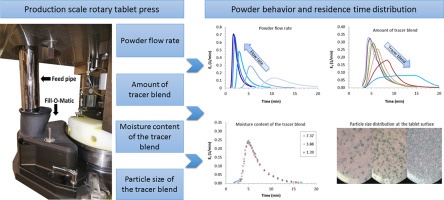

Analysis of the powder behavior and the residence time distribution within a production scale rotary tablet press

This study focuses on the behavior of powder particles in a rotary tablet press with special focus on the feed frame system. To obtain a better knowledge of the continuous manufacturing of tablets, the experimental setup was carried out with a production scale rotary tablet press. The behavior of the powder particles at different flow rates through the tablet press, residual moisture contents, particle sizes, and amounts of tracer was investigated. The residence time distribution was evaluated using the tracer indigo carmine, which was sprayed onto microcrystalline cellulose particle as solution with fluidized bed spray granulator to obtain a tracer blend. The residence time distribution was increased by increasing the amount of tracer blend, and a transition from a plain MCC blend to the tracer blend with regard to continuous manufacturing was shown. Furthermore, it was found that an increase in the flow rates of the powder particles through the tablet press led to a decrease of the residence time distribution (Et). The variation of the flow rate had no influence on the mechanically applied strain at high throughputs, which was confirmed by a constant number of paddle passes (Npp). At the lowest flow rate, the Npp appears to be higher than the constant Npp values at higher flow rates. The residual moisture content did not shown any significant influence on the residence time distribution. The examination of the effect of different tracer blend particle sizes led to an interesting result: It was shown that the particle size segregation only had a low influence on Et. However, a comparably higher influence of the particle size segregation on the particle distribution in the produced tablets was demonstrated. Large particles were deposited at the top of the tablet surface whereas small particles were deposited at their bottom.