Effect of drug load on the aerosolisation propensity of binary adhesive mixtures for inhalation

Abstract

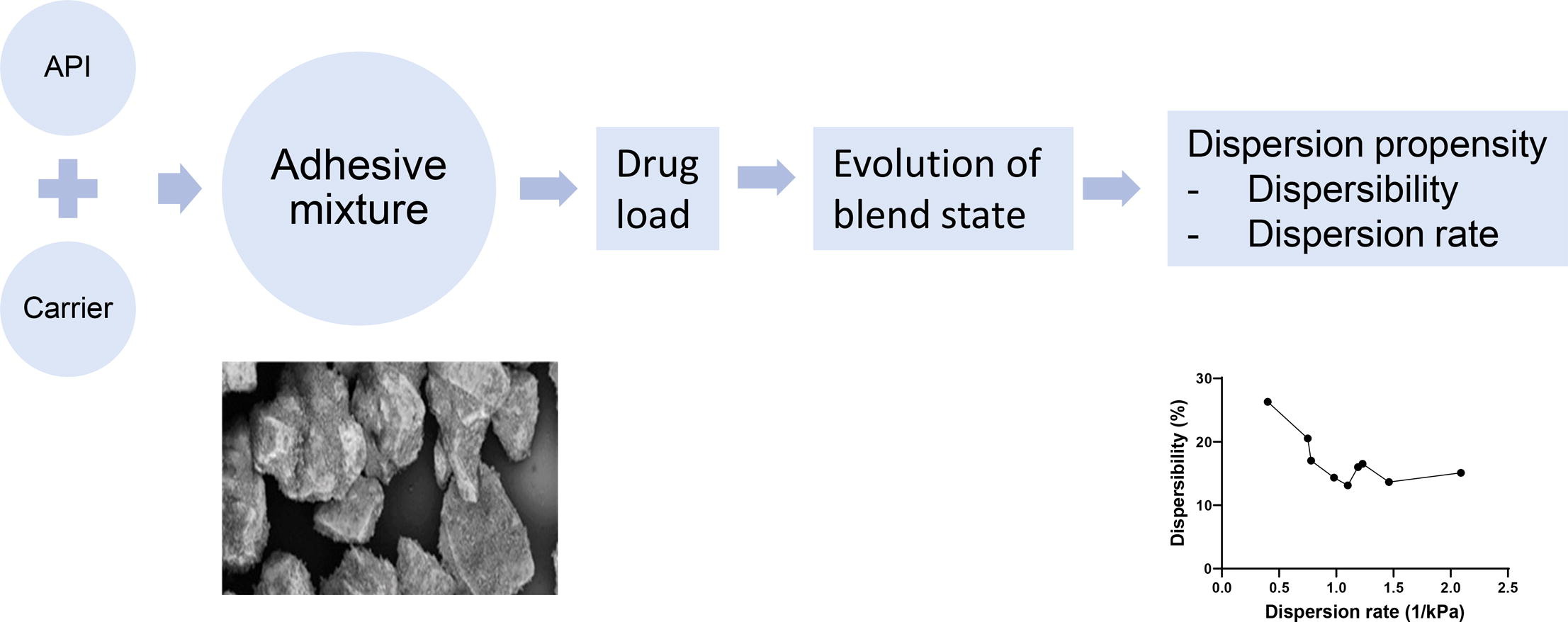

The aim of this study was to investigate how the propensity for aerosolisation in binary adhesive mixtures was affected by the drug load, and to determine whether these findings could be linked to different blend states. Binary blends of two different lactose carriers, each with varying size and morphology, were prepared together with budesonide. In vitro aerosolisation studies were conducted at four different pressure drops, ranging from 0.5 to 4 kPa, utilising a Next Generation Impactor. Several dispersion parameters were derived from the relationship between the quantity of dispersed API and the pressure drop. The evolution of the parameters with drug load was complex, especially at low drug loads. While similar responses were observed for both carriers, the range of drug load that could be used varied significantly. The choice of carrier not only influenced the capacity for drug loading but also affected the spatial distribution of the API within the mixture, which, in turn, affected its aerosolisation propensity. Thus, the drug dispersion process could be linked to different configurations of the lactose carrier and budesonide in the blends, i.e. blend states. In conclusion, the study suggests that the concept of blend states can provide an explanation for the complex dispersion process observed in adhesive blends.

Table 1. Some particle properties of budesonide and carriers (Inhalac 70 and Inhalac 230). Reported values are the mean, with standard deviations within brackets, from three separate measurements of the respective property.

