Investigating the influence of various plasticiser on the properties of Kollicoat® SR 30 D based coats

INTRODUCTION

Plasticiser play a decisive role in the application of functional films, especially, if an aqueous dispersion containing a water insoluble polymer is used. For the water insoluble sustained release film forming polymer PVAc, both elongation at break and minimum film forming temperature (MFFT) depend strongly on the type and amount of plasticiser used in the coating formulation. As MFFT is comparably low for PVAc (18°C) this physical characteristic is of minor interest [1]. However, the elongation properties are of huge importance, especially if coated particles are compressed to multiple unit pellet systems (MUPS). This investigation is intended to consider the suitability of three different plasticiser: poly(ethylene glycol) 6000, 1,2-propylene glycol and triethyl citrate.

MATERIALS AND METHODS

Materials:

Poly(vinyl acetate) (Kollicoat® SR 30 D, BASF SE, Germany) was used in combination with the following plasticisers:

- a) Poly(ethylene glycol) (PEG) 6000 (Lutrol® E 6000, BASF)

- b) 1,2-Propylene glycol (PG) (Propylene glycol pharma, BASF)

- c) Triethyl citrate (TEC) (Merck)

Formulations

The isolated films were prepared with a plasticiser content of 10% (m/m) each, calculated on the polymer content of the dispersion. To assure homogeneously distribution and incorporation within the PVAc dispersion, the mixture was stirred for at least 2 hours.

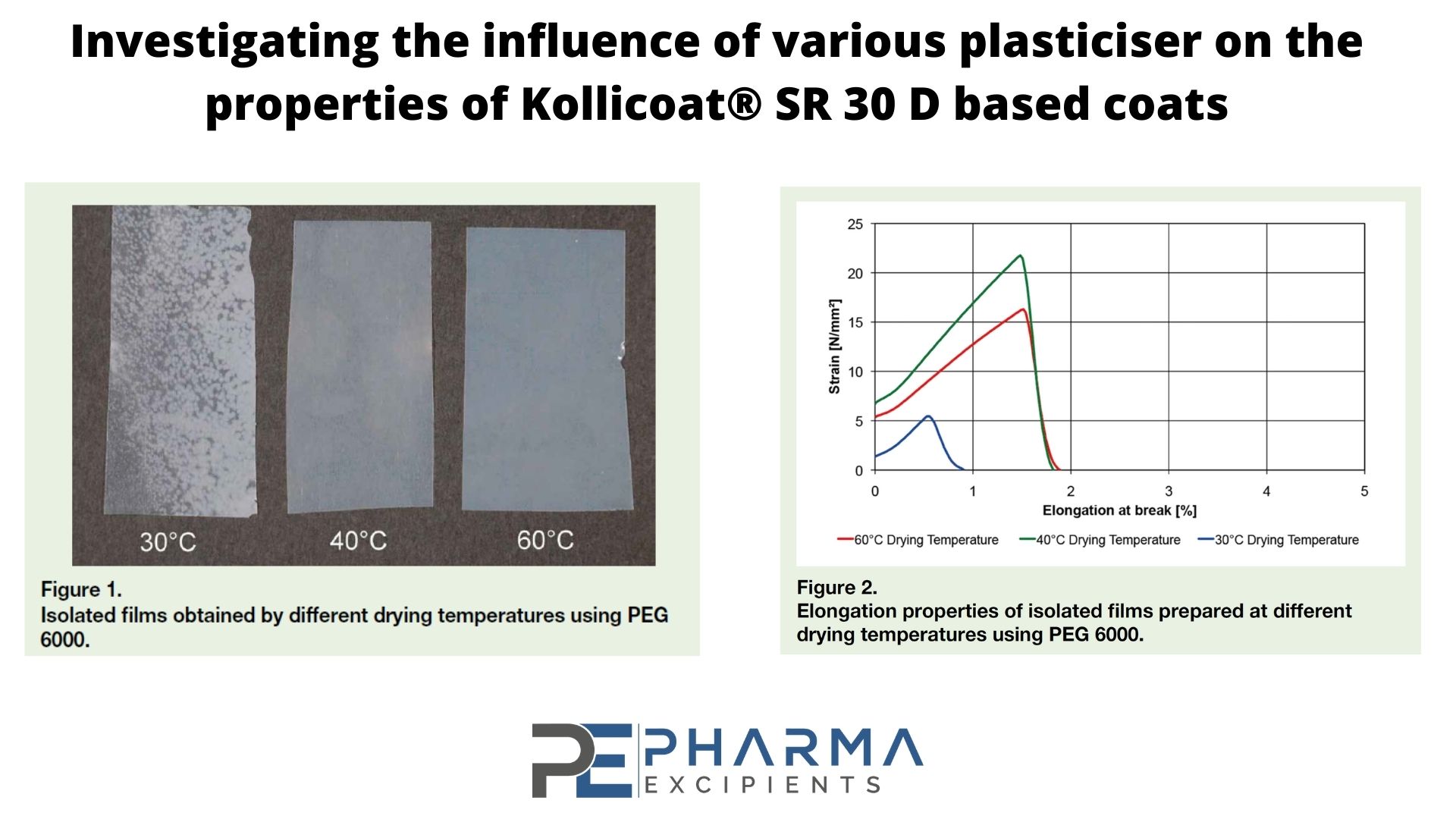

Preparation of isolated films

Isolated films were prepared by using a film caster (Coatmaster, Erichsen Testing Equipment) equipped with a 300 μm knife. The film caster allowed various temperatures to dry the cast films.

Characterisation of isolated films

The film was examined visually as first indication for its quality. To determine the mechanical properties, a texture analyser (TA-XT2i HR, Stable Micro Systems) was used. The testing was performed under climatic controlled conditions of 23°C and 54% r.h. [2]