Batch vs. continuous direct compression – a comparison of material processability and final tablet quality

Abstract

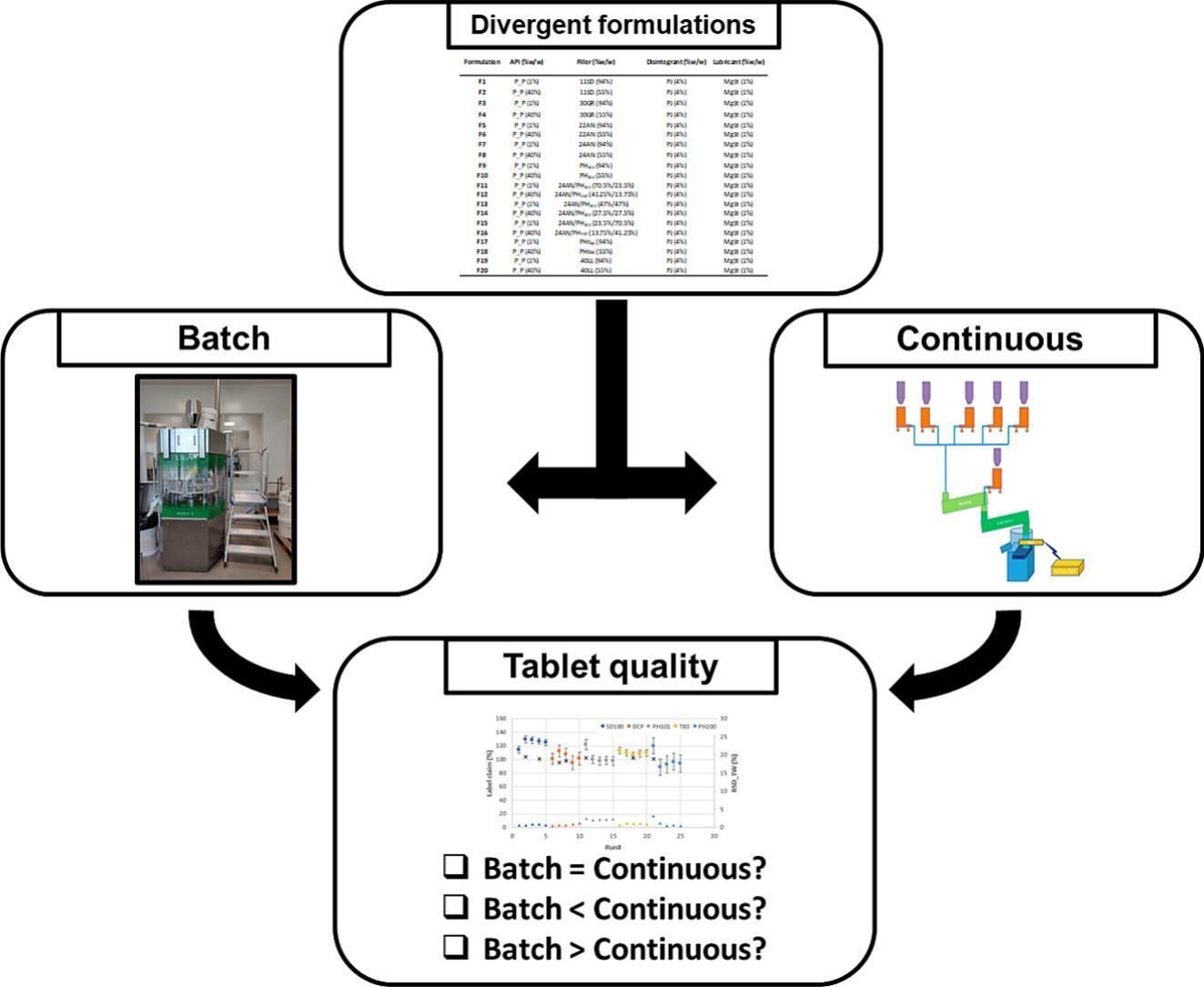

In this study, an in-depth comparison was made between batch and continuous direct compression using similar compression set-ups. The overall material processability and final tablet quality were compared and evaluated. Correlations between material properties, process parameters and final tablet properties were made via multivariate data analyses. In total, 10 low-dosed (1% w/w) and 10 high-dosed (40% w/w) formulations were processed, using a total of 10 different fillers/filler combinations. The trials indicated that the impact of filler type, drug load or process settings was similar for batch and continuous direct compression. The main differentiator between batch and continuous was the flow dynamics in the operating system, where properties related to flow, compressibility and permeability played a crucial role. The less consistent flow throughout a batch process resulted in a significantly higher variability within the tablet press (σCF) and for the tablet quality responses (σMass, σTS). However, the better controlled blending procedure prior to batch processing was reflected in a more consistent API concentration variability. Overall, the comparison showed the benefits of selecting appropriate excipients and process settings to achieve a specific outcome, keeping in mind some key differentiators between both processes.

