A Comprehensive Review on Pharmaceutical Ready premix Coating Powder

Coating is an essential process in the pharmaceutical and nutraceutical industry. Earlier pharmaceutical formulation companies used to buy separate ingredients and mix them for colour coating, but nowadays many manufacturers are involved in making ready premix coating powder and this reduces the production cost, inventory requirement, facilities requirement and is easy to prepare coating solution etc. Ready premix coating material are made by single or blend of various polymers like Methacrylic Acid Co Polymer, HPMC, Ethyl Cellulose, PVA, carbomers, HPMC K4M, HPMC K 100 M, etc with plasticizers, pigments, opacifiers and other additives. It can enhance the appearance, protect from degradation, and optimize the performance of drug products. Ready premix coating powder can be reconstituted in any solvent system such as aqueous/hydro-alcoholic/organic as per the choice, needs of the formulator and the nature of the active ingredient in the formulation.

The increasing popularity of ready premix coating materials in the market promoted the creation of ready-to-use platforms by the manufacturer. Selection of ready-to-use premix coating ingredients in appropriate proportions makes the formulation successful.

Now many manufacturers of ready premix coating powders promote clean labels and provide replacement of undesired excipients such as titanium dioxide, silica, talc, magnesium stearate, synthetic colours, etc. to make the formulation consumer friendly. It is the responsibility of ready premix coating powder manufacturers to provide a premix coating that not only enhances the formulation but also meets the highest safety standards along with regulatory compliance.

To reduce product failure and development costs, real-time assessment of premix coating material quality is essential, especially for automated production. Therefore, implementation of Process analytical technology (PAT) is a recent trend for more effective monitoring and control of pharmaceutical unit operations.

Coating is also a technology-driven process, and the evolution of coated dosage forms relies on advancements in coating technology, equipment, analytical techniques, and coating materials. Many different coating technologies have been developed for solvent-based or solvent free coating processes. Each method has its own advantages and disadvantages and may require continuous technical refinement to ensure coating quality. Various process analytical techniques have been also developed for different levels of precision, capacity, and turnaround time. Each method has its own limitations and different predictive capability. In this article we are discussing only about premix coating materials.

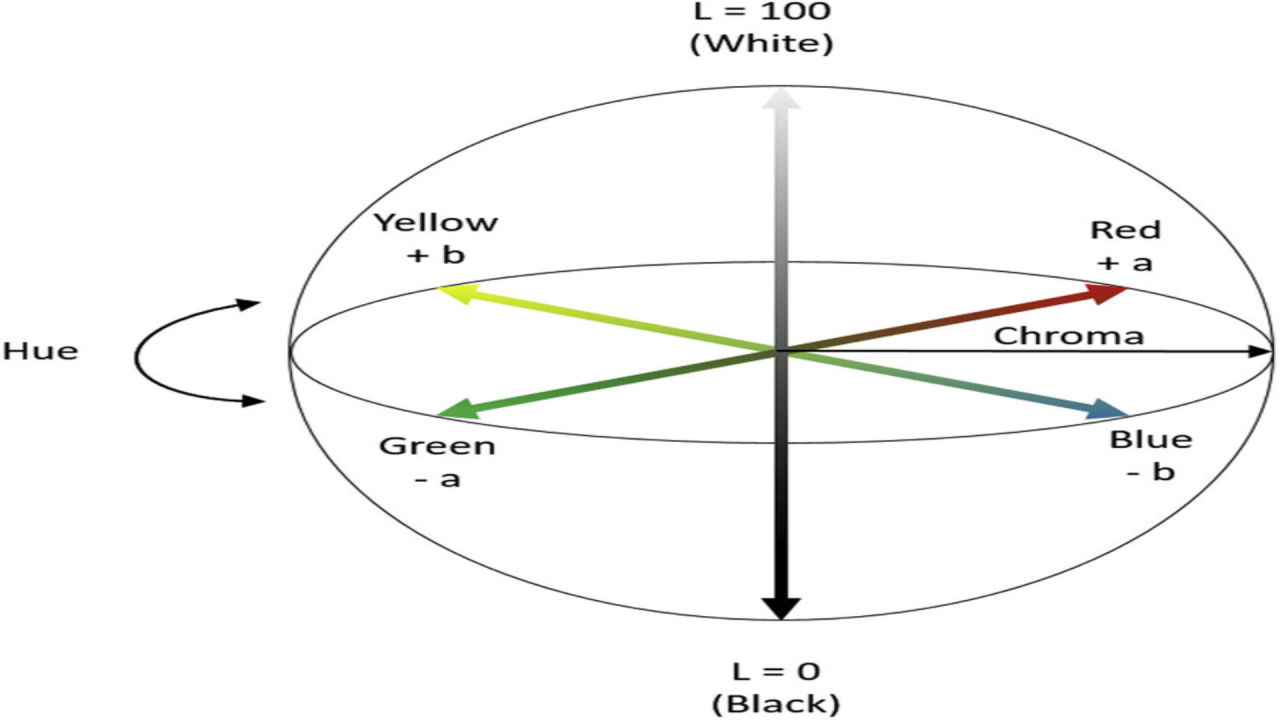

The pharmaceutical industry is very crucial, every component is chosen carefully. And, when it comes to the colour coding of the medicines, there is a huge set of guidelines to be followed. The guidelines are issued by relative authorities to keep a tab on the drug counterfeiting and usage of harmful colours. Many types of colourants are extensively used in the pharmaceutical industry. Some of the popularly used colours are white, blue, green, red and brown. These colours are made up of either natural or synthetic substances. Pharmaceutical colour measurement is crucial as a colour formulation for drugs require a lot of considerations.

Continue to read the full article on Pharmaceutical Ready premix Coating Powder

Source: Dr. Ajay Kumar Singh, 4. Februar 2024, (52) A Comprehensive Review on Pharmaceutical Ready premix Coating Powder | LinkedIn

Author:

Dr. Ajay Kumar Singh

Company Sigachi Pharma,

Assistant Vice President-Quality,

M. Sc(Gold Medallist-Organic Chemistry),

Ph.D.(Organic Chemistry)

Interested in more information about Sigachi or a specific Sigachi product?