A novel approach to minimize loss of compactibility in a dry granulation process using superdisintegrants

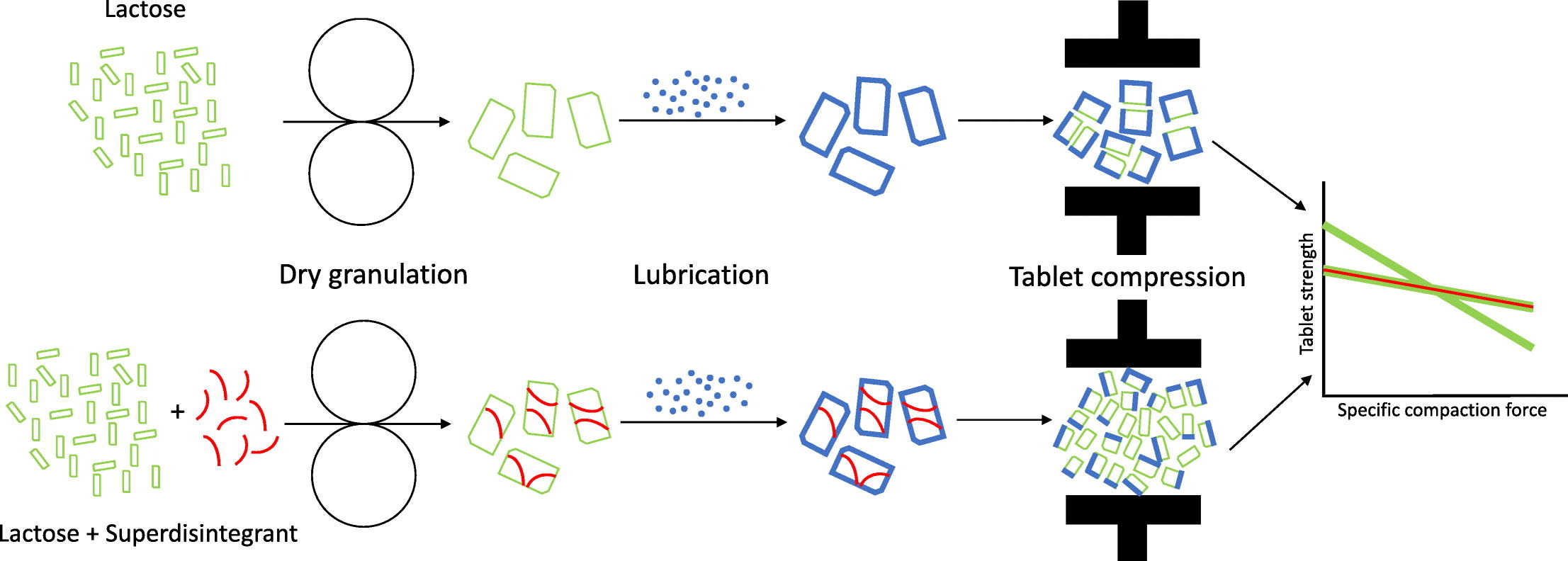

Dry granulation via roller compaction is increasingly being used as granulation method for the production of oral solid dosage forms. Advantages of roller compaction include a simplified process compared to wet granulation and the inherently continuous nature of the process. A common problem of dry granulation, however, is the loss of compactibility of the granules compared to the ungranulated powders. Here we show a novel approach to minimize the loss of compactibility during dry granulation. The intra-granular addition of superdisintegrant reduces the loss of compactibility of anhydrous lactose-based granules produced via roller compaction.

Highlights

- • Superdisintegrants can reduce loss of compactibility in dry granulation.

- • Intra-granular superdisintegrant promotes granule fragmentation during tableting.

- • Granule hardening reduces the compactibility of anhydrous lactose.

- • Superdisintegrants can be used to reduce the granule hardening effect.

- • Superdisintegrant performance is not affected by dry granulation.

This effect is explained by a reduced hardness of the granules, which promotes granule fragmentation upon tablet compression. This higher degree of fragmentation increases the lactose surface available for bonding, thereby improving tablet strength. The results presented here show how intra-granular superdisintegrants can be used to minimize the loss of compactibility of a dry granulation formulation.

Download the research paper as PDF: A novel approach to minimize loss of compactibility in a dry granulation process using superdisintegrants

Materials

Anhydrous lactose (SuperTab® 21AN), croscarmellose sodium (Primellose®) and sodium starch glycolate (Primojel®) were obtained from DFE Pharma (Goch, Germany). The anhydrous lactose used in this study predominantly consists of ẞ-lactose (84% w/w) with a smaller fraction of α-lactose (16% w/w), as measured by gas chromatography according to the European Pharmacopoeia. Magnesium stearate (technical grade) was purchased from Sigma-Aldrich (St. Louis, USA) and was used as received.

Maarten Jaspers, Timo P. Roelofs, Pauline H.M. Janssen, Robin Meier, Bastiaan H.J. Dickhoff,

A novel approach to minimize loss of compactibility in a dry granulation process using superdisintegrants,

Powder Technology, 2022, 117773, ISSN 0032-5910,

https://doi.org/10.1016/j.powtec.2022.117773.