Introduction

The pharmaceutical industry is more and more looking at continuous manufacturing as the way forward. The well-documented advantages of continuous processing (i.e. cost efficiency; better product quality, e.g. uniform blend and tablet content uniformity; efficient production; ease of scalability) that accompany continuous processing are the main driver for this switch (Schaber et al., 2011; Lee et al., 2015; Tezyk et al., 2015; Ierapetritou et al., 2016; Nasr et al., 2017). Furthermore, regulatory agencies have put effort into the development of a new guideline (ICH, 2023) which specifically focuses on continuous manufacturing of drug substances and drug products. It has recently been adopted by the European Medicines Agency (EMA), coming in full effect by July 2023.

The ‘simplicity’ of the process (i.e. only 3 unit operations required) of (continuous) direct compression ((C)DC) makes it one of the most used production techniques. This is evident from the wide variety of studies published on this topic, ranging from fully integrated CDC systems (Järvinen et al., 2013a; Järvinen et al., 2013b; Simonaho et al., 2016; Van Snick et al., 2017a; Van Snick et al., 2017b; García-Muñoz, 2017 Roth et al., 2017; Van Snick, 2019; Galbraith et al., 2019; Galbraith et al., 2020; Bekaert et al., 2022c) to more in-depth investigations of each unit operation: feeding (Engisch and Muzzio, 2014; Blackshields and Crean, 2018; Hanson, 2018; Bostijn et al., 2019; Sacher et al., 2020; Bekaert et al., 2021; Bekaert et al., 2022b); blending (Pernenkil and Cooney, 2006; Portillo et al., 2008; Gao et al., 2011; Osorio and Muzzio, 2016; Palmer et al., 2020; Bekaert et al., 2022a; Jaspers et al., 2021); and tableting (Patel et al., 2006; Sun, 2010; Peeters et al., 2018; Van Snick et al., 2018a; Galbraith et al., 2020; Ervasti et al., 2020; Dhondt et al., 2022).

Even though these studies demonstrated the benefits of continuous direct compression, direct comparisons between batch-wise and continuous processes are limited. Research evaluating the blending unit operation in function of raw material properties (APIs as well as fillers), reported several limitations of batch-wise powder blenders including scaling difficulties, less flexibility, poorer content uniformity and higher dependency on the material property (Roth et al., 2017; Oka et al., 2017; Jaspers et al., 2021; Jaspers et al., 2022). When tablet quality (i.e. content uniformity, tensile strength and tablet weight) was compared after manufacturing on an integrated batch line versus a CDC line, differences between batch and continuous were observed for both high-dosed and low-dosed formulations (Karttunen et al., 2019).

Despite the research that has been performed, there are still gaps remaining in the comparison between batch and continuous direct compression. To the best of our knowledge, the scope of most research is either limited to one specific unit operation (potentially disregarding specific interactions that could occur in a fully integrated line) or when a fully integrated line was compared – the use of different equipment (e.g. different tablet presses between batch and continuous) could hamper the data interpretation.

Table 1. Overview of selected materials, including the supplier information and abbreviations.

| Name | Material | Supplier | Code |

|---|---|---|---|

| SuperTab® 11SD | Spray dried lactose | DFE Pharma | 11SD |

| SuperTab® 30GR | Granulated lactose monohydrate | DFE Pharma | 30GR |

| SuperTab® 22AN | Anhydrous lactose | DFE Pharma | 22AN |

| SuperTab® 24AN | Granular anhydrous lactose | DFE Pharma | 24AN |

| SuperTab® 40LL | Co-processed lactose-lactitol | DFE Pharma | 40LL |

| Pharmacel® sMCC90 | Silicified microcrystalline cellulose | DFE Pharma | PHs90 |

| Pharmacel® 102 | Microcrystalline cellulose | DFE Pharma | PH102 |

| Primojel® | Sodium starch glycolate | DFE Pharma | PJ |

| Magnesium Stearate | Magