FlowLac® – MEGGLE’s spray-dried lactose grades for direct compression

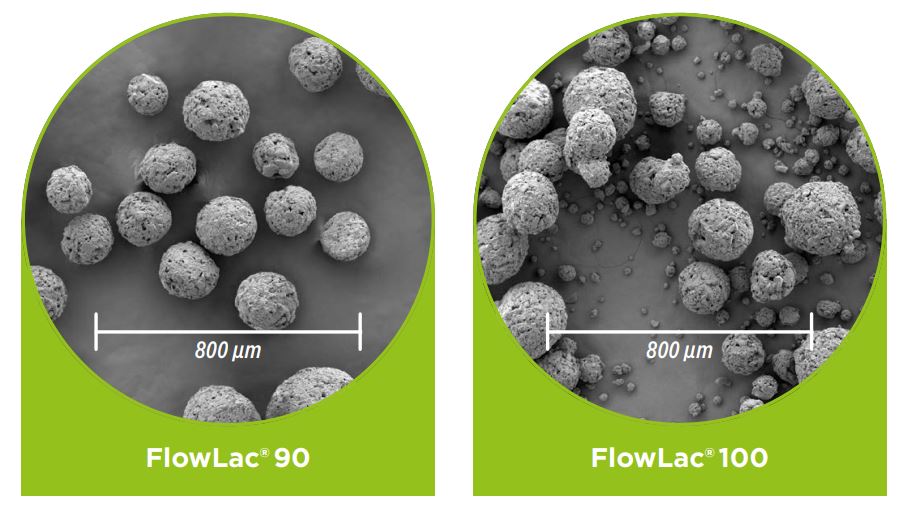

FlowLac by MEGGLE is directly compressible lactose having a spherical agglomerate shape, consisting of small alpha-lactose monohydrate crystals bound by amorphous lactose. It is produced by spray-drying a suspension of fine milled alpha-lactose monohydrate crystals in a solution of lactose. When lactose in solution is spray-dried, a rapid removal of water is taking place, whereby amorphous, non-crystalline lactose is formed in addition to crystalline lactose. Based on the amorphous content, kept on a stable level, non-varying better tabletting properties can be reached.

General information

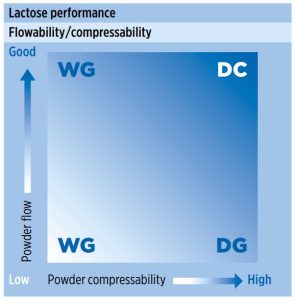

Direct compression (DC) tablet manufacture is a popular choice because it provides the least complex, most cost effective process to produce tablets compared to other tablet manufacturing approaches. Manufacturers can blend APIs with excipients and compress, making dosage forms simple to produce [1, 2].

DC technology and the use of modern tableting equipment require that excipients and APIs form a compactable mixture with excellent flowability and low particle segregation tendency [3].

In the pharmaceutical industry, lactose is one of the most commonly used excipients; however, like many other excipients, lactose may not be suitable for direct compression without modification due to insufficient powder flow or/and compaction properties (figure 1).

In the early 1960’s, the introduction of spray-dried lactose changed tablet manufacturing processes and increased direct compression tableting possibilities [4]. Today, MEGGLE is a leading spray-dried lactose manufacturer with the FlowLac® brand.

Product description

FlowLac® is produced by spray-drying a fine milled alpha-lactose monohydrate suspension. When lactose is spray-dried, the rapid water evaporation causes amorphous lactose to form [5]. Most commercially available, spray-dried lactose products contain 10 to 15 % amorphous lactose at the time of manufacture, depending on the solids content and process conditions.

Compared to crystalline alpha-lactose monohydrate, FlowLac®’s compactibility is superior. Unlike alpha-lactose monohydrate and anhydrous beta-lactose, which are known to exhibit brittle fracture during compaction, amorphous lactose plastically deforms. Therefore, due to the synergistic plastic and brittle nature of amorphous and crystalline forms in spray-dried lactose, the result is superior compactibility [6].

FlowLac® 100 is the standard grade for spray-dried lactose, providing excellent flowability and extraordinary compactibility compared to other lactose grades. FlowLac® 90 was developed to provide greater compactibility compared to FlowLac® 100 by optimizing the amorphous lactose content. In addition, the particle size distribution makes FlowLac® 90 virtually dust-free.

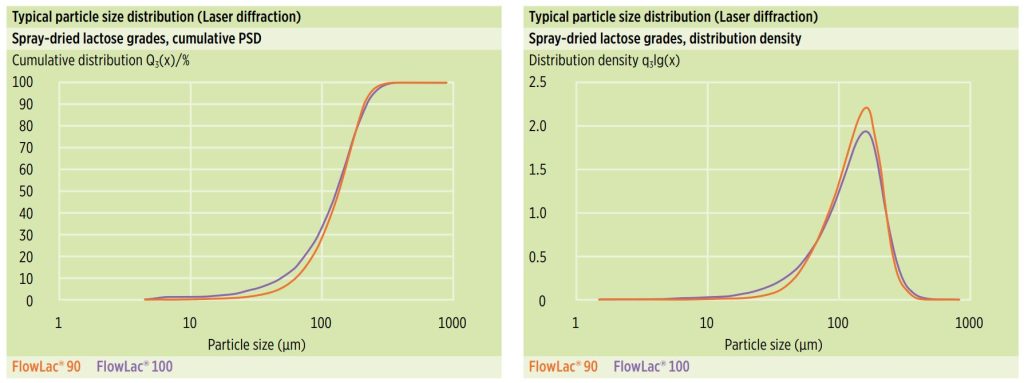

Particle size distribution (PSD)

Figure 2 shows typical PSD data by laser diffraction for MEGGLE’s spray-dried lactose grades, FlowLac®. FlowLac® 90 offers a narrower particle size distribution than FlowLac® 100 because of its reduced fines content.

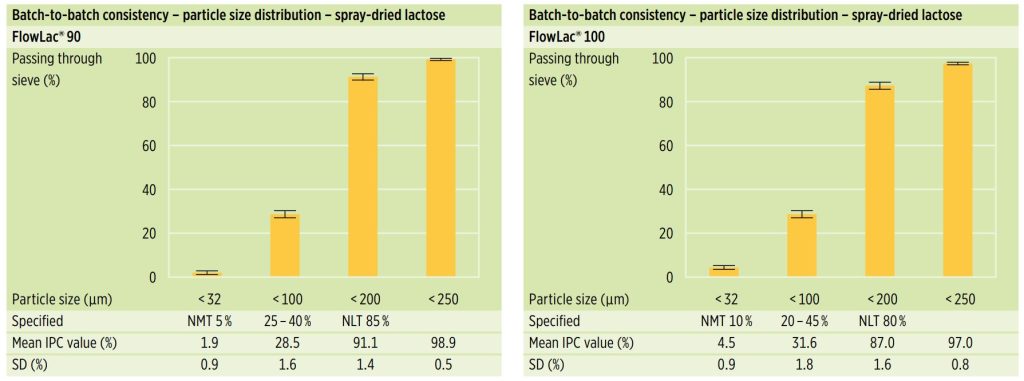

Figure 3 depicts typical the specified PSD data by air-jet sieving. These parameters are specified and are part of in-process control (IPC).

Batch-to-batch consistency

Batch-to-batch consistency for all lactose products can be attributed to MEGGLE’s long history and experience in lactose manufacture, and broad technical expertise. Constant in-process and final product testing ensures consistency and quality (figure 4).

See the full brochure on “FlowLac®” here

(click the picture to download the brochure)

Benefits FlowLac®

- Superior flowability

- Excellent compactibility

- Low hygroscopicity and high stability

Source: MEGGLE brochure “FlowLac®”

See the overview video of the MEGGLE Dry Powder Inhalation product range here:

Company: MEGGLE is one of the world´s leading manufacturers of pharmaceutical grade lactose and co-processed excipients with expertise of more than 70 years. We encounter lactose in so many areas of our life – reason enough to take a closer look at this multi-functional “white powder”.

Do you need more information or a sample of FlowLac® excipients?