Radial die wall pressure measurement

Instrumented die is used to measure maximum die-wall pressure (MDP) and residual die-wall pressure (RDP) during powder compaction. This document from MEDELPHARM aims to provide a methodology to characterize powders with this device.

Instrumented die is used to measure maximum die-wall pressure (MDP) and residual die-wall pressure (RDP) during powder compaction. This document from MEDELPHARM aims to provide a methodology to characterize powders with this device.

Introduction

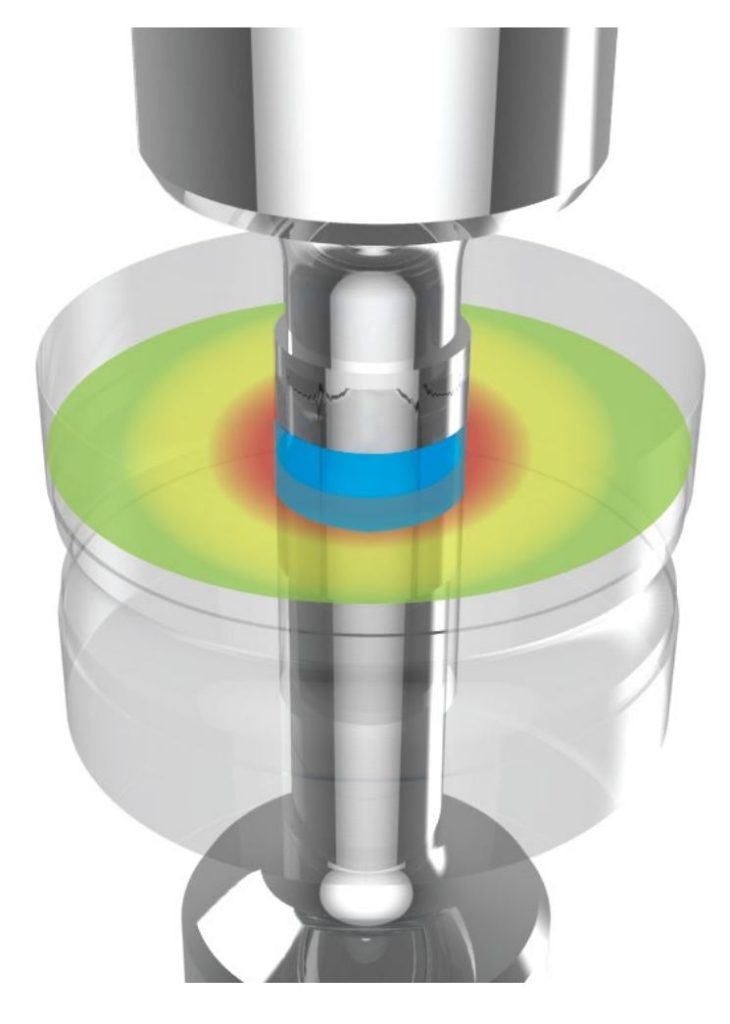

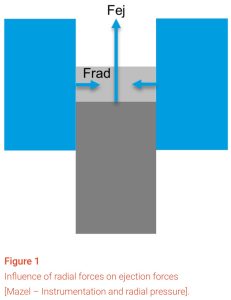

During tablet development, people study ejection forces (Fej) in order to avoid tablet defects during tablet manufacturing. Some of those defects, like lamination and capping are said to be linked to high ejection forces. High ejection forces can be induced by high die-wall force or friction between powder and die-wall (Frad =Force radial). To determine the origin of this phenomenon it can be useful to measure radial pressure. Indeed standard compaction studies are made by analysis of the vertical forces on upper and lower punches. However, the die also applies its own pressure to the powder horizontally. This strain, called the die wall pressure, is said to be the hidden variable of the compression.

The pressure of the powder to the die (Radial pressure) is computed by dividing the force by this surface area).

The pressure of the powder to the die (Radial pressure) is computed by dividing the force by this surface area).

Installing an instrumented die on your STYL’One allows you to measure the die-wall pressure and to perform an extensive characterization of your products. The instrumented die can be used to measure Maximum Die-wall Pressure (MDP) (at the compression peak) and Residual Die-wall Pressure (RDP) (when the axial

pressure is removed).

Instrumentation

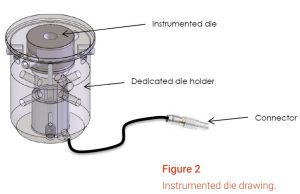

As a standard, the instrumented die is plug-and-play device mounted on an 11.28 mm diameter round die with its own set of punches. The instrumented-die is an accessory of STYL’One.

As a standard, the instrumented die is plug-and-play device mounted on an 11.28 mm diameter round die with its own set of punches. The instrumented-die is an accessory of STYL’One.

The calculation of the die wall pressure uses the die wall signal (radial) and the surface area between the compact and the die.

The surface is automatically computed by the software, by taking into account the thickness (distance between the punches) and the perimeter of the die.

Methodology

The medium axis of the compression zone is ideally set at 6mm, where the strain gage is located but different depths of compression can be used and the Analis software will perform the correction thanks to the abacus generated during the calibration.

The instrumented die can be used to measure die-wall pressure up to 300MPa. Above some damage can occur to the die, so a safety threshold exists on the software to stop the machine if the stress reaches this limit.

To compare products, a compression speed, a compression pressure and a corrected thickness have to be fixed. At

MEDELPHARM Science Lab, a 200MPa axial pressure and a 3mm corrected thickness are targeted. As a consequence, the filling height has to be adjusted step by step to meet those targets. Once the settings are found, two others replicates are performed in order to avoid outliners. For characterization purpose the V-Shape cycle has to be used. The first measurements can be performed at low speed (3mm/s) and some can be performed at high speed (300mm/s). Indeed the speed might have an influence on the deformation behavior.

See the full brochure “Radial die wall pressure measurement” here:

(click the picture to download the brochure)

Do you need some details or more information? Just fill in the contact form:

Source: MEDELPHARM brochure “Radial die wall pressure measurement”

STYL’One Evo key benefits:

- Versatile

- Standard tooling

- Ideal for small amount of material

- Quick product and tooling changeover

- Easy to clean – easy to handle

- Simulation of any rotary tablet press

- User-friendly HMI for fast experiment setup and

results with automatic studies