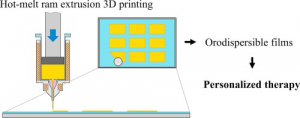

Personalized orodispersible films by hot melt ram extrusion 3D printing

13. September 2018

This work demonstrates the feasibility of the extemporaneous preparation of maltodextrins orodispersible films (ODF) by hot-melt ram-extrusion 3D printing. This method consists of three simple technological operations which can be also implemented in a pharmacy setting. First, maltodextrins, drug, and other excipients are mixed in a mortar and wetted with the plasticizer (i.e. glycerine). Then, the mixture is fed in the chamber of the ram-extruder and heated. ODF are individually printed on the packaging material foil and sealed without further manipulations.

The critical formulation attributes and process variables were investigated to define the processability space. In particular, the optimal conditions to print a mixture of maltodextrins/glycerine in a 80/20 w/w ratio resulted: heating temperature: 85 °C; needle gauge: 18 G; needle-packaging material foil distance: 0.6 mm; maximum print rate: 50 mm/s; filling angle: 120°. The maximum drug loading was about 40%, when paracetamol was used as model drug. The compounded ODF complied with USP and Ph. Eur. specifications for disintegration time (<1 min). The dissolution pattern of paracetamol overlapped with that obtained from ODF with a similar composition prepared by the consolidated solvent casting technique, demonstrating the suitability of the proposed technology.