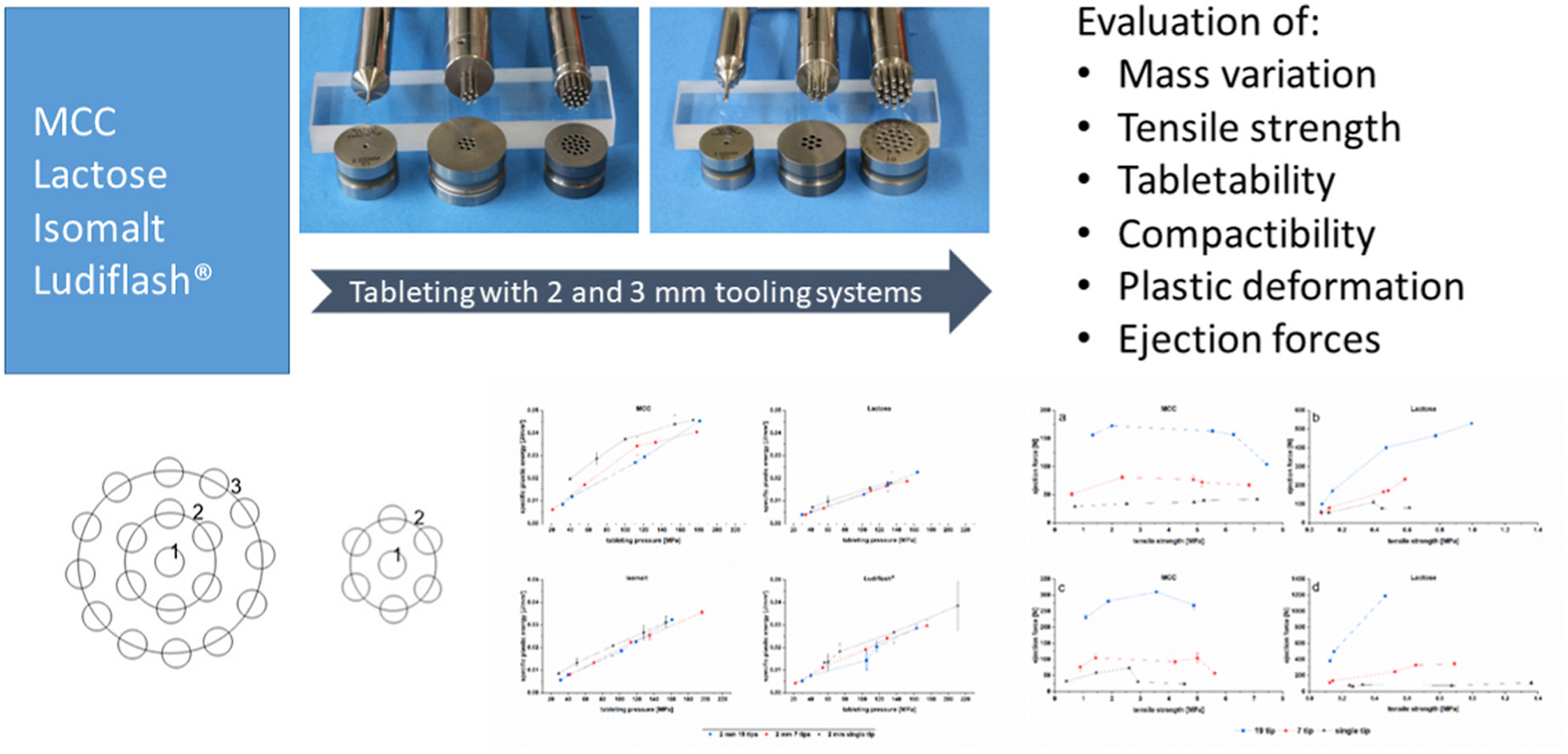

Manufacturing of mini-tablets. Focus and impact of the tooling systems

Mini-tablets are gaining importance for the pharmaceutical industry as several clinical studies and organizations emphasize the benefits for special patient groups such as paediatrics. Mini-tablets can be manufactured on tablet presses using special tooling systems. For industrial purposes often multi-tips are used, in order to achieve a high yield during production time. However, the effect of the used tooling system on quality attributes is not fully investigated yet. Therefore, 2 and 3 mm mini-tablets have been manufactured on a compaction simulator using single-tip, 7-tip and 19-tip punches and industrial relevant excipients. Mass variation and tensile strengths the mini-tablets were evaluated as critical quality attributes. Additionally, the deformation behaviour and specific plastic energy (SPE) were analyzed. For evaluating the tableting performance tabletability and compactibility plots were created. With all used tooling systems significant differences in mass were observed for all excipients, despite of same filling procedure and filling heights. In-die Heckel plot revealed that the lowest yield pressures and in most cases the highest SPE were obtained using a single-tip. No major differences were found regarding tabletability but in most cases compactibility was improved using a 19-tip tooling. On the other hand, with a 19-tip the highest ejection forces were measured and targeted tensile strengths could not be achieved.

About this article: Ard Lura, Jörg Breitkreutz, Manufacturing of mini-tablets. Focus and impact of the tooling systems,

Journal of Drug Delivery Science and Technology, 2022, 103357, ISSN 1773-2247, https://doi.org/10.1016/j.jddst.2022.103357. (https://www.sciencedirect.com/science/article/pii/S1773224722002672)