Influence of material properties and equipment configuration on loss-in-weight feeder performance for drug product continuous manufacture

A programme of work on continuous tablet manufacturing was completed as part of a UK based collaborative research project (REMEDIES: RE-configuring MEDIcines End-to-end Supply) to evaluate the operating space of the continuous platform with respect to material properties. Loss-in-weight (LIW) feeders are extensively used in the Continuous manufacture (CM) to deliver materials into the down-stream unit operations; therefore, control of mass-flow rate is critical for meeting drug product critical quality attributes (CQAs).

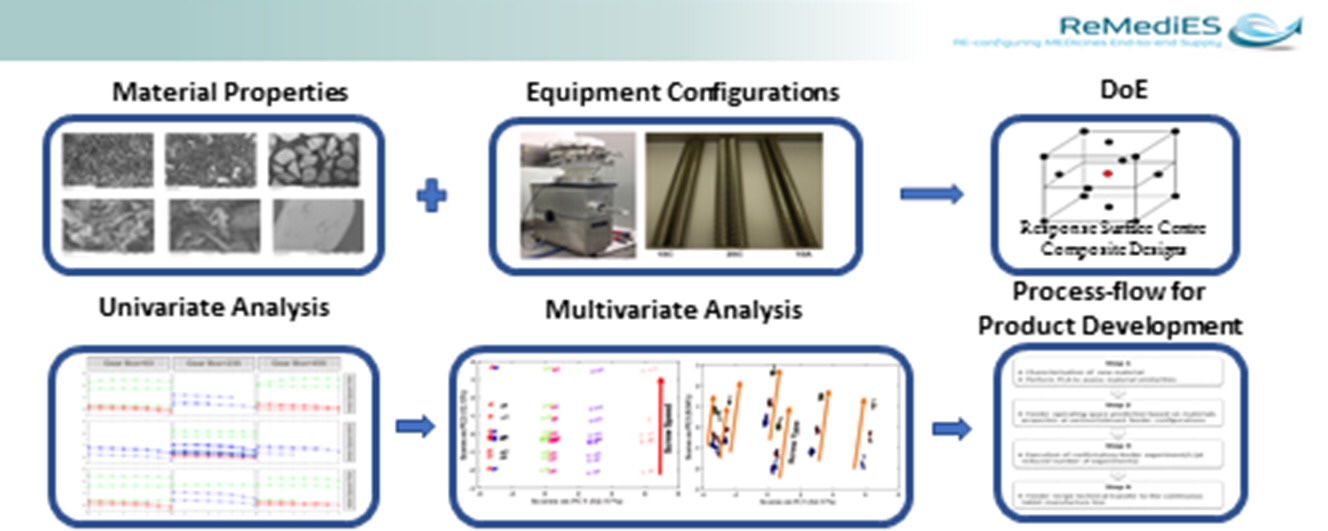

The purpose of this work was to investigate statistical relationship for feeding unit operation that can be applied to new materials such that feeder configuration can be selected based on material properties, reducing the need for material intensive feeder trials. Three different particle size grades of Acetaminophen (APAP) and other typical tablet formulation excipients with divergent material properties were used to evaluate the operating space of the Compact LIW Feeder (GEA) using design of experiments. The presented results showed significant correlation between material properties, feeder configuration, process parameters and feeder operating space using Multivariate Analysis (MVA). The outcome of this study and proposed product development approach has the potential to reduce consumption of material, particularly Active Pharmaceutical Ingredients (APIs), and accelerate product and process development. More on powder feed in continuous manufacturing