Formulation development of a continuously manufactured orodispersible film

Continuously manufactured orodispersible films (ODFs) offer a promising approach for individualized therapy with an easy to administer solid dosage form. The aim of this study was to develop a long ODF containing warfarin sodium to enable safe and more flexible dosing. Formulation development was conducted systematically for the continuous film coating process. A continuously working pilot-scale coating bench was used for film manufacturing and the viscosities of the polymer solutions were investigated to obtain processible formulations.

The investigation of the mechanical properties of the long film was an integral part of the study, because the handling of the long film during flexible dosing differs distinctly from the handling of a single dosed ODF. The secant modulus and the yield stress were evaluated as parameters with high information value about the deformation behavior of the ODF.

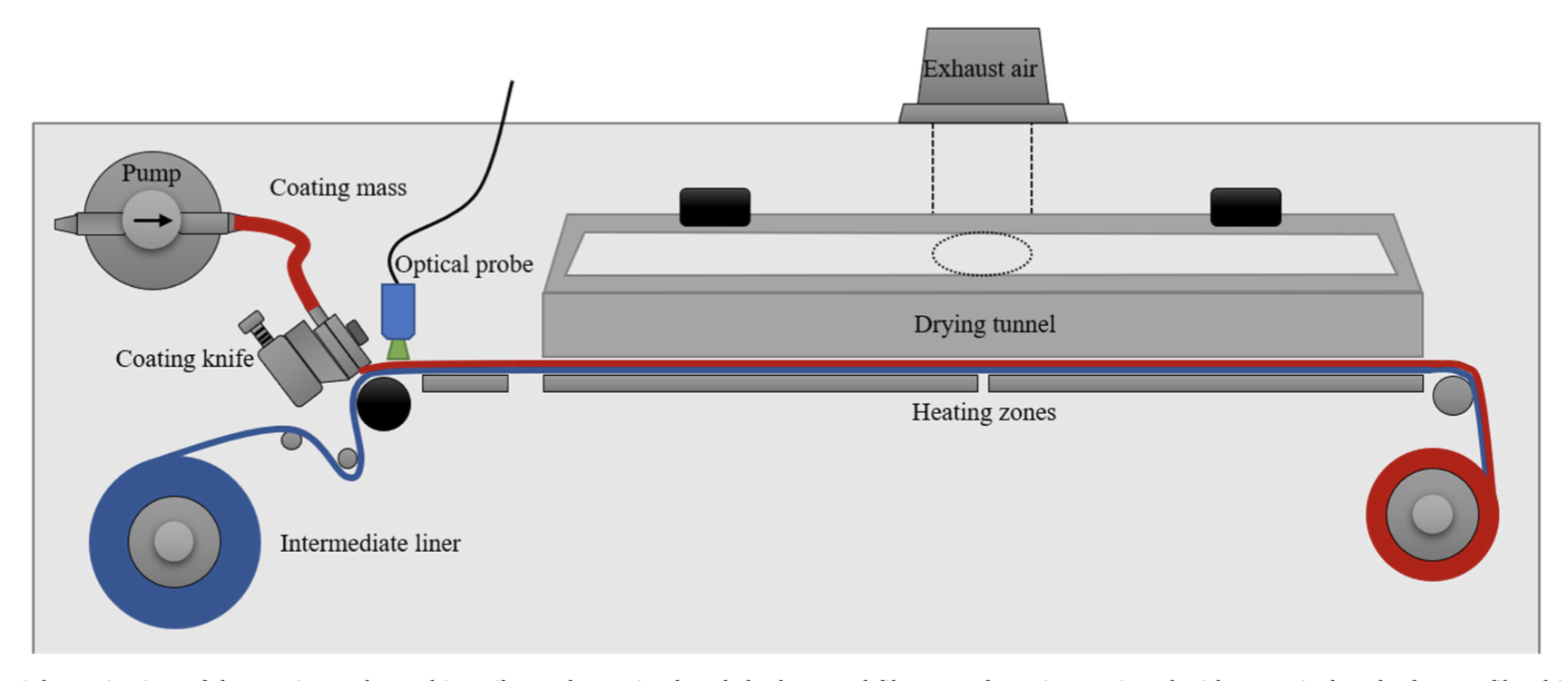

A long warfarin ODF was successfully produced using the pilot-scale coating bench equipped with an optical probe for in-line film thickness measurement. It was feasible to use the principle of a tape dispenser for flexible and, therefore, individualized dosing as proof of concept. Combining the long ODF with a dosing device allows individualized therapy with warfarin for all age groups manageable by the patient himself. Continue on continuously manufactured orodispersible film