Spray-Dried Chitosan Hydrogel Particles as a Potential Delivery System for Benzydamine Hydrochloride

Abstract

Introduction

Benzydamine hydrochloride is a salt form of the active compound benzydamine. It belongs to the group of non-steroidal anti-inflammatory drugs (NSAIDs), but instead of inhibiting COX1 or COX2, it suppresses the production of prostaglandin [1] and reduces pro-inflammatory cytokines [2]. Some of its most valuable effects are anti-inflammatory, local anesthetic, antimicrobial, and analgesic [3]. It is mostly used for the treatment of oral diseases such as sore throats, post-operative conditions, mucositis, etc. Due to its predominant local therapeutic activity, an appropriate mode and route of administration should be selected. Polymer-based structures such as planar films [4], multilayered films [5], wafers [2], and nano- and micro-particles [1,6] have been widely employed to achieve optimal local therapeutic effects with minimum side effects and local irritation.

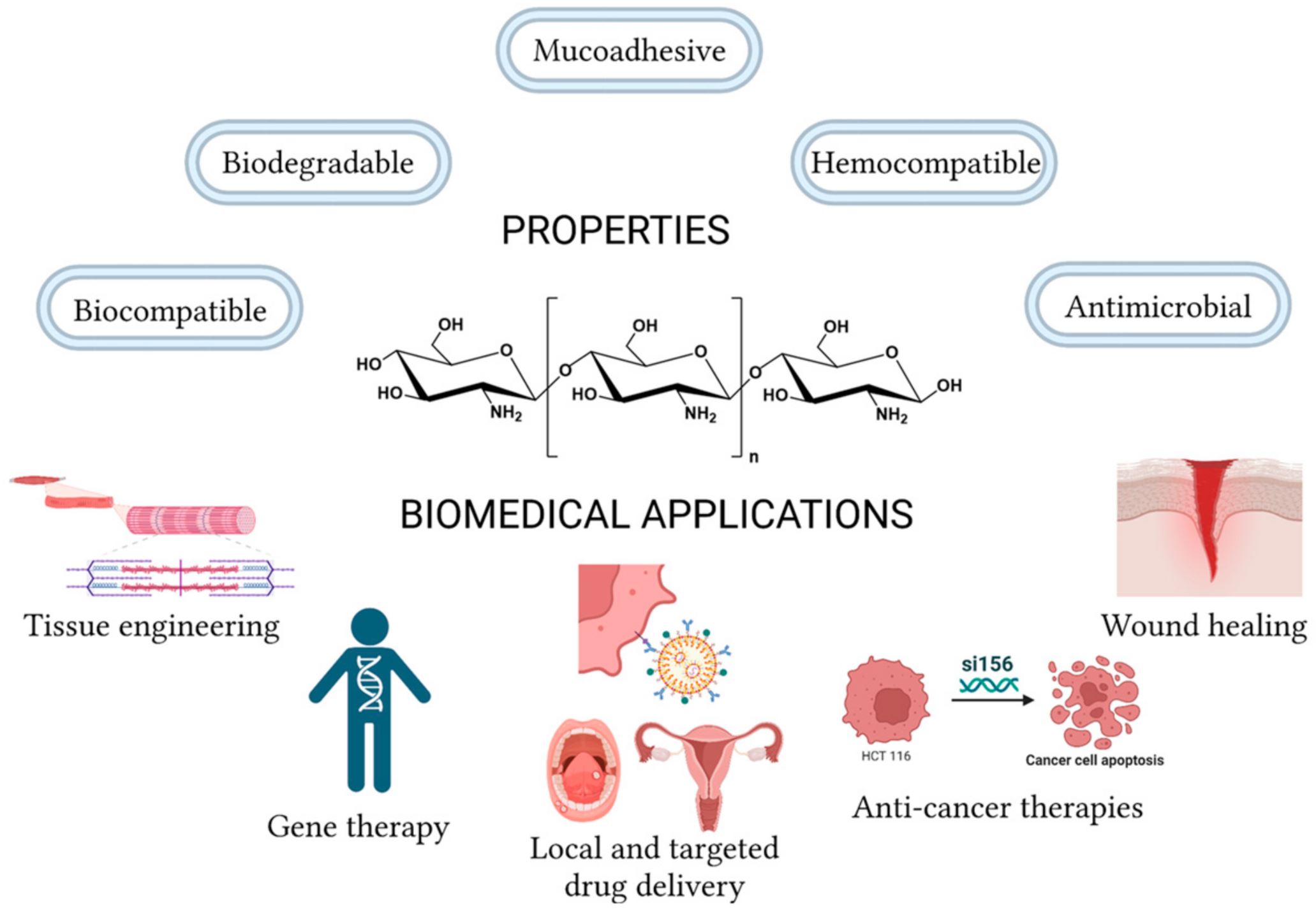

Microparticles are usually defined as spherical objects with diameters less than 1000 microns [7]. This kind of polymeric structure, especially the one based on biocompatible and/or biodegradable materials, has attracted the attention of researchers from many fields [8,9,10]. The importance of biocompatible soft gel-based structures in the field of biomedicine is quite high. They are desired and employed as non-conventional treatment approaches due to their high inherent hydrophilicity and ability to modify hydrophobic surfaces and structures combined with biomimicry [11]. Chitosan, a linear polysaccharide, is one of the most studied biocompatible polymers (Figure 1). It can be easily prepared as a gel structure by both physical and chemical cross-linking [12]. Being a weak polyelectrolyte, chitosan is highly sensitive to changes in the environment, and more specifically, to the pH conditions, making it a suitable base for smart stimuli-responsive material. In addition to its biodegradability and ability to form various types of structures, it is also mucoadhesive, enabling chitosan-based gels to stay longer in contact with the mucosal surface [13]. These features make chitosan a desirable material to obtain a drug delivery system for local administration into the oral cavity. As chitosan is able to form various types of structures, depending on the type of applied technique for preparation, its hydrogel structures may have many different types of architecture, such as homo- or heterogeneous spheres, mono- or polycore, or even matrixed types of distribution of the biologically active compound inside them [14].

Lyophilized wafers on the base of chitosan with different additions (HPMC, CMC, poloxamers) were obtained by Mehravaran et al. [2]. The formulated wafers were flexible and porous, and some of them ensured sustainable drug release for a period of 8 h. Also, benzydamine-loaded wafers accelerated the healing process of oral ulcers, fibroblast proliferation, and collagen synthesis. Planar structures such as single [4] or multilayer [5] films with chitosan have been examined as a potential benzydamine delivery platform. In the research published by Pechová et al. [4], casted chitosan films in combination with different plasticizers and maltodextrins were obtained. These additives had an impact on the mechanical properties and disintegration time of the film. The amount of loaded drug was affected by the film composition as well, varying around 3.1–3.4 mg in 6 cm2 film.

They conclude that the addition of small amounts of maltodextrin with a low dextrose equivalent improved some of the most important properties of their chitosan film. Viraneva et al. [5] evaluated porous PLA and/or PEC pads as bases for chitosan-casein multilayered film and their ability to encapsulate and release prolonged benzydamine. The parameter having the highest influence on the amount of encapsulated drug turned out to be the substrate composition. For both polarities, the PEC substrate had the highest values. Pads made of pure PLA and in excess of it, the release process was prolonged for 8 h.

