Delta-mannitol to enable continuous twin-screw granulation of a highly dosed, poorly compactable formulation

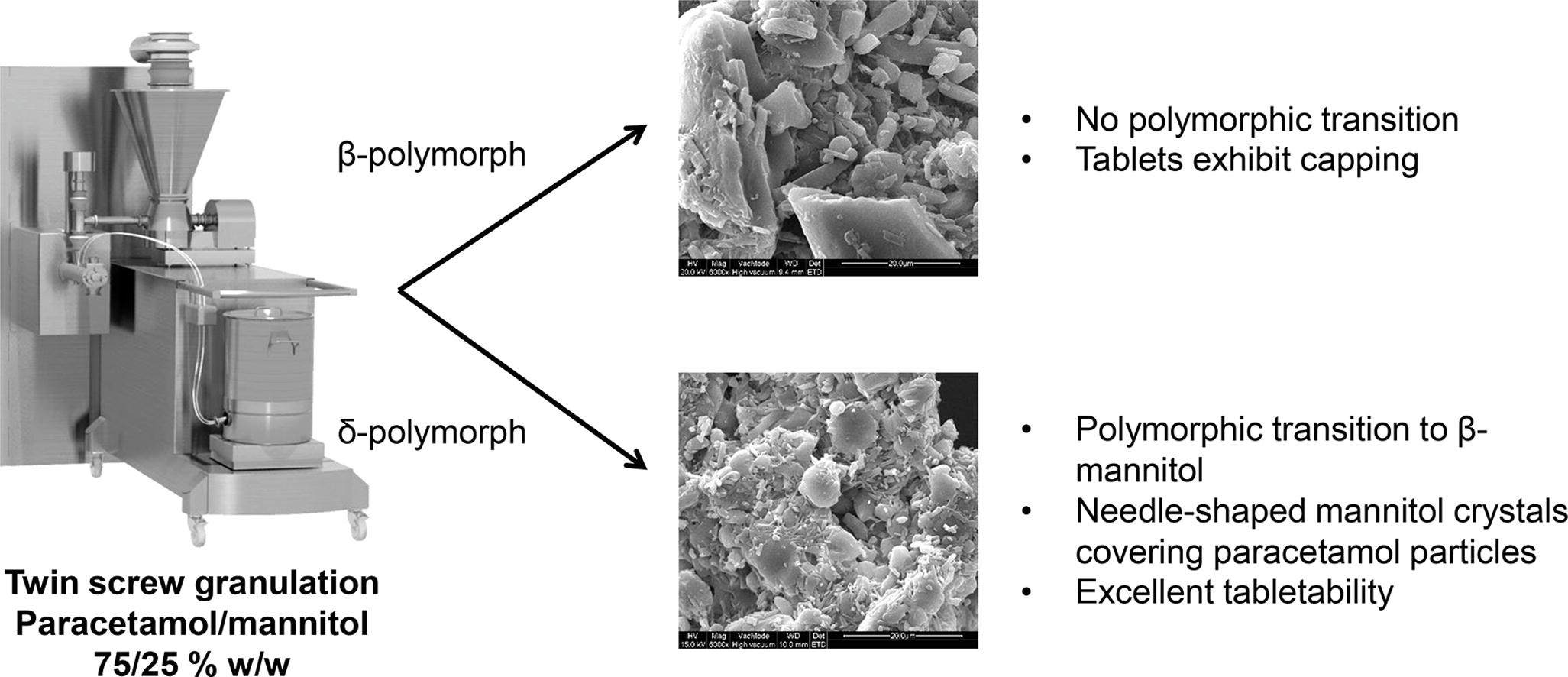

In current study, it was investigated if the moisture-mediated polymorphic transition from δ- to β-mannitol during twin screw granulation (TSG) also took place in high drug loaded formulations and if the specific granule morphology associated with the polymorphic transition could enable tableting of granules comprising 75% paracetamol, a poorly compactable drug.

Experiments were performed on an integrated continuous manufacturing line, including a twin screw granulator, fluid bed dryer, mill and tablet press. The polymorphic transition of δ- to β-mannitol was observed during twin screw granulation and granules exhibited the needle-shaped morphology, typical of this transition. TSG at low liquid-to-solid (L/S) ratios and use of polyvinylpyrrolidone or hydroxypropylmethylcellulose as binders inhibited the polymorphic transition, whereas screw speed, drying time, drying temperature and airflow did not affect the solid state of mannitol in the granules.

Without binder and despite the high paracetamol drug load in the formulation, limited breakage and attrition was observed during drying and milling. In contrast to granules manufactured from a formulation containing paracetamol/β-mannitol which could not be tableted due to extensive capping, granules prepared from a paracetamol/δ-mannitol formulation showed good tabletability. In conclusion, δ-mannitol is a promising TSG excipient, especially for high drug-loaded formulations with poor tabletability. More on continuous twin screw extrusion with delta mannitol

Materials

δ-mannitol (Parteck® Delta M) and β-mannitol (Parteck® M200) were kindly donated by Merck Millipore (Darmstadt, Germany). Paracetamol (powder grade) was purchased from Mallinckrodt (Hazelwood, USA). Polyvinylpyrrolidone (PVP) K30 and hydroxypropylmethylcellulose (HPMC) E5 were kindly donated by BASF (Ludwigshafen, Germany) and Dow (Bomlitz, Germany), respectively. Magnesium stearate (Fagron, Waregem, Belgium) was used as lubricant for tableting.

Conclusions

Similar to twin screw granulation of pure δ-mannitol, the polymorphic transition of δ- to β-mannitol also occurred during granulation of a formulation containing 75% paracetamol, yielding granules with a unique surface morphology. This polymorphic transition was dependent on the L/S ratio: lower L/S ratios resulted in a higher residual δ- mannitol content. Additionally, the polymorphic transition was inhibited by inclusion of HPMC or PVP as binder in the granules. Fluid bed drying resulted in a higher residual δ-mannitol fraction in the granules which was attributed to the faster drying kinetics compared to tray drying. The fluid bed drying parameters (drying temperature, airflow, drying time) and milling did not affect the polymorphic transition. Despite the absence of binder in the formulation, granules exhibited limited breakage and attrition during transfer and fluid bed drying. The milled granules manufactured from the paracetamol/δ-mannitol formulation exhibited excellent tabletability, whereas tableting granules prepared from the paracetamol/β-mannitol formulation was not possible due to extensive capping. This was attributed to the specific granule morphology of former granules, i.e. agglomerated primary paracetamol crystals covered with small needle-shaped β-mannitol crystals. Thus the inclusion of δ-mannitol in the formulation enabled successful tableting of a highly dosed paracetamol formulation (75% w/ w) and showed a higher potential to be used as preferred excipient for TSG.