A contact model for the deformation behaviour of pharmaceutical pellets under cyclic loading

Spherical pharmaceutical pellets are commonly produced by an extrusion-spheronization process. In the spheronizer, the wet cylindrical extrudates are rounded into spheres due to multiple collisions.

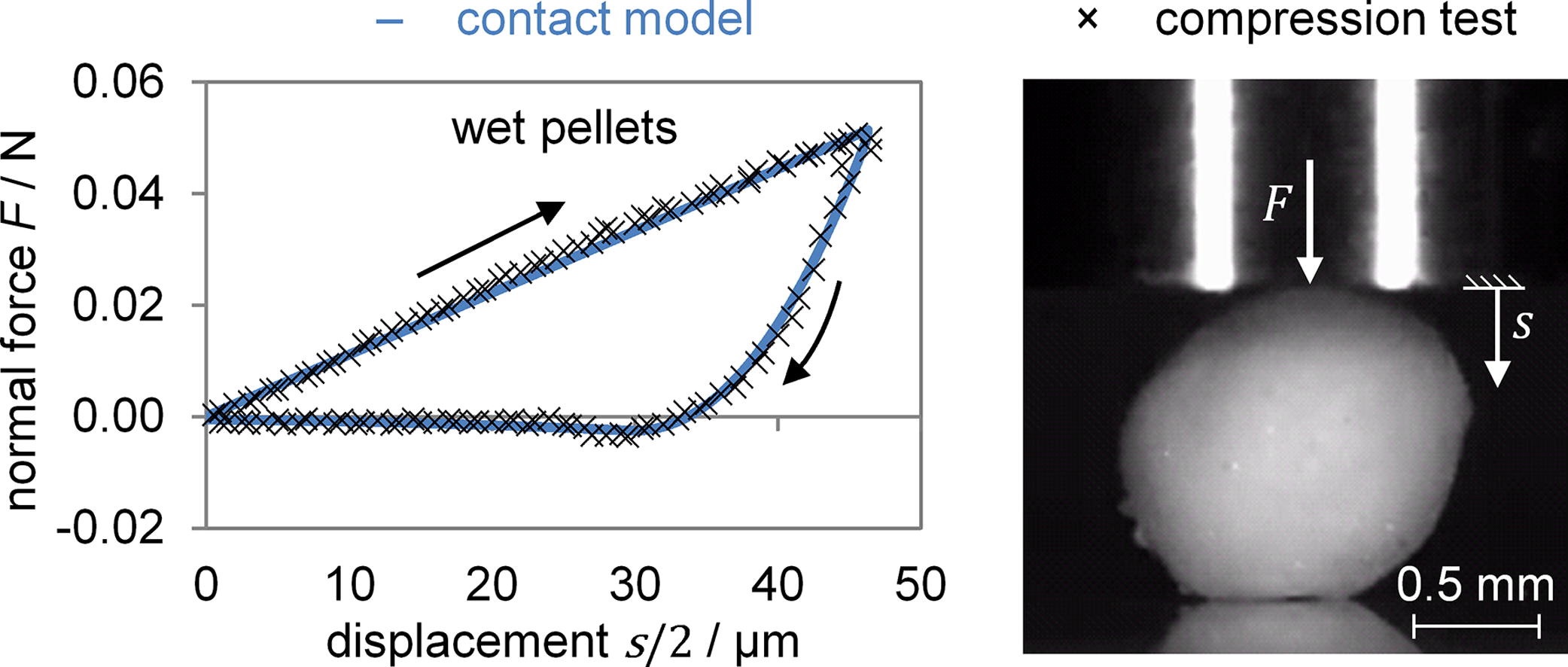

In order to model this rounding, a suitable contact model, which can predict the dominantly plastic deformation behaviour, is necessary. In this study, a novel cyclic model for wet and dry pellets was developed. Various single particle compression and impact tests with pellets produced from microcrystalline cellulose (MCC) and lactose were conducted to calibrate and validate this model.

It was found that the model is able to predict the energy dissipation as well as the deformation during pellet impact in the velocity range which is relevant for the spheronization process. Since the pellets are loaded multiple times during this process, the model was designed in order to account for the increasing flattening and hardening in the contact area as a function of the number of loading cycles.

Therefore, the presented model allows the description of the pellet deformation by repeated stressing. Access the article on pellet deformation