Residence time distribution modelling and in line monitoring of drug concentration in a tablet press feed frame containing dead zones

The presence of a ‘significant dead zone’ in any continuous manufacturing equipment may affect the product quality and need to be investigated systematically. Dead zone will affect the residence time distribution (RTD) of continuous manufacturing and thus the mixing and product quality.

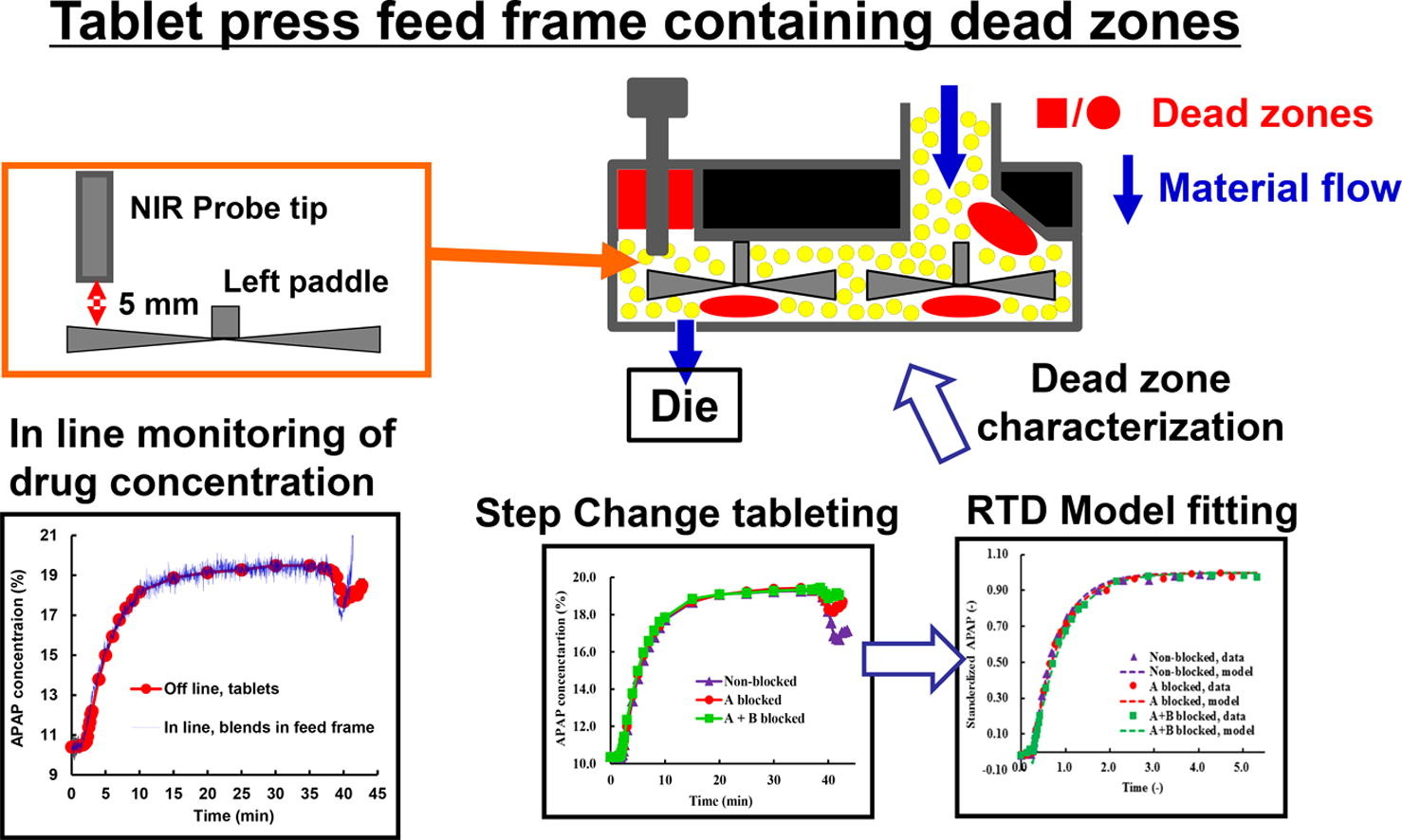

Tablet press (feed frame) is one of unit operations that directly influence the critical quality attributes (CQA’s). However, currently no systematic methods and tools are available to characterize and model the feed frame dead zone. In this manuscript, the RTD of the tablet press feed frame containing dead zone is investigated. Step-change experiments revealed that the feed frame could be expressed as a traditional continuous stirred tank reactor model. The volume fractions of the dead zones are determined experimentally as well as using RTD model. In addition, an in-line NIR method for drug concentration monitoring inside the feed frame is also developed.

The developed NIR calibration model enables to monitor the drug concentration precisely and detect the variation immediately with the probe positioned right above the left paddle. It is also found that the feed frame paddle speed slightly affects the predictive accuracy of NIR, while the die disc speed has no significant effect. Continue on Residence time distribution modelling and in line monitoring of drug concentration in a tablet press feed frame containing dead zones