3D Printing in Pharmaceutical and Medical Applications – Recent Achievements and Challenges

Growing demand for customized pharmaceutics and medical devices makes the impact of additive manufacturing increased rapidly in recent years. The 3D printing has become one of the most revolutionary and powerful tool serving as a technology of precise manufacturing of individually developed dosage forms, tissue engineering and disease modeling. The current achievements include multifunctional drug delivery systems with accelerated release characteristic, adjustable and personalized dosage forms, implants and phantoms corresponding to specific patient anatomy as well as cell-based materials for regenerative medicine.

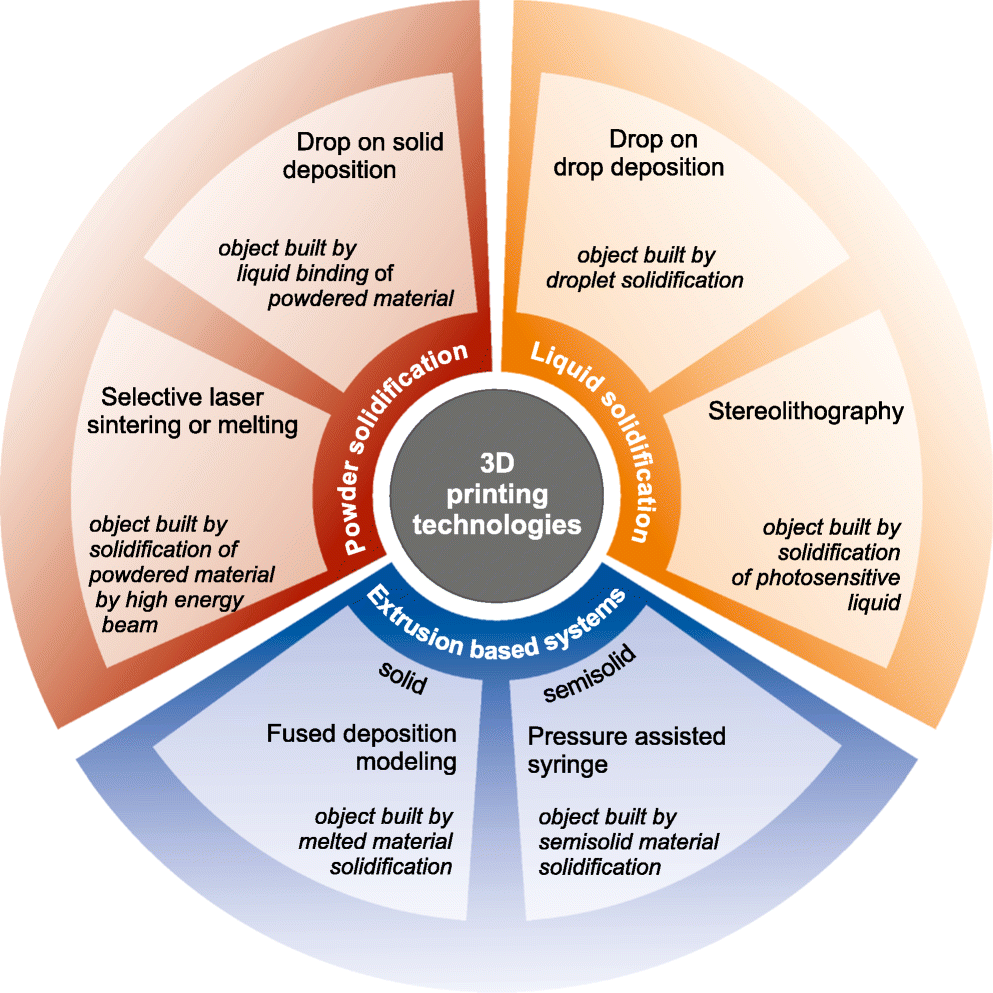

This review summarizes the newest achievements and challenges of additive manufacturing in the field of pharmaceutical and biomedical research that have been published since 2015. Currently developed techniques of 3D printing are briefly described while comprehensive analysis of extrusion-based methods as the most intensively investigated is provided. The issue of printlets attributes, i.e. shape and size is described with regard to personalized dosage forms and medical devices manufacturing. The undeniable benefits of 3D printing are highlighted, however a critical view resulting from the limitations and challenges of the additive manufacturing is also included. The regulatory issue is pointed as well.

Introduction:

There is a constant motivation towards new concepts in drug design, better understanding of material properties, manufacturing technology and processes that assures high quality of dosage forms. The diversity of physicochemical and biopharmaceutical characteristics of active pharmaceutical ingredients (APIs) have to be considered and studied through each stage of product development. Auxiliary substances need to be examined as well in order to manufacture of the desired dosage form.

Within last decade the patient-centric drug product development has been under considerable attention. It was focused on novel dosage forms and technological processes. Growing demand for customized devices combined with an expansion of technological innovation drives the major progress in personalized medicine expressed e.g. by the production of small series of individually-selected doses and tailor-made prostheses meet the anatomical needs of patients. Within many discoveries introduced into pharmaceutical and biomedical market, three-dimensional printing (3DP) is believed to be the most revolutionary and powerful. This technique is recognized as a versatile tool of precise manufacturing of various devices. It serves as a technology for developing novel dosage forms, tissues and organs engineering as well as disease modeling. Download the article as a PDF here

Article Information:

Interested to read the other articles of the 3D-printing series?

See also our Overview Video for the 3D Printing articles series