Real-time monitoring of multi-layered film coating processes using Raman spectroscopy

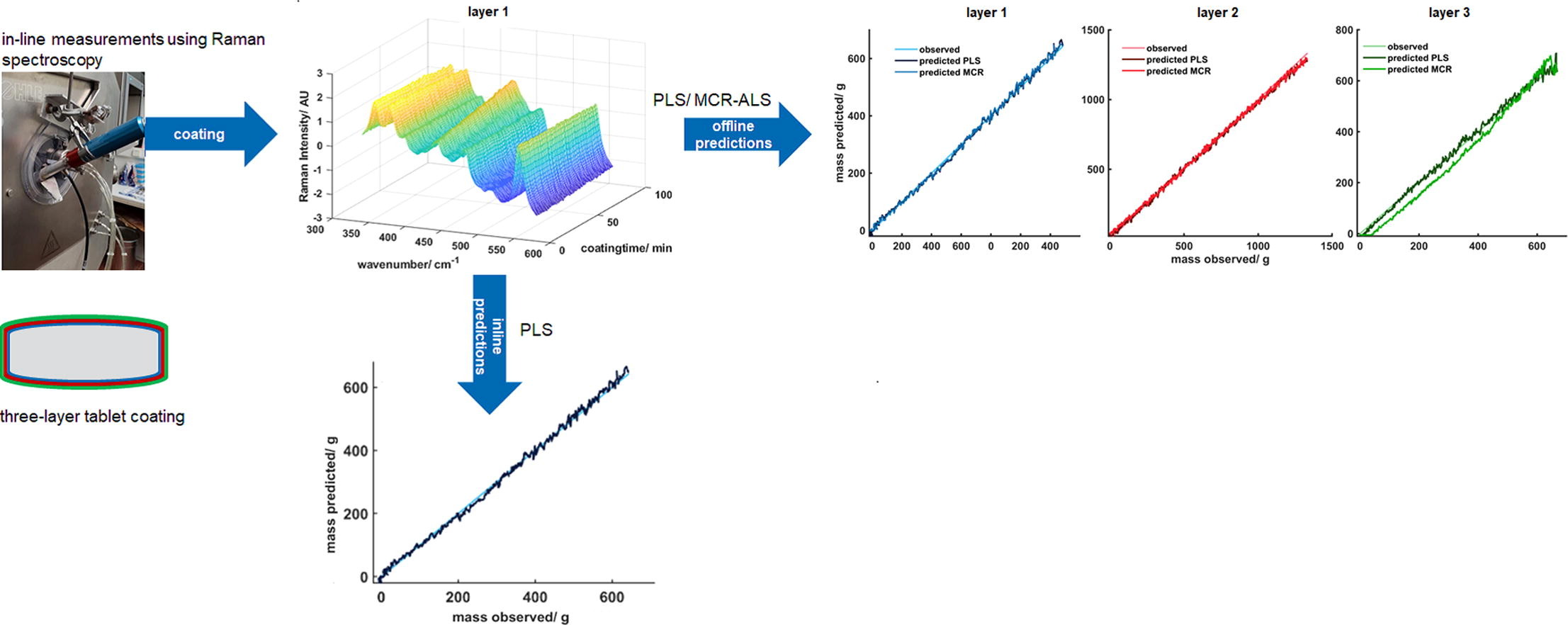

Raman spectroscopy was used as an in-line PAT tool to predict the applied coating mass of three different coating layers on caffeine cores. The different coating suspensions contained titanium dioxide in the anatase and rutile modification and iron oxide as Raman markers.

Partial least squares-regression (PLSR) and multivariate curve resolution-alternating least squares (MCR-ALS) were used for multivariate analysis. The acquired Raman spectra were correlated to the applied coating mass. MCR-ALS models were built and applied offline, while PLS-regression was implemented in the coating process to enable a real-time monitoring. Inline-measurements were optimized by a higher frequency of the spectral measurements and the implementation of a moving average. By PLS-regression analysis, all three layers could be predicted with root mean square errors (RMSEP) of less than 2.3 %. Inline implementation and optimization resulted in RMSEPs < 1.9 %. MCR-ALS analysis was able to predict the application of the first and the second layer with RMSEPs less than 2.9 %, but failed in predicting the application of the third layer. In conclusion, a real-time monitoring of a multi-layered coating process was achieved, PLS-regression was found to be superior to MCR-ALS and smoothing by the implementation of a moving average enhanced the predictability.

Author links open overlay panelJuliana Radtke, Peter Kleinebudde

European Journal of Pharmaceutics and Biopharmaceutics

Keywords: Multi-layered tablet coating, Raman spectroscopy, Real-time monitoring, Multivariate analysis, Process analytical technology (PAT)