3D-printed Laponite/Alginate hydrogel-based suppositories for versatile drug loading and release

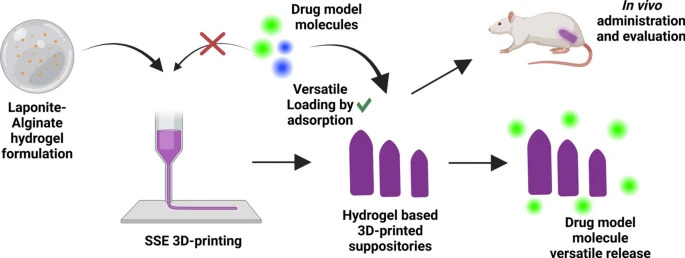

Traditional approaches to solid rectal therapies have halted progress, leading to a continual decline in the use of conventional suppositories. Additive manufacturing techniques have been recently explored as a suitable innovative tool for suppository fabrication. However, little advancement has been made in composition materials for 3D-printed suppository (3DPS) manufacturing and still, conventional vehicles are often used for construct fabrication, hindering the growth in the field. As a novelty, this study unveils a ground-breaking Laponite-alginate hydrogel-based 3DPS.

Interestingly, this study proposes a novel approach for loading drugs into the 3DPS employing for the first time the post-printing loading. Thus, a passive loading strategy of molecular models is developed, demonstrating the versatility and capacity to load molecules of different charges and molecular sizes within the matrix systems. This novel strategy allows adapting the load of a wide range of drugs into a single ink, which simplifies and speeds up the 3DPS technological development process for drugs with different physico-chemical properties.

Additionally, in this research, a displacement strategy of the three-dimensional Laponite matrices is developed in order to enhance the drug release capacity through the 3DPS and their disintegration capacity, resulting in a significant improvement of the drug diffusion through the hydrogel matrix and a rapid disintegration of the 3DPS. Finally, our study demonstrates that the obtained 3DPS have a suitable in vivo behavior, being non-obstructive and allowing the normal motility of the rats intestine.

Hydrogel ink preparation

Hydrogel ink was prepared as described in previous studies [9]. Briefly, Lap was dispersed with gentle stirring in deionized water at a concentration of 6% (w/v). Then, sodium alginate was added and dispersed into Lap dispersion reaching a final concentration of 1% (w/v). For a better alginate dispersion, an ultra-turrax system was employed for dispersion until no aggregates were observed in the final hydrogel. The formed hydrogel ink was transferred into 3 mL Luer-lock syringes and centrifuged at 3500 rpm for up to 15 min to remove bubbles.

Download the full study as PDF here: 3D-printed Laponite/Alginate hydrogel-based suppositories for versatile drug loading and release

or read it here

Munoz-Perez, E., Rubio-Retama, J., Cussó, L. et al. 3D-printed Laponite/Alginate hydrogel-based suppositories for versatile drug loading and release. Drug Deliv. and Transl. Res. (2024).

https://doi.org/10.1007/s13346-023-01506-5

Read more on “Alginates as Pharmaceutical Excipients” here: