Kollicoat® Smartseal combines an effective taste-masking functionality with efficient processing

Kollicoat® Smartseal 30 D and Kollicoat® Smartseal 100 P can help formulators tackle challenges when handling bitter active ingredients. It offers superior protection from unpleasant drug taste for minitablets, pellets, particles, and granules used in orally disintegrating dosage forms, improving patient compliance and convenience.

As a more hydrophobic polymer, it requires less film to achieve the desired functionality, streamlining and accelerating coating processes.

The best of both worlds

Bitter and moisture-sensitive active ingredients can pose quite a challenge to formulators – but not anymore. Either of the two desired effects, concealing unpleasant tastes and creating a moisture barrier, can be achieved with a functional film-forming polymer. Kollicoat® Smartseal is highly impermeable to water vapor, helping preserve the potency of sensitive active ingredients. What’s more, the polymer is insoluble in saliva and immediately dissolves in gastric juice. This ensures effective protection from unpleasant tastes in the patient’s mouth and rapid release and onset of action of active ingredients in the stomach.

Available as an aqueous dispersion and a spray dried powder, respectively Kollicoat® Smartseal 30 D and Kollicoat® Smartseal 100 P are easy to handle and to apply. And since they can be used in highly concentrated coating suspensions and at high spray rates, you benefit from reduced process times – and significant cost savings.

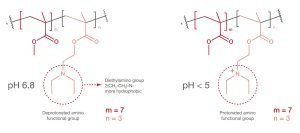

Chemical structure

Kollicoat® Smartseal is a copolymer comprising methyl-methacrylate (MMA) and diethylaminoethyl methacrylate (DEAEMA). It also contains macrogol cetostearylether and sodium lauryl sulfate as stabilizers.

Copolymer of methyl-methacrylate diethylaminoethyl methacrylate (7:3)

Functionality

Kollicoat® Smartseal does not dissolve in the saliva pH due to the basic amino functional group and is promptly soluble in the acid-stomach pH (in both fed and fast conditions) because of the amino group protonation. In addition, Kollicoat® Smartseal has a hydrophobic nature provided by the diethylamino group, which offers an effective moisture barrier besides the superior taste-masking effectiveness.

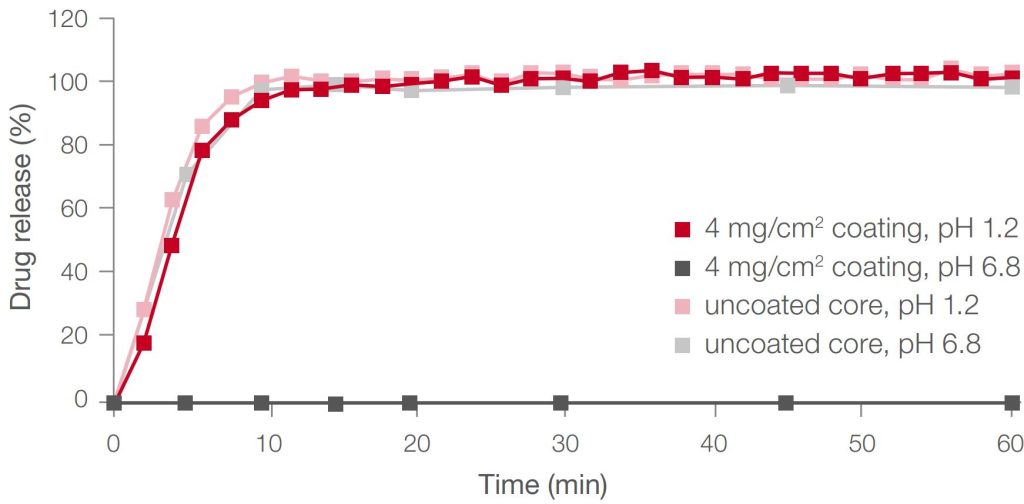

Immediate release of active ingredients in the stomach

Results from dissolution tests demonstrate resistance in neutral saliva and rapid release of the active ingredient in the acidic environment of the stomach.

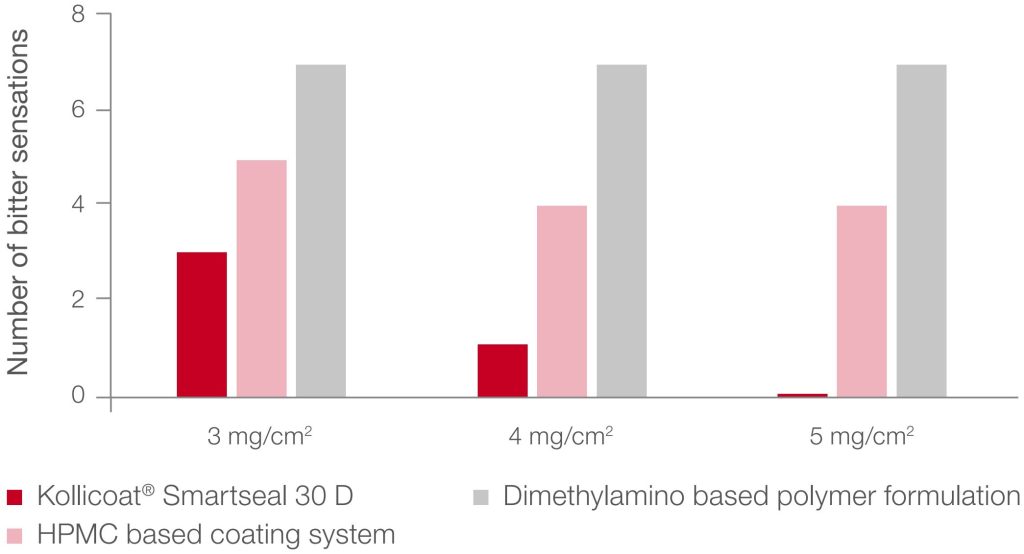

Smart protection from unpleasant taste

Kollicoat® Smartseal hides bitter taste with a significantly reduced coating thickness.

For example, it masks the taste of quinine hydrochloride tablets more effectively than other leading protective coatings.

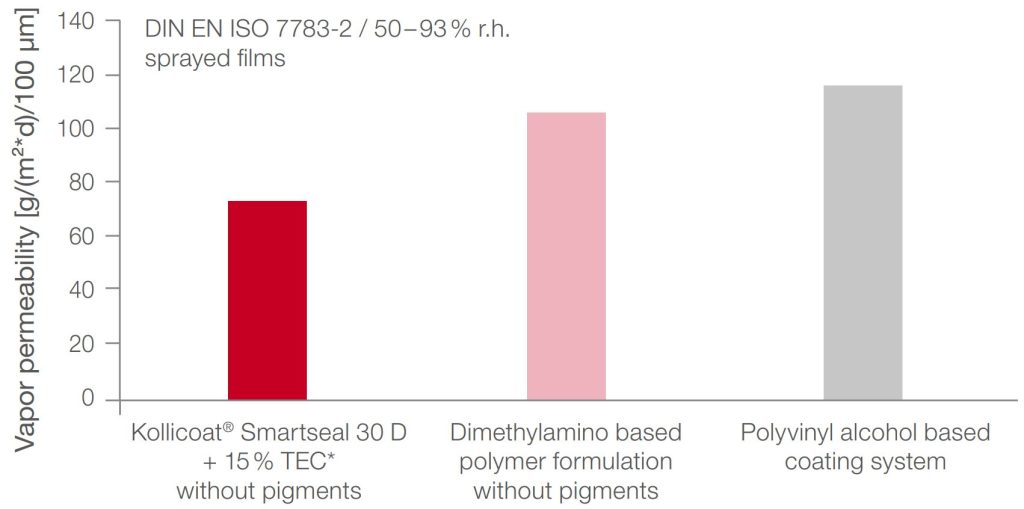

Effective sealing against moisture

Film coatings with a low water vapor permeability can delay the moisture uptake of sensitive cores.

Tests on isolated films show that Kollicoat® Smartseal has a lower water vapor permeability than other leading protective coatings.

See the full brochure on “Kollicoat® Smartseal” here

See the full brochure on “Kollicoat® Smartseal” here

(click the picture to download the poster)

Source: BASF brochure “Kollicoat® Smartseal”

Do you need more information or a sample of excipients by BASF?

Read also the further Kollicoat® Smartseal article: