Novel cellulose-gelatin composite films made from self-dispersed microgels: Structure and properties

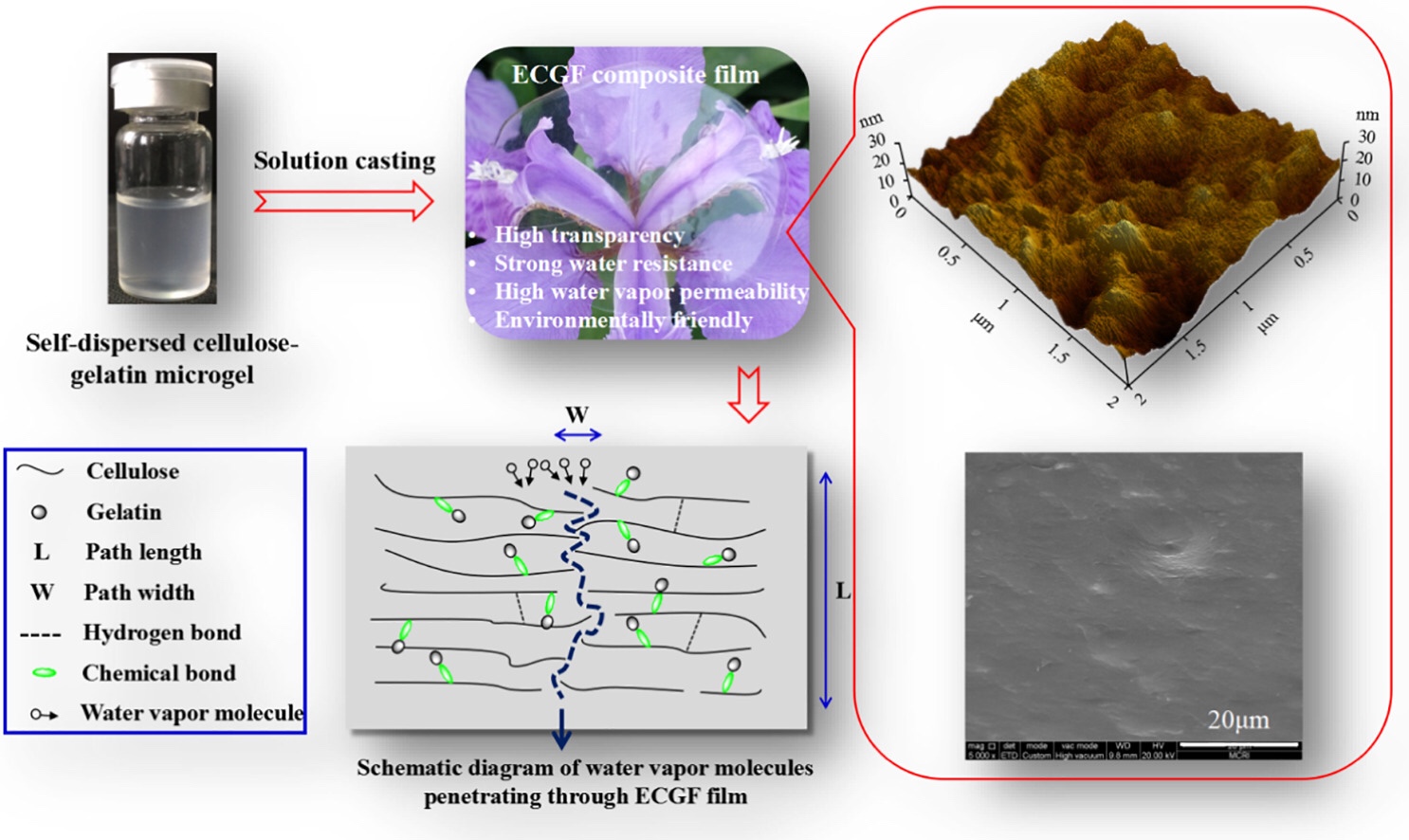

A series of epichlorohydrin-couple-linked cellulose-gelatin composite films (ECGF) was fabricated in NaOH/urea aqueous solution using a process involving homogenous blending, coupling, dialysis, self-dispersion, microgel solution casting, and evaporation. Their structure and properties were characterized with elemental analysis, Fourier transform infrared spectroscopy (FTIR), proton nuclear magnetic resonance (1H NMR), gel permeation chromatography (GPC), scanning electron microscope (SEM), atomic force microscopy (AFM), ultraviolet–visible (UV–vis) spectroscopy, water vapor permeability, and mechanical testing. The results showed that the self-dispersed cellulose-gelatin microgels were successfully prepared and the coupling interactions existed in the inter- and intra-molecules of the corresponding composite films during the fabrication process. The water vapor permeability of the ECGF films was improved when the protein content was higher than 30 wt% in composite films at 75% relative humidity. Interestingly, compared with the cellulose/protein composite films prepared via phase separation method, ECGF films exhibited more homogeneous surface and compact cross-section structures, as well as presented higher light transmittance at 400 nm of about 88% and relative lower swelling ratio. Moreover, ECGF films displayed higher tensile strength compared with that of water-soluble cellulose derivatives/protein composite films in dry and wet states.