Parteck® LM Excipient System – Reduce complexity in your formulation and optimize results

Discover our, Merck, new Parteck® LM Excipient System: This exceptional product offers excellent flow properties, ensuring reliable dosing in both batch and continuous processes. With its consistent dosing and robust, constant mixing times, Parteck® LM Excipient System supports a consistent performance of the process and guarantees a high-quality final formulation.

What’s more, Parteck® LM Excipient System is serving as filler, binder, and lubricant, all rolled into one. Streamline your solid dose formulations with this versatile solution!

Solving your handling issues in lubrication

Self-lubricated filler-binder for batch and CM use

Lubrication with most widely used magnesium stearate has its difficulties both in batch and continuous manufacturing of tablets. Overlubrication is often cited as an issue and dosing of the poorly flowing Mg-Stearate is an issue for continuous manufacturing (CM). Parteck® LM Excipient System will give you the perfect flow.

- Parteck® LM is easy to dose in a continuous manufacturing line.

- It is robust and helps reduce mixing times.

- Parteck® LM is a combination of mannitol and Mg-Stearate – only one product but comprising three functions: Filler + binder + lubricant.

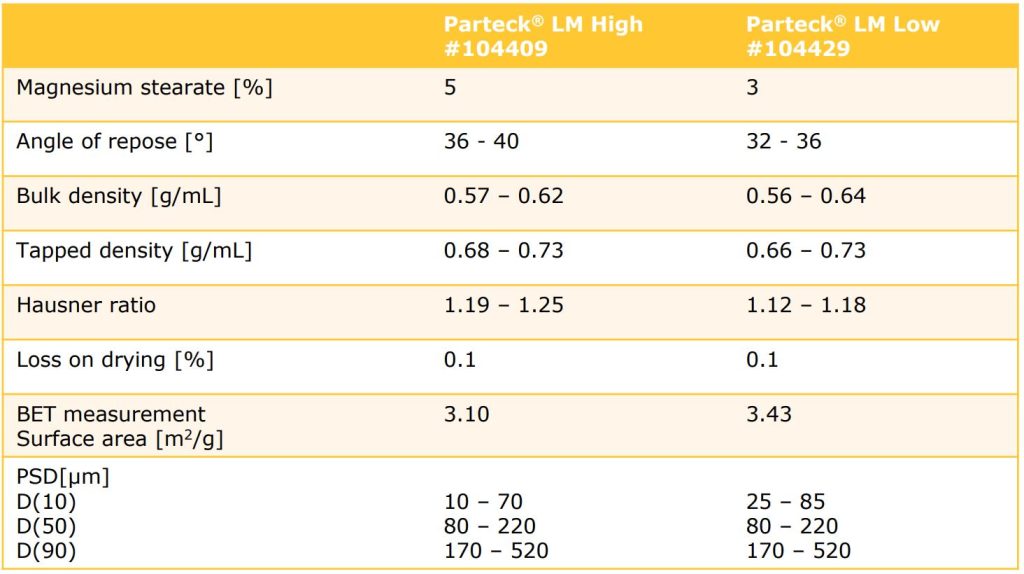

- Two grades are offered: Parteck ® LM Low for low dose applications and less requirement for lubrication.

- Parteck ® LM High will address higher API loads and more demanding cases with regards to lubrication.

- Parteck® LM is applicable in direct compression, wet granulation, roller compaction or dry granulation as well as capsule filling.

- It comes with the Emprove® Program providing comprehensive and thorough documentation, supporting supply chain transparency, risk mitigation and qualification processes, thus accelerating time-to-market.

Key parameters Parteck® LM

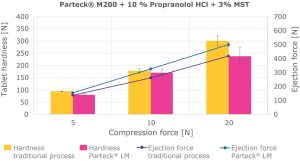

Process efficiency in continuous and batch manufacturing

In both batch and continuous manufacturing processes, lubrication poses a real challenge. The widely used magnesium stearate, though popular, presents dosing issues due to its poor flowability. Over-lubrication often leads to lower tablet hardness and increased friability, while under-lubrication can result in capping and sticking of tablets to the die.

Parteck® LM in Continuous Manufacturing

Composed of raw materials complying to major pharmacopeias, Parteck® LM will deliver identical results as with the traditional formulation procedure of mixing of excipient, API and lubricant in a subsequent step – but with the ease of use of just one single dosing and mixing operation.

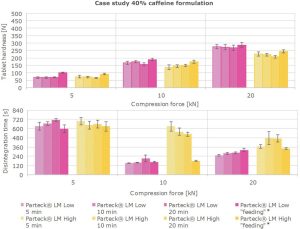

Parteck® LM in Batch Manufacturing

No impact of mixing time and feeding. Using Parteck® LM results in a robust product demonstrating constant tablet hardness and comparable DT, not impacted by further processing.

See the full technical brochure on “Parteck® LM Excipient System” here

(click the picture to download the brochure)

Source: Merck technical brochure “Parteck® LM Excipient System”, website Parteck® LM low EMPROVE® ESSENTIAL | Sigma-Aldrich (sigmaaldrich.com)

Do you need more information or a sample of Merck excipients?