Insights into the Moisture Scavenging Properties of Different Types of Starch in Tablets Containing a Moisture-Sensitive Drug

Starch is a commonly used excipient in the pharmaceutical industry. However, information on the effect of the moisture scavenging properties of starch to protect moisture-sensitive drugs is limited. The interaction between starch and moisture is of particular interest as moisture fugacity can impact drug stability. In this study, the moisture behavior of different starches was examined for an understanding of its role in the degradation of acetylsalicylic acid. The starches were characterized for their dimensional- and moisture-related properties. Stability testing was carried out on tablets containing acetylsalicylic acid and different starches. Although moisture sorption processes were visually comparable for the different starches, quantitative differences were found in their moisture interaction and distribution. From the sorption isotherms, moisture monolayer coverage and area of hysteresis were found to correlate well with the percentage of acetylsalicylic acid degradation. The lowest percentage of acetylsalicylic acid degradation was observed in starch that exhibited high monolayer coverage, large area of hysteresis, and good capacity for internally absorbed moisture. Findings from this study highlighted the value of moisture scavenging excipients when formulating moisture-sensitive drug products. Clearly, the assessment of moisture sorption properties of excipients during the preformulation phase can be an invaluable exercise for identifying the best possible ingredients in formulations where moisture sensitivity is an area of concern.

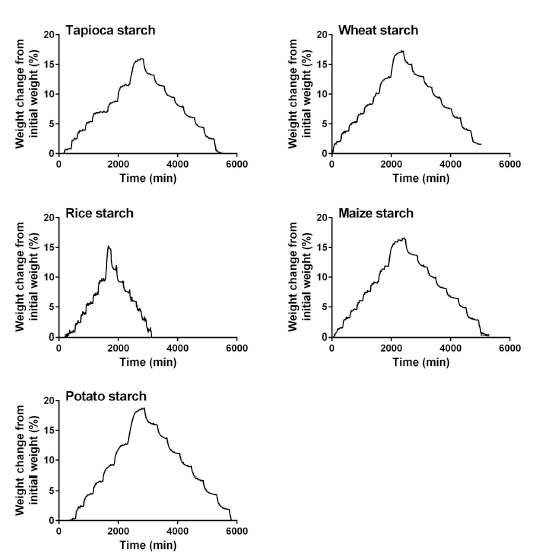

Weight change over time under a given RH condition for different types of starch

Check also: Starch based excipients for pharmaceutical tablets

or this overview by Pharmapproach

Pharmaceutical Applications of Native Starch

Starch as tablet disintegrant

Starch is one of the most commonly used disintegrants for immediate release tablet dosage forms at concentrations of 3–25% w/w (optimum concentration of 15%). The disintegration ability of native starch is due to wicking and restoration of deformed starch particles on contact with aqueous fluid. Some newer sources of starch have been chemically, physically or enzymatically modified to enhance their disintegrant properties e.g. carboxymethyl starch (CMS) which possesses high swelling capacity (absorb an amount of water 23 times its initial weight) combined with a high rate of water permeation.

Starch as diluent/fillers/bulking agent

Starch becomes an integral part of a formula during manufacture when added in the range of 5–80% w/w to achieve standardized triturates of colourants, potent drugs/ low dose Active Pharmaceutical Ingredients (APIs) and herbal extracts thus facilitating effective handling and subsequent mixing/ blending processes during manufacture. This is due to its desirable intrinsic properties such as absence of risky interactions with most common APIs and excipients, absence of physiological and pharmacological activities as well as consistent physicochemical and functional properties.

Starch as glidant

Considering the weight uniformity required by the pharmacopoeias, it thus becomes evident that controlling or enhancing the flow properties of powders/granules through the feed mechanisms using glidants is of paramount importance. Starch has been widely used for this purpose because of its additional use as disintegrant. It reduces inter-particulate friction when used at concentrations of 2–10% w/w to improve powder and granule flow, especially when using dried starches.

