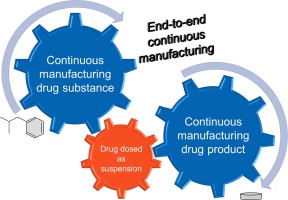

Simplified end-to-end continuous manufacturing by feeding API suspensions in twin-screw wet granulation

This study focussed on investigating the coupling of continuous manufacturing of drug substance and continuous manufacture of drug product. An important step in such an integrated end-to-end continuous manufacturing was envisioned by dosing the API as suspension into a twin-screw wet granulation process. To achieve this goal, a model drug substance (ibuprofen) was fed as a concentrated aqueous suspension (50% w/w) into a twin-screw granulator and compared against traditional solid feeding of the model drug substance to meet a target ibuprofen load of 60 % w/w in the formulation. Granulation and compaction behaviour were evaluated to determine the impact of feeding API as suspension in twin-screw wet granulation on the critical quality attributes of the drug product. It was demonstrated that the ibuprofen suspension feed is comparable with the ibuprofen dry blend feed in twin-screw wet granulation. Next to enabling end-to-end continuous manufacturing, API suspension feed in twin-screw wet granulation could afford a number of additional advantages including manufacturing efficiency by removing the drying step for API, or overcoming processing issues linked to the bulk properties of the API powder (e.g. flowability).

Read more on continuous manufacturing and twin-screw extrusion