Managing active pharmaceutical ingredient raw material variability during twin-screw blend feeding

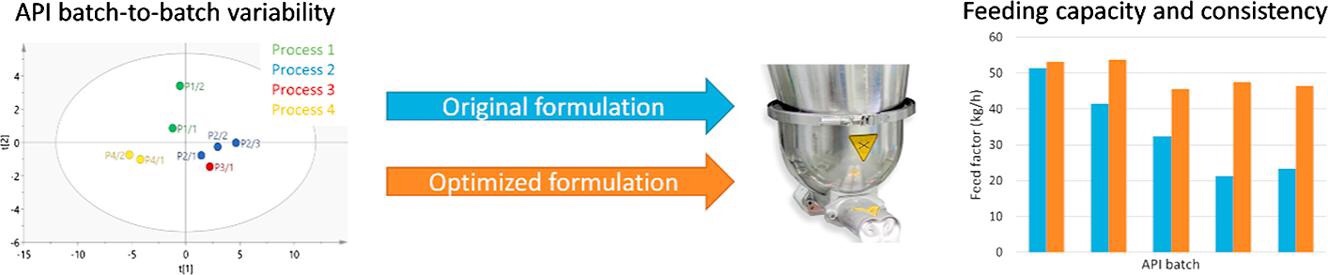

Continuous powder feeding is a critical step in continuous manufacturing of solid dosage forms, as this unit operation should ensure the mass flow consistency at the desired powder feed rate to guarantee the process throughput and final product consistency. In this study, twin-screw feeding of a pharmaceutical formulation (i.e., blend) existing of a highly dosed very poorly flowing active pharmaceutical ingredient (API) leading to insufficient feeding capacity was investigated. Furthermore, the API showed very high batch-to-batch variability in raw material properties dominating the formulation blend properties. Formulation changes were evaluated to improve the flowability of the blends and to mitigate the impact of API batch-to-batch variability on the twin-screw feeding. Herewith, feeding evaluation tests and an extensive material characterization of the reformulated blends were performed to assess the impact of the formulation changes upon continuous twin-screw feeding. The transfer of the glidant from extra-granular to intra-granular phase allowed to improve the flowability of the blends. A sufficient feeding capacity for the downstream process and a mitigation of the impact of batch-to-batch variability of the API upon twin-screw feeding of the blends could be achieved. No effect of the formulation or of the API properties on the feeding stability was observed. The material characterization of the blends allowed identifying the material attributes which were critical for continuous twin-screw feeding (i.e., bulk density, mass charge and powder cohesiveness).