Starch as controlled/sustained release polymer for drugs and hormones

Modified starches (e.g., cross-linked high amylose corn starch) have been used as functional ingredients in sustained release formulations to maintain therapeutic concentration of drugs for extended periods of time. They are mainly used as microspheres or hydrogels and their use has been attributed to their improved functionality – its gel-forming ability, biodegradability, and biocompatibility.

Starch as antiadherent and lubricant

Starches are used as antiadherent and lubricant at a concentration of 3–10% w/w during tablets and capsules production. The antiadherent properties of starch prevent the sticking of compressed powders/granules to punch faces and the die wall or in the case of encapsulation, prevents sticking to the powder mix to the dosators and tamping pins of encapsulates. Starch also reduces friction by interposing an intermediate layer between the tablet constituents and the die wall during compression and ejection processes.

Starch as binder

In tablet formulations, starch prepared to gel (freshly prepared starch paste) by heat treatment of the starch dispersion in water is used at a concentration of 3–20% w/w (usually 5–10%, depending on the starch type) as a binder for wet granulation. This provides the necessary binding force that holds the powder particles together to form the required agglomerates. The quantity of the freshly prepared starch paste used should be determined by optimization studies, using parameters such as tablet friability and hardness, disintegration time, and drug dissolution rate. This also serves to ensure a uniform distribution and controllable release of the APIs.

Starch in topical formulations

Starch, particularly the fine powders of rice and wheat starch, is used as a base in topical preparations for its absorbency of liquids. Starch paste is used in ointment formulations, usually in the presence of higher ratios of glycerin.

Starch as a film-forming polymer

The film-forming property of starch can be attributed to the amylose component of starch. Scientific investigations suggest that this property can be improved by combining starch with other polymers such as chitosan, microcrystalline cellulose, flax cellulose nanocrystals etc. A blend of starch and chitosan blend exhibit a good film-forming property which is attributed to hydrogen bond formation between the functional group (amino and hydroxyl groups) present on the backbone of the two component. Edible film is produced by combining cornstarch and microcrystalline cellulose in the absence or presence of plasticizers. Also, starch-based nanocomposite film is obtained from a blend of plasticized starch and flax cellulose nanocrystals. pharmaceutical applications of native starch

Starch in bone tissue engineering (TE)

As an alternative to the use of metals and ceramics in TE, biodegradable polymers such as starch, collagen, fibrinogen, chitosan, hyaluronic acid (HA), poly(hydroxybutyrate), poly(a-hydroxy acids), poly(e-caprolactone), poly(propylene fumarates), poly(carbonates), poly-(phosphazenes) and poly(anhydrides) are believed to be the ideal materials for bone TE. Starch-based biodegradable polymers (SBBP), when used in bone tissue engineering scaffolds, can provide immediate structural support as a result of its good mechanical properties. It also allows for increased degradation time (producing non-toxic degradation products) and consequently expanded porosity as cellular integration increases, which is optimal for bone tissue engineering.

Starch as plasma volume expander

Natural and modified starches are now used in the development and formulation of plasma volume expanders. Examples include acetylated starch (e.g., acetyl starch) and hydroxyethyl starch which are now used to prevent shock following heavy blood loss resulting from surgery, trauma etc.

Starch as adjuncts to standard Oral Rehydration Solution (ORS)

Starch appears to be useful adjuncts to standard ORS in the treatment of cholera/ diarrhoea in children. It promotes fluid and electrolyte absorption and may add additional energy without increasing the osmotic load and also shorten the recovery period from diarrheal disease. A typical example of starch used for this purpose is rice starch. Others include modified tapioca starch and plantain starch.

Starch in artificial red cells

Starch particularly, potato starch has been used to produce artificial red blood cells with good oxygen-carrying capacity. It was prepared by encapsulating haemoglobin (Hb) with long-chain fatty acid grafted potato starch by self-assembly.