The spray drying technique is a single-step method that is frequently chosen when micro- or nanoparticles are prepared. One of its biggest advantages is the fact that the produced product is in a direct dry state for significantly shorter times in comparison with the lyophilization process [15]. Another advantage is the ability to control the temperature throughout the preparation process without damaging either the biologically active compound or the polymer, while in some cases, for freeze drying, a cryoprotectant is needed [16]. Along with these facts, it is important to note that the drug and the polymer are in a common solution, not needing organic or toxic solvents to form a structure, unlike many times when the emulsion technique is employed [17].

As the oral mucosal membrane will be the desired site for potential treatment, it should be considered that cargo systems with sizes below 30 µm are able to adhere to the mucosal membrane [1]. Therefore, the aim of the present study is to prepare chitosan-based gel particles with sizes below 30 µm and load them with benzydamine hydrochloride. In our previous studies [6,18], we have developed polymeric particles using spray drying and ionic gelation techniques on the base of casein. In the case of spray-dried particles, the thermal instability of the protein has led to the need to conduct the preparation process at relatively low temperatures. This has resulted in problematic morphology or the inability to form a stable polymeric matrix. In the case of particles prepared by ionotropic gelation, the release of benzydamine hydrochloride was incomplete even after 72 h, making it unsatisfactory and long due to the chosen area of application. Undoubtedly, chitosan is the most examined biopolymer for local delivery of benzydamine. In previous research, Jiang et al. [1] have reported spray-dried particles loaded with BHCl into different types of modified chitosan-based systems. Despite its regular shape and thermal stability, it suffered from one main drawback—quite fast release, resulting in a complete drug release within only 30 min or even less.

In this study, our team aims to address the drawbacks that are reported for particle-type delivery systems, namely bad morphology and incomplete or too quick drug release. To achieve it, three different types of spray-dried particles on the base of chitosan, cross-linked chitosan via the ionic gelation technique with sodium tripolyphosphate (NaTPP), and chitosan with the addition of an excipient (mannitol), are developed. The main objective of this research is to evaluate the effect of the presence of a cross-linker or excipient on some of the most important particles’ characteristics, such as size, morphology, physicochemical properties, and thermal stability, along with drug release kinetics, concerning their potential as controlled drug delivery systems for benzydamine hydrochloride (BHCl).

Download the full article here: Spray-Dried Chitosan Hydrogel Particles as a Potential Delivery System for Benzydamine Hydrochloride

or read it here

Materials

Chitosan (Ch) (low molecular weight, 50–190 kDa, 75–85% deacetylated), sodium tripolyphosphate, D-mannitol, benzydamine hydrochloride, mucin (type II, from porcine stomach), Bradford reagent and dialysis membrane (MWCO 12,000 Da) were obtained from Sigma Aldrich (Sigma Aldrich Co., LLC, St. Louis, MO, USA). Other solvents (methanol, distilled water, acetic acid) were used with analytical grade of purity.

Milenkova, S.; Ambrus, R.; Mukhtar, M.; Pilicheva, B.; Marudova, M. Spray-Dried Chitosan Hydrogel Particles as a Potential Delivery System for Benzydamine Hydrochloride. Gels 2024, 10, 189. https://doi.org/10.3390/gels10030189

See our next webinar and register here: