Simulation of roller compaction by combination of a compaction simulator and oscillating mill – A material sparing approach

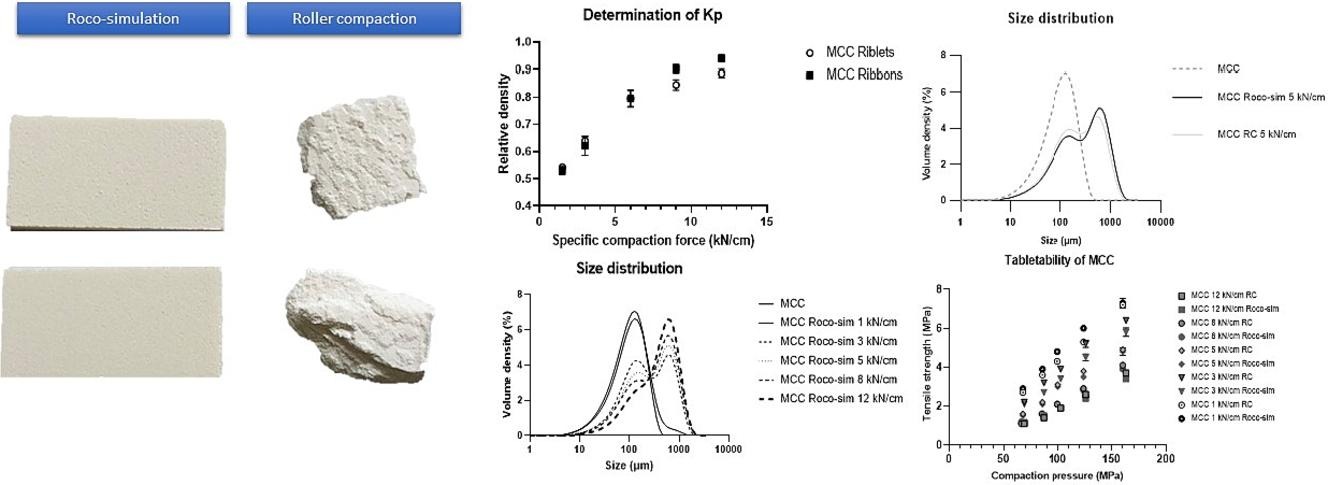

This study investigates the feasibility of a compaction simulator and oscillating mill to mimic a roller compactor as a material sparing approach for process development. Microcrystalline cellulose and dicalcium phosphate dihydrate were selected to represent soft and hard materials, respectively. The relative density of ribbons and riblets was determined using a pycnometer and granules size distribution was determined by laser diffraction. Tablet tensile strength and relative density were determined using a hardness tester and pycnometer, respectively. This study showed that the relative density of riblets and ribbons were similar between 1 and 12 kN/cm, which indicates that the compaction simulator adequately mimics the compaction of the roller compactor using a Kp of 1. The size distribution of granules produced by the oscillating mill and roller compactor were similar, which indicates that the oscillating mill adequately mimics the roller compactor when using a similar gap and sieve design. Finally, the tablet tensile strength and relative density were similar independent of the applied granulation method and deformation behaviour of the material. In conclusion, the use of a compaction simulator and an oscillating mill in combination adequality mimics the roller compactor, which ultimately can save large amounts of material and time during process development.

2.1. Materials

Microcrystalline cellulose (Avicel PH102) was obtained from FMC (Philadelphia, PA, United States), dicalcium phosphate dihydrate (Emcompress Premium) was obtained from Rettenmaier (Holstebro, Denmark) and magnesium stearate (Ligamed MF-2-V) was obtained from Peter Greven (Bad Münstereifel, Germany). The materials were used as received, however DCPD was mixed with 1% w/w magnesium stearate to avoid adhesion in the equipment whereas lubrication could be avoided when using MCC.

Download the full study as PDF here: Simulation of roller compaction by combination of a compaction simulator and oscillating mill – A material sparing approach

or read it here

Layla Hassan, René Jensen, Andrew Megarry, Lasse I. Blaabjerg, Simulation of roller compaction by combination of a compaction simulator and oscillating mill – A material sparing approach, International Journal of Pharmaceutics, Volume 644, 2023, 123281, ISSN 0378-5173,

https://doi.org/10.1016/j.ijpharm.2023.123281.