Effect of lipid composition on RNA-Lipid nanoparticle properties and their sensitivity to thin-film freezing and drying

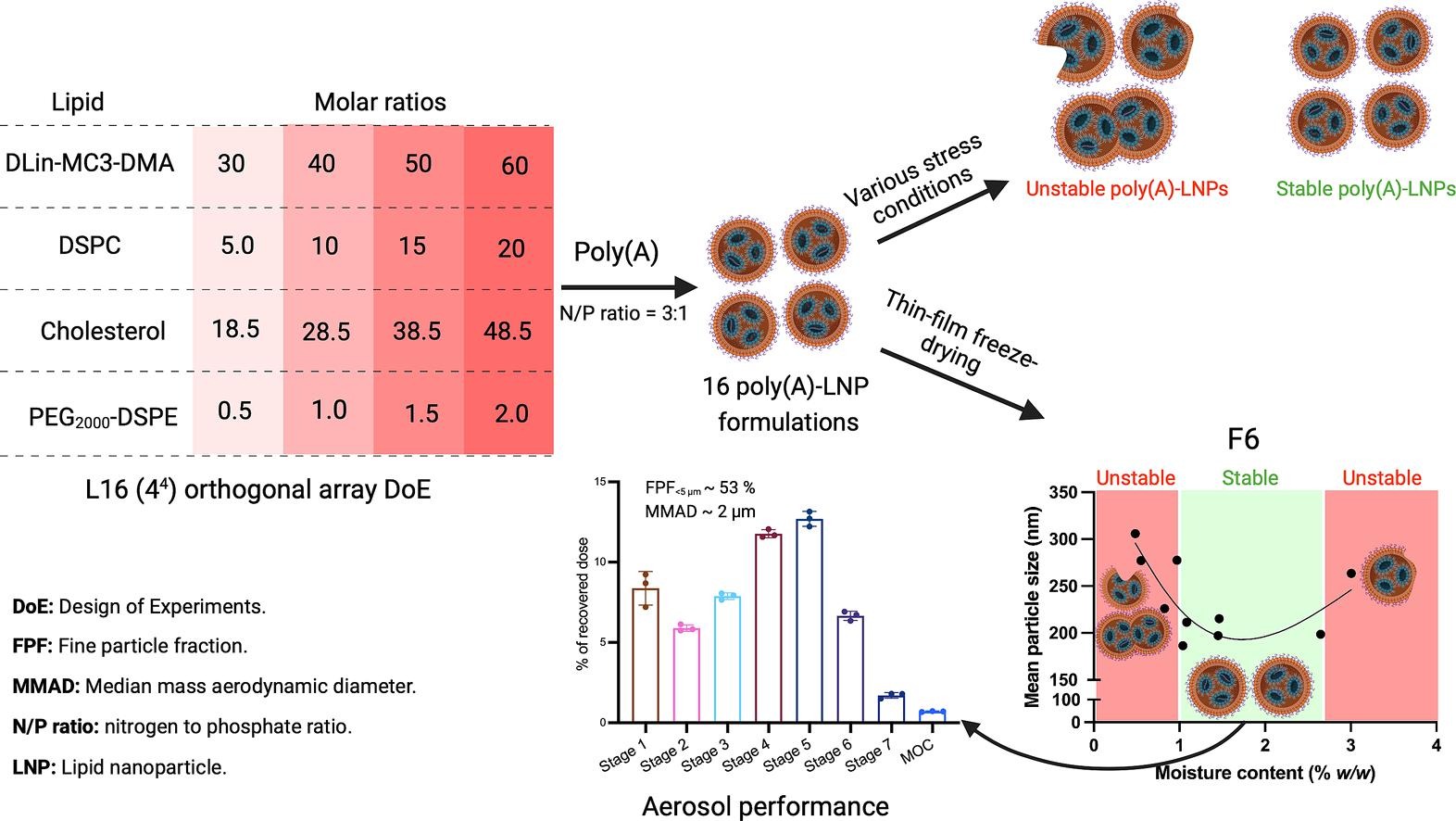

A library of 16 lipid nanoparticle (LNP) formulations with orthogonally varying lipid molar ratios was designed and synthesized, using polyadenylic acid [poly(A)] as a model for mRNA, to explore the effect of lipid composition in LNPs on (i) the initial size of the resultant LNPs and encapsulation efficiency of RNA and (ii) the sensitivity of the LNPs to various conditions including cold storage, freezing (slow vs. rapid) and thawing, and drying. Least Absolute Shrinkage and Selection Operator (LASSO) regression was employed to identify the optimal lipid molar ratios and interactions that favorably affect the physical properties of the LNPs and enhance their stability in various stress conditions. LNPs exhibited distinct responses under each stress condition, highlighting the effect of lipid molar ratios and lipid interactions on the LNP physical properties and stability. It was then demonstrated that it is feasible to use thin-film freeze-drying to convert poly(A)-LNPs from liquid dispersions to dry powders while maintaining the integrity of the LNPs. Importantly, the residual moisture content in LNP dry powders significantly affected the LNP integrity. Residual moisture content of ≤ 0.5% or > 3–3.5% w/w negatively affected the LNP size and/or RNA encapsulation efficiency, depending on the LNP composition. Finally, it was shown that the thin-film freeze-dried LNP powders have desirable