| Material | Apparent particle density (gcm−3) | Particle weight specific surface area (cm2g−1) | Median particle diameter (μm) | Span of particle diameter distribution (−) |

|---|---|---|---|---|

| Budesonide | 1.27 | 45 530 (845) | 2.1 (0.0) | 1.58 |

| Inhalac 70 | 1.54 | 280 (4.00) | 247 (7.0) | 0.74 |

| Inhalac 230 | 1.54 | 661 (11.0) | 104 (0.4) | 1.00 |

Introduction

A common dosage form for pulmonary delivery is the inhalation powder (Mehta, 2018) which generally fall into two categories: carrier-based adhesive blends or carrier-free powders (soft agglomerates and non-cohesive powders). Carrier-based mixtures typically comprise lactose carrier particles to which micronised particles of an active pharmaceutical ingredient (API) adhere. A single carrier particle together with a layer of adsorbed API particles (the adhesion layer) is hereinafter referred to as an adhesion unit. An adhesive mixture consists of a collection of adhesion units, together with a population of free API fines, i.e. API particles that are not attached to a carrier particle. During inhalation, the API particles are supposed to detach from the carrier particles, a process that depends on a variety of factors, including the adhesive and cohesive bindings within the mixture, particle size, surface morphology and the type of inhalation device used (Grasmeijer et al., 2015, Jones and Buckton, 2016, Nguyen et al., 2018, Rudén et al., 2018., Zellnitz et al., 2019, Yeung et al., 2019, Farizhandi et al., 2019).

One limitation in the use of adhesive mixtures is the upper dose limit for a single inhaler actuation, due to the need for a substantial volume of carrier particles in the powder. Historically, doses of API used in inhalation powders were in the microgram range, typically 6–500 μg (Sibum et al., 2018), with a drug-to-carrier mass ratio of 1:67.5 (1.5 %) described as a suitable target drug concentration. However, new medication possibilities have created a need for adhesive mixtures with considerably higher drug loads. Yeung et al. (2018) reported a variation in drug content for 12 carrier-based inhalation powders, varying from 12 μg to 5 mg. The latter had a drug-to-carrier ratio corresponding to 20 % w/w of the drug.

The definition of a high dose and, hence, the boundary line between low and high doses of drugs administered by inhalation is not clearly defined in the literature. Sibum et al. (2018) proposed that doses up to 2.5 mg are considered low doses, while doses above 2.5 mg are viewed as high doses. This distinction between low and high doses stems from two key assumptions: First, that 2.5 mg represents an approximate upper dose limit for which an adhesive mixture can be used in an inhalation powder and second, that a practical maximum for drug concentration in an adhesive mixture is 10 % (with a drug-to-carrier ratio of 1:9). Thus, although adhesive mixtures are, in practice, restricted to low and intermediate doses, the range of drug load can vary significantly, and consequently also the drug concentration (drug load) in the mixture.

The drug concentration in an adhesive mixture, in combination with the particle and surface properties of both the drug and the carrier, will affect the spatial distribution of the drug particles within the blend. Accordingly, efforts to generalise the structural changes that an adhesive blend undergoes with an increased amount of drug fines in terms of consecutive series of stages have been presented in the literature (Young et al., 2011, Rudén et al., 2018 and 2019). Moreover, it is proposed that the structure of the mixture (Young et al., 2011) or its blend state (Rudén et al., 2021) determines the extent to which drug particles disperse as inhalable particles during actuation of a dry powder inhaler (DPI). Thus, the concept of blend state may be useful in providing an understanding of the variables that impact the aerosolisation propensity of adhesive mixtures, warranting further investigation.

The aim of this study was to investigate the relationship between drug load, blend state and the aerosolisation propensity of a series of adhesive mixtures. We specifically ask if the drug load dependent variation in aerosolisation propensity could be linked to the blend state of the mixtures, i.e. if the underlying cause for the variation in aerosolisation propensity is a change in the localisation of attached drug particles and the microstructure of the adhesive layer. To do so, a series of binary adhesive mixtures containing different drug (budesonide) loads were prepared, using two lactose carriers of different size and morphology.

Download the full article as PDF here: Effect of drug load on the aerosolisation propensity of binary adhesive mixtures for inhalation

or read it here

Materials

Micronised Budesonide was provided by AstraZeneca Gothenburg (Sweden) and used as the active pharmaceutical ingredient (API). Inhalac 70 and Inhalac 230 were provided by Meggle (Germany) and used as carriers. Particle characteristics of these powders are presented in Table 1. Furthermore, Tween 80 (Merck KGaA, France) was used as the wetting agent.

LC grade methanol and acetonitrile (VWR International, Fontenay-sous-Bois, France) were used for the UPLC analysis, together with MiliQ water (produced using Purelab Flex ELGA, LabWater, United Kingdom). Fluocinolone acetonide, used as an internal standard (Sigma Aldrich, USA), was diluted in Ethanol (Solveco, Sweden). The phosphate buffer was prepared from sodium dihydrogen phosphate and orthophosphoric acid (both from Sigma Aldrich, Switzerland), as well as MilliQ water. Additionally, the NGI coating agents (Brij 35 and glycerol) were acquired from Sigma Aldrich (Ontario, Canada and Germany, respectively).

Anna Simonsson, Tobias Bramer, Alex Wimbush, Göran Alderborn, Effect of drug load on the aerosolisation propensity of binary adhesive mixtures for inhalation, International Journal of Pharmaceutics, 2024, 124122, ISSN 0378-5173, https://doi.org/10.1016/j.ijpharm.2024.124122.

See our next webinar:

“Rethinking the development of controlled release formulations and manufacturing processes”

Date: 30th of April, Time: 3:00 pm (Amsterdam, Berlin)