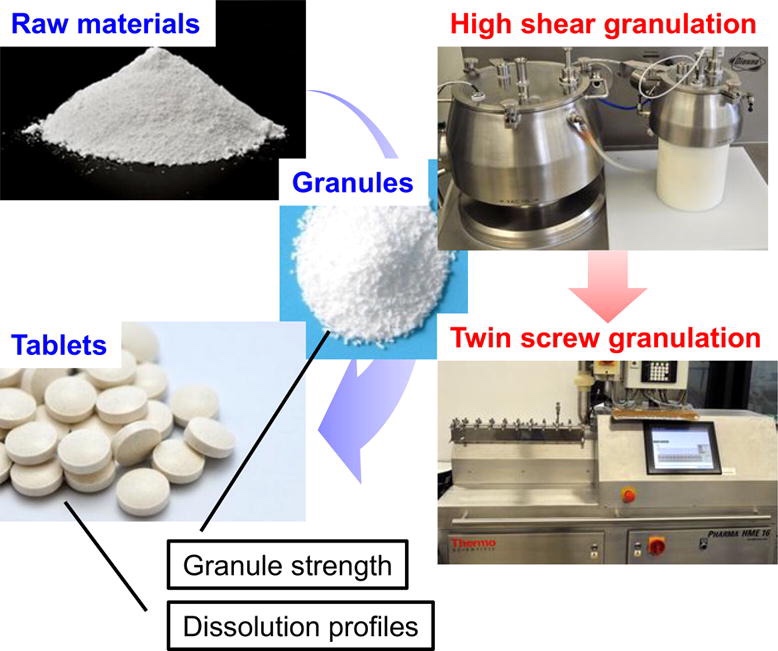

Switch of tablet manufacturing from high shear granulation to twin-screw granulation using quality by design approach

This study aimed to transfer a high shear granulation (HSG) process to a twin-screw granulation (TSG) process while maintaining equivalent dissolution profiles. Ibuprofen (IBP) was used as poorly soluble model drug. Granules were obtained by HSG or TSG according to a full factorial design.

The liquid-to-solid ratio and wet massing time (HSG) or powder throughput (TSG) were selected as factors. The granules were compressed to tablets with immediate release and a drug load of 50% (w/w). Quality attributes (QAs) of the granules, especially the granule strength (GS), and the resulting tablets were evaluated. The effect of process parameters on the QAs was statistically analyzed. The comparison of HSG tablets with TSG tablets revealed that TSG tablets showed higher tensile strength and lower ejection force than HSG tablets.

The dissolution profiles of the tablets in different pH media were also evaluated. Equivalent dissolution profiles in all four media (e.g., f2 values ≥ 54 in pH5.5) were obtained by adjusting process parameters. It was concluded that the GS was the most important QA for dissolution. Continue reading here