Additional information

| Manufacturer |

Meggle |

|---|---|

| Quality |

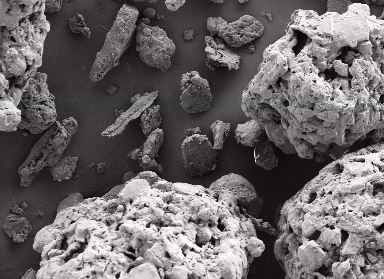

Compound of Lactose Monohydrate USP/NF, EP, JP, JP and Microcrystalline Cellulose USP/NF |

| Composition |

Compound of Lactose & MCC |

| Dosage Form |

Capsules, Tablets |

| Function |

Direct compression, dry granulation and capsule filling. Suitable for use in low as well as high dose formulations. Also, used as cores for coating |

Particle size distribution batch-to-batch consistency of MicroceLac® 100 by air-jet-sieving.Data obtained from a permanent in-process-controll (IPC) of subsequent batches over a time period of 12 months.

Particle size distribution batch-to-batch consistency of MicroceLac® 100 by air-jet-sieving.Data obtained from a permanent in-process-controll (IPC) of subsequent batches over a time period of 12 months.