aerosol properties for potential pulmonary delivery. It was concluded that Design of Experiments can be applied to identify mRNA-LNP formulations with the desired physical properties and stability profiles. Additionally, optimizing the residual moisture content in mRNA-LNP dry powders during (thin-film) freeze-drying is crucial to maintain the physical properties of the LNPs.

Introduction

Messenger RNA (mRNA)-based therapeutics have various potential clinical applications including protein replacement therapy (Melamed et al., 2023), vaccination (Pardi et al., 2020), cancer immunotherapy (Hewitt et al., 2019), tissue regeneration (Yu et al., 2023a), and gene editing (Qiu et al., 2021). The clinical utility of mRNA therapeutics is evidenced by the approval of mRNA-based coronavirus disease (COVID-19) vaccines (i.e., Comirnaty® and Spikevax®) by the U.S. Food and Drug Administration (FDA). Vaccines based on mRNA avoid the potential safety concerns associated with other nucleic acid-based vaccines (e.g., DNA vaccine) such as potential genome integration. Additionally, mRNA can be synthesized by an in vitro transcription process (IVT mRNA); thus, mRNA vaccines have high modularity and large manufacturing capabilities (Weng et al., 2020). Comirnaty® and Spikevax® are based on N1-methyl-pseudouridine-modified, IVT mRNA encoding the spike glycoprotein of severe acute respiratory syndrome coronavirus-2 (SARS-CoV-2) (Morais et al., 2021). Pseudouridine-containing mRNA has higher stability and translation capacity than unmodified mRNA (Karikó et al., 2008).

However, structural modifications of mRNA molecules cannot overcome the obstacle of mRNA cellular internalization (Schoenmaker et al., 2021). Ultimately, there is a need for an efficient delivery system that can protect mRNA molecules against degradation by RNase enzymes, enable its internalization into target cells, and release the mRNA molecules from the endosomes to the cytoplasm where translation into functional proteins is initiated (AboulFotouh et al., 2021). LNPs are currently the leading delivery systems for RNA (e.g., Comirnaty®, Spikevax® and Onpattro®, which is comprised of siRNA-LNPs). LNPs are typically composed of four lipids: an ionizable lipid, a polyethylene glycol-functionalized lipid (PEG-lipid), an amphiphilic phospholipid, and cholesterol. The ionizable lipid is crucial for encapsulating the anionic mRNA during LNP synthesis at low pH, and for facilitating endosomal release as it undergoes protonation in the acidic environment of the endosomes (pH 4.5–6.8) (Granot and Peer, 2017, Hassett et al., 2019). Other lipid components improve the LNP properties including LNP stability, delivery efficiency, tolerability and biodistribution (Hou et al., 2021). For instance, cholesterol enhances the LNP stability via filling in the gaps between the phospholipids and thereby influencing the membrane integrity and rigidity (Cheng and Lee, 2016). The PEG-lipid controls the particle size and zeta potential and further enhances the particle stability via formation of a steric barrier against aggregation (Kim et al., 2021). Phospholipids promote fusion with cellular and endosomal membranes and therefore facilitate cellular uptake and endosomal release (Hajj and Whitehead, 2017). Additionally, phospholipids with high transition temperatures such as 1,2-distearoyl-sn-glycero-3-phosphocholine (DSPC, transition temperature of 55 °C) can stabilize the LNP structure via formation of a lamellar phase (Koltover et al., 1998), and increasing the rigidity and reducing the permeability of the LNP membrane (Roces et al., 2020).

A major challenge for mRNA-LNP products is that they often need to be stored at (ultra)cold temperatures for the entire product shelf life (i.e., −90 to −60 °C for 12–18 months for Comirnaty® and −50 to −15 °C for 12 months for Spikevax®). The ultracold storage requirements present a significant challenge for mRNA-LNP products (AboulFotouh et al., 2021). On the other hand, Onpattro® is stable for 27 months at 2–8 °C (Suzuki and Ishihara, 2021). Onpattro® is comprised of a chemically modified, highly stable, double-stranded small interfering RNA (siRNA) formulated in LNPs composed of (6Z,9Z,28Z,31Z)-heptatriacont-6,9,28,31-tetraene-19-yl 4-(dimethylamino) butanoate (DLin-MC3-DMA), DSPC, cholesterol and α-(3′-{[1,2-di(myristyloxy)propanoxy]carbonylamino}propyl)-ω-methoxy, polyoxyethylene (PEG2000-C-DMG) at molar ratios of 50:10:38.5:1.5 (Schoenmaker et al., 2021). Therefore, it was suggested that mRNA is the bottleneck of mRNA-LNP stability (Schoenmaker et al., 2021). The siRNA in Onpattro® is a 21 rigid RNA duplex while the mRNA molecules in the COVID-19 vaccines are long, flexible, single-stranded RNA with > 4000 nucleotides (Suzuki and Ishihara, 2021). Additionally, the locations of siRNA vs. mRNA molecules within the LNPs are different, which may affect the LNP stability (Viger-Gravel et al., 2018). Therefore, it is not surprising that the optimized formulation parameters are different between mRNA and siRNA (Kauffman et al., 2015). Ultracold storage temperatures may be required to protect the mRNA against hydrolysis. The overall stability of an mRNA-LNP product is likely to be determined by three main factors: (i) the molecular structures of lipid components and their interactions with the mRNA payload (Oude Blenke et al., 2023), (ii) formulation excipients (e.g., buffers and cryoprotectants) (Oude Blenke et al., 2023), and (iii) downstream processing (e.g., freezing and/or drying) and storage conditions (Ai et al., 2023).

Various approaches have been explored to address the ultracold temperature storage requirements of mRNA-LNPs including the use of stabilizing excipients (Zhang et al., 2020b, Zhao et al., 2020), freeze-drying (Ai et al., 2023, Muramatsu et al., 2022), as well as development of new lipid formulations with improved stability at higher temperatures (Oude Blenke et al., 2023). However, these studies were completed with different LNP compositions. For instance, during freeze-drying the excipients and lyophilization cycles are optimized and tailored to the lipid components of the LNPs on a case-by-case basis (Zhao et al., 2020). Hence, a more comprehensive understanding about the stability of mRNA-LNPs of different compositions and under various conditions is needed so that future LNP development can be less reliant on a trial-and-error approach.

Herein, we hypothesize that changing the molar ratios of various lipid components will result in LNPs with distinctive physical properties and stability profiles against various stress conditions. To test this hypothesis, a library of 16 LNP formulations with orthogonally varying lipid molar ratios was designed and studied. LNP formulations were loaded with poly(A). Poly(A) was selected as a model for mRNA due to its simple structure and consistent biophysical properties (Roces et al., 2020, Yanez Arteta et al., 2018). Therefore, it is a suitable cargo for studying the effect of lipid composition on the physical properties and stability profiles of mRNA-LNPs. Poly(A) is heterogenous in terms of molecular weight (i.e., 700–3,500 kDa) and chain length (i.e., 2,100–10,000 nucleotides). For a comparison, the SARS-CoV-2 spike protein mRNA molecules in Comirnaty® and Spikevax® are about 4,000 nucleotides (Granados-Riveron and Aquino-Jarquin, 2021, Suzuki and Ishihara, 2021). We used minimal resource, in vitro stability-indicating assays including dynamic light scattering and encapsulation efficiency, to study the effect of LNP composition on (i) the initial size of the resultant LNPs and the encapsulation efficiency of poly(A) in the LNPs and (ii) the robustness/sensitivity of the LNPs to various stress conditions including storage at 4 °C, freezing-thawing, and drying stresses. LASSO regression (McEligot et al., 2020), a machine learning regression tool, was employed to identify the optimal molar ratios and interactions of lipid components that can affect the particle size of the LNPs and the encapsulation efficiency of the RNA and enhance the stability of the LNPs against various stress conditions. Interestingly, we found that LNPs exhibited distinct responses under each stress condition, which signifies the effect of lipid component ratios and lipid interactions on LNP physical properties and stability.

Finally, we investigated the feasibility of engineering aerosolizable dry powders of poly(A)-LNPs using the thin-film freeze-drying technology (AboulFotouh et al., 2022b, Hufnagel et al., 2022b). Thin-film freeze-dried powders are often brittle matrices with low densities and large specific surface areas, and therefore possess desirable aerosol properties (Sahakijpijarn et al., 2020). The thin-film freeze-drying technology has been used to generate dry powders of large molecules such as monoclonal antibodies (Hufnagel et al., 2022b), subunit protein vaccines (AboulFotouh et al., 2022a, AboulFotouh et al., 2022b), and siRNA in solid lipid nanoparticles (Wang et al., 2021). In this study, dry powders of poly(A)-LNPs were successfully engineered using thin-film freeze-drying while maintaining the physical properties of the poly(A)-LNPs (e.g., LNP size, morphology, and structure, RNA encapsulation efficiency, etc.) and the aerosol performance properties of a selected dry powder were evaluated.

Orthogonal array design of experiments (DoE)

The effect of LNPs’ compositions on their physical properties, cold storage stability, and sensitivity to freezing and drying stresses was studied using an L16 (44) orthogonal array DoE (Li et al., 2015). DLin-MC3-DMA (MedChem Express, Monmouth Junction, NJ), DSPC (Avanti Polar Lipids, Inc., Alabaster, AL), cholesterol (Sigma-Aldrich, St. Louis, MO) and 1,2-distearoyl-sn-glycero-3-phosphoethanolamine-N-[amino(polyethylene glycol)-2000] ammonium salt (PEG2000-DSPE, MW of about 2790

Read more

Khaled AboulFotouh, Benjamin Southard, Huy M. Dao, Haiyue Xu, Chaeho Moon, Robert O. Williams III, Zhengrong Cui, Effect of lipid composition on RNA-Lipid nanoparticle properties and their sensitivity to thin-film freezing and drying, International Journal of Pharmaceutics, Volume 650, 2024, 123688, ISSN 0378-5173,

https://doi.org/10.1016/j.ijpharm.2023.123688.