Physico-chemical Modification of Gelatine for the Improvement of 3D Printability of Oxidized Alginate-gelatine Hydrogels Towards Cartilage Tissue Engineering

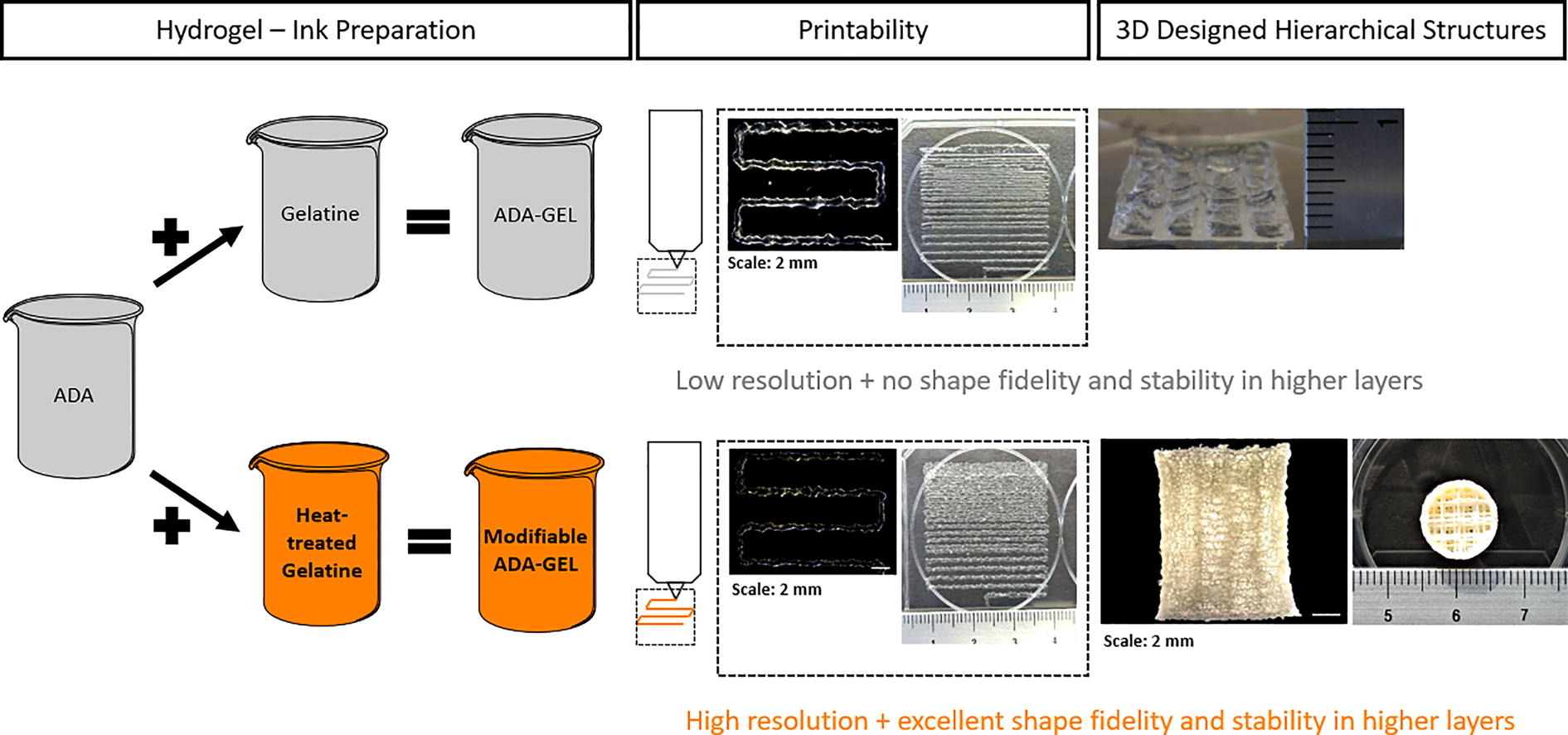

This work explored 3D bioplotting to mimic the intrinsic hierarchical structure of natural articular cartilage. Alginate dialdehyde-gelatine (ADA-GEL) was used as a hydrogel ink to create hierarchically ordered scaffolds. In comparison to previously reported ADA-GEL compositions, we introduce a modified formulation featuring increased amounts of thermally modified gelatine.

Highlights

Bioprinting of alginate dialdehyde-gelatine demonstrated for cartilage tissue engineering.

Thermal pre-treatment of gelatine affects hydrogel mechanical and rheological characteristics.

Thermal pre-treatment of gelatine enables 3D printing of hierarchical complex structures.

Gelatine was degraded by hydrolysis which resulted in tailorable printability characteristics further substantiated by rheological analysis. ADA(3.75%w/v)-GEL(7.5%w/v) with gelatine modified at 80 °C for 3 h could be printed in hierarchical complex structures reaching scaffold heights of over 1 cm. The hierarchical structure of the scaffolds was confirmed via µ-CT analysis. To examine mechanical properties as well as the suitability of the hydrogel as a proper matrix for cell seeding and encapsulation, nanoindentation was performed. Elastic moduli in the range of ∼ 5 kPa were measured. Gelatine heat pre-treatment resulted in modifiable mechanical and rheological characteristics of ADA-GEL.

In summary, this study demonstrates the possibility to enhance the printability of ADA-GEL hydrogels to fabricate hierarchical scaffold structures with shape stability and fidelity, without the necessity to change the initial hydrogel chemistry by the use of additives or crosslinkers, providing a valuable approach for fabrication of designed scaffolds for cartilage tissue engineering.

Download the full article as a PDF here or read it here

Materials: Covalently crosslinked ADA-GEL hydrogel was synthesised as described by Sarker et al [20]. Briefly, ADA (alginate-di-aldehyde) was prepared by the oxidation of alginate (VIVAPHARM® alginate, PH176, from brown algae, pharmaceutical excipient grade, JRS PHARMA GmbH & Co. KG, Germany) using sodium (meta)periodate (NaIO4, Sigma-Aldrich, Germany) as an oxidising agent in an ethanol-ultrapure water mixture (1:1). The suspension was stirred for 6 h at 22 °C (room temperature, RT) under the complete absence of light. The oxidation reaction was quenched by adding ethylene-glycol (VWR Chemicals International) and stirred for additional 30 minutes. The resultant suspension was transferred into several dialysis molecular porous membrane tubes (MWCO: 6-8 kDa, Spectrum Laboratories, USA) and dialysed against ultrapure water (UPW, Milli-Q®, Merck Millipore, Germany). UPW was changed twice a day during five days of dialysis. After dialysis, the ADA product was frozen for at least 48 hours before it was transferred into the freeze dryer (ALPHA 1-2 LDplus, CHRIST Gefriertrocknungsanlagen, Germany) for lyophilisation.

Article information: T. Kreller, T. Distler, S. Heid, S. Gerth, R. Detsch, A.R. Boccaccini, Physico-chemical Modification of Gelatine for the Improvement of 3D Printability of Oxidized Alginate-gelatine Hydrogels Towards Cartilage Tissue Engineering, Materials & Design, 2021. https://doi.org/10.1016/j.matdes.2021.109877.