scaffolds with a wide spectrum of biophysical and pharmacological properties. The tailored addition of FA (≤0.2 %) increases the crosslinking between FA and GEL in the presence of calcium chloride (CaCl2) and microbial transglutaminase, as confirmed using trinitrobenzenesulfonic acid (TNBS) assay. In agreement with an increase in crosslinking density, a higher viscosity of ADA-GEL with FA incorporation was achieved, leading to better printability. Importantly, FA release, enzymatic degradation and swelling were progressively reduced with an increase in FA loading to ADA-GEL, over 28 days. Similar positive impact on antibacterial properties with S. epidermidis strains as well as antioxidant properties were recorded. Intriguingly, FA incorporated ADA-GEL supported murine pre-osteoblast proliferation with reduced osteosarcoma cell proliferation over 7 days in culture, implicating potential anticancer property. Most importantly, FA-incorporated and cell-encapsulated ADA-GEL can be extrusion printed to shape fidelity-compliant multilayer scaffolds, which also support pre-osteoblast cells over 7 days in culture. Taken together, the present study unequivocally establishes the significant potential of 3D bioprinting of ADA-GEL-FA ink to obtain structurally stable scaffolds with a broad spectrum of biophysical and therapeutically significant properties, for bone tissue engineering applications.

Introduction

Tissue engineering (TE) aims to develop biological substitutes to restore and to maintain the functionality of injured tissues/organs [1]. In addition to cells and biological cues (e.g., growth factors), TE requires a scaffold or temporary extracellular matrix based on engineered biomaterials (natural or synthetic). Sodium alginate is a natural hydrogel derived from brown algae and is also used for biomedical applications, such as microencapsulation and 3D printing of scaffolds. The polymer chains of alginate are composed of saccharide blocks (1,4)-linked β-D-mannuronic (M) and α-L-guluronic acid (G) residues. The G blocks might crosslink to divalent cations, such as Ca2+ or Sr2+, to form hydrogels [2]. The crosslinking of alginate-based hydrogels especially, with Ca2+-ions (calcium chloride, CaCl2) is an established approach in 3D printing and drug delivery community [3,4]. Moreover, alginate hydrogels are well known for their biocompatibility, low cost and availability [5,6]. However, high molecular weight of alginate leads to a relative slow degradation rate. To overcome such drawbacks, the oxidized form of alginate, alginate dialdehyde (ADA), is frequently used [7]. Due to the oxidation process, the molecular weight is decreased, which results in a faster degradation rate in comparison to alginate. Moreover, free aldehyde groups form during the oxidation process, which enable the bonding to NH2-groups in protein molecules by Schiff’s base formation [5,8]. Gelatin (GEL) is a bioresorbable and biocompatible hydrogel, which is composed of aspartic acid (RGD) sequences. GEL is reported to improve cell attachment and cell-cell interaction [9]. Microbial transglutaminase (mTG) is an enzyme in human body and has the ability to support blood coagulation and to stabilize protein structures [10,11]. mTG facilitates the crosslinking within the structural proteins by forming bonds between the NH2-groups of glutamine and lysine in collagen and is therefore used as a crosslinker for GEL [10,12].

The formation of biofilms due to bacteria attachment on the surface of biomaterials upon implantation often causes major clinical complications. Biofilm formation might lead to serious infection, resulting in compromised implant function and/or leading to revision surgery in the worst cases [13]. Moreover, biofilm formation might lead to an increasing resistance against antibiotics [14]. In order to avoid the risk of infections, the incorporation/addition of herbal drugs into engineered biomaterials has attracted wider attention, recently due to their biological functionalities [15]. Especially, the addition of phenolic rings containing compounds, such as ferulic acid (FA) [16] or Syzygium cumini seeds [3,4], appears as a promising approach. Ferulic acid (4-hydroxy-3-methoxycinnamic acid) is a plant based compound found in leaves, seeds and in plant cell walls and has the ability to covalently crosslink to protein groups, like lysine, which are present in GEL [17,18]. FA is well known for its antioxidant, antidiabetic, antiaging, anticancer and antibacterial properties [16].

It is worthwhile to mention that FA is considered to exhibit a wide-spectrum of pharmacological properties, including a positive impact on neuroinflammatory and neurodegenerative process [19]. While exploiting many positive attributes of FA, a number of studies investigated the controlled drug release and sustained antioxidant properties of FA incorporated poly(anhydride-ester) [20] and puerarin-FA-polydopamine incorporated polyethylene-glycol-diacrylate (PEG-DA) hydrogel for skin regeneration in wound healing applications [21]. FA has been incorporated into chitosan-based hydrogels for wound healing applications [22], including chitosan-gelatin-glycerol phosphate hydrogels for nucleus pulposus regeneration [23]. Although FA has shown some promise in tissue engineering, particularly for skin regeneration or skin care formulations, the use of FA-incorporated hydrogels based multifunctional scaffolds have not been widely explored.

To the best of our knowledge, Anjali et al. [24] first reported the incorporation of ferulic acid into a self-crosslinking ADA-GEL system as antimicrobial compound for exudating wounds [24]. This study was focused on evaluating the antimicrobial and cell fate evaluation (collagen deposition and cell migration) using human dermal fibroblasts, in establishing the potential for the treatment of moderately exudating wounds. In contrast to this only study on this biomaterial system, the novelty of the present work stems from the usage of enzymatic and ionic crosslinkers, which contributes to the improvement in shape fidelity during 3D bioprinting. Additionally, we evaluate the spectrum of pharmacologically-relevant properties including antioxidant behavior and exploit 3D bioprinting as a novel scaffold production method for FA containing alginate based bioinks. Importantly, good cell viability of bone cells, when printed with the bioink is reported in the present work and all these results thereby present a step forward towards the targeted bone tissue engineering applications.

Against the above backdrop, we used 3 different FA concentrations in ADA-GEL hydrogel to investigate the impact of FA addition on degradation/swelling behavior and mechanical properties. Moreover, the release of FA from 3D printed ADA-GEL scaffolds was investigated. Furthermore, the impact of FA containing ADA-GEL hydrogel on antibacterial properties was investigated. Additionally, an estimation of total phenolic content was made using Folin & Ciocalteu’s phenol reagent and the determination of antioxidant properties was pursued. The In vitro cytocompatibility studies were performed with ADA-GEL-FA hydrogels in terms of a direct cell viability study with MG-63 osteosarcoma cells and MC3TC-E1 (pre-osteoblast) cell lines in order to assess the effect of FA content (≤ 0.2 %). All in all, this study establishes the role of FA as active herbal compound in hydrogels for biomedical applications. The approach to ADA-GEL-FA hydrogels formation and synthesis steps are represented in Fig. 1 a).

Materials

High purity, commercial (pharmaceutical grade) alginate acid powder (sodium salt from marine brown algae, Vivapharm, Germany), gelatin from porcine skin (GEL, Type A, gel strength 300 bloom), sodium (meta)periodate (NaIO4), calcium chloride dehydrate (CaCl2), ethylenglycol and trans-ferulic acid (trans-4-Hydroxy-3-methoxycinnamic acid, 99 %) were purchased from Sigma Aldrich. Dulbecco’s Phosphate Buffered Saline (DPBS, [−] Ca2+, [−] Mg2+), Phosphate buffer saline (PBS, Gibco), Hank’s Balanced

Read more

Faina Bider, Marta Miola, Corina-Elena Clejanu, Johanna Götzelmann, Sonja Kuth, Enrica Vernè, Bikramjit Basu, Aldo R. Boccaccini, 3D bioprinting of multifunctional alginate dialdehyde (ADA)–gelatin (GEL) (ADA-GEL) hydrogels incorporating ferulic acid, International Journal of Biological Macromolecules, 2023, 128449, ISSN 0141-8130,

https://doi.org/10.1016/j.ijbiomac.2023.128449.

Read more on Alginates as Pharmaceutical Excipient here: