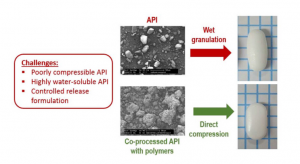

Novel Co-processing Methodology to Enable Direct Compression of a Poorly Compressible Highly Water-Soluble API for Controlled Release

13. September 2018

Herein we introduce an innovative process for preparation of directly compressible API and excipient agglomerates for extended release formulation of a highly water soluble drug, demonstrated with metformin HCl. Metformin is poorly compressible and currently employs wet granulation for tablet manufacturing, resulting in long cycle times. We have co-processed metformin HCl with hydroxypropylmethylcellulose (HPMC) and sodium carboxymethlycellulose (NaCMC) in solvent medium to generate agglomerates which were tableted via direct compression, thereby reducing the drug product manufacturing cycle time and cost, while maintaining extended release dissolution profile. The intimate mixing of HPMC and NaCMC with metformin HCl through co-processing reduces the risk of segregation during downstream handling and tableting. Additionally, this process reduced the excipient load required to achieve the target dissolution profile and bioequivalence, leading to reduced tablet mass and size with 1000 mg drug load.