Comparing Different Moisture Protective Instant Release Coatings for Solid Oral Dosage Forms

Introduction: Drug stability and shelf life are main targets of current pharmaceutical development as many active ingredients are highly moisture sensitive. Instead of using impermeable and expensive packaging materials it appears advisable to test moisture protective instant release film coatings.

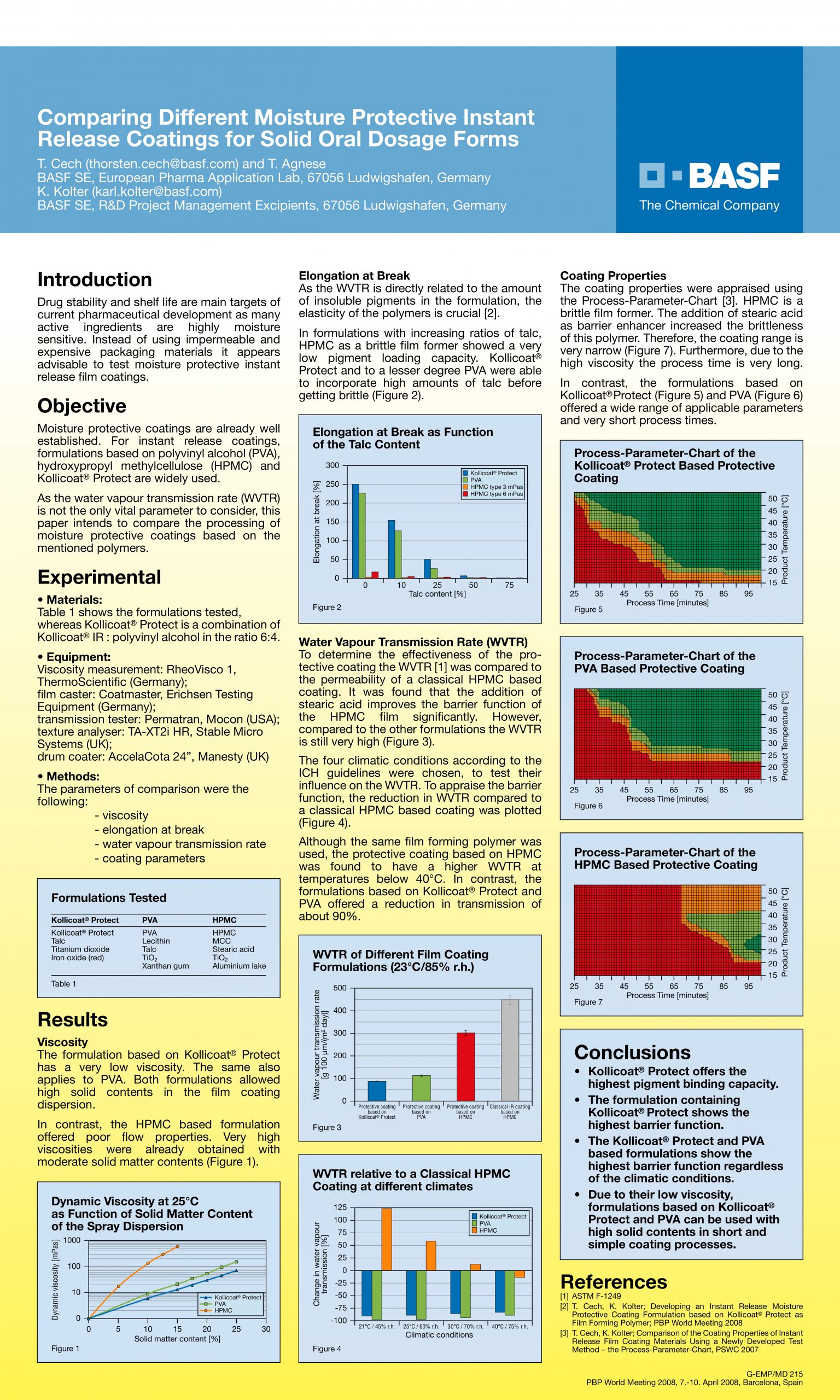

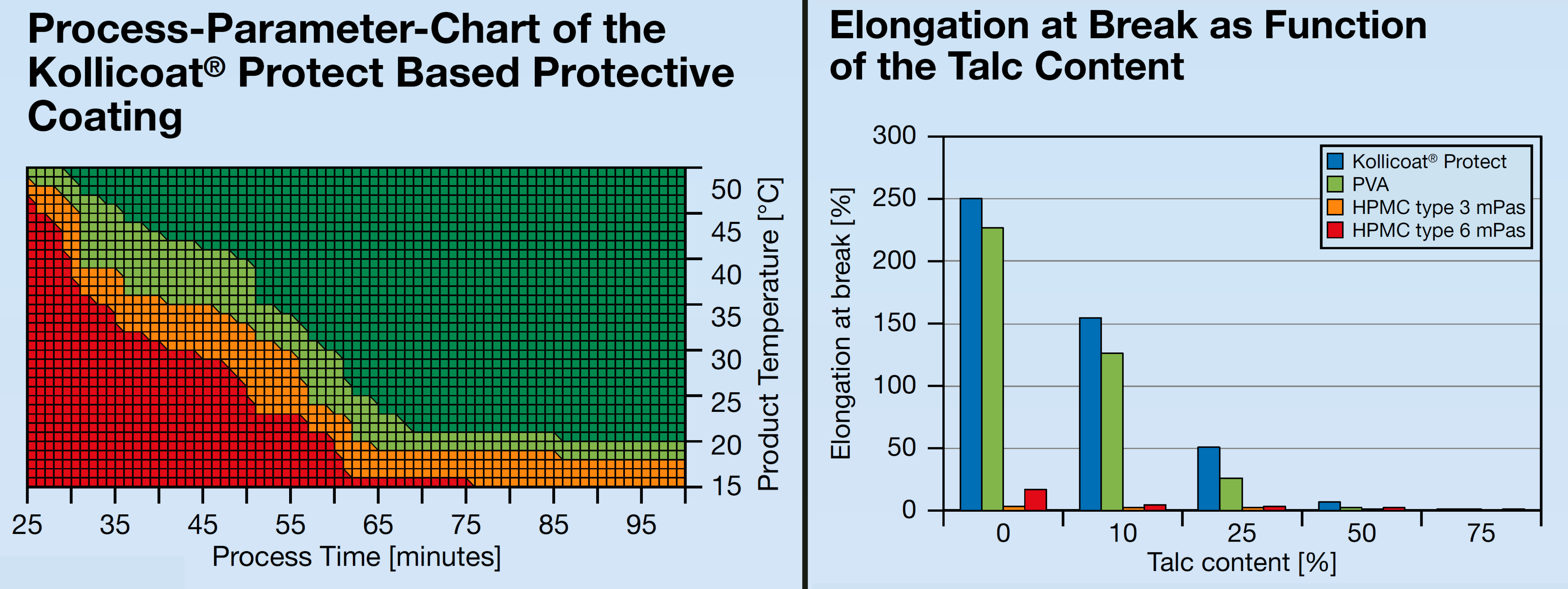

Objective: Moisture protective coatings are already well established. For instant release coatings, formulations based on polyvinyl alcohol (PVA), hydroxypropyl methylcellulose (HPMC) and Kollicoat® Protect are widely used. As the water vapour transmission rate (WVTR) is not the only vital parameter to consider, this paper intends to compare the processing of moisture protective coatings based on the mentioned polymers.

Download the poster as a PDF here

Conclusions

- Kollicoat® Protect offers the highest pigment binding capacity.

- The formulation containing Kollicoat® Protect shows the highest barrier function.

- The Kollicoat® Protect and PVA based formulations show the highest barrier function regardless of the climatic conditions.

- Due to their low viscosity, formulations based on Kollicoat® Protect and PVA can be used with high solid contents in short and simple coating processes.

Authors: T. Cech, T. Agnese, K. Kolter.

Materials: Table 1 shows the formulations tested, whereas Kollicoat® Protect is a combination of Kollicoat® IR : polyvinyl alcohol in the ratio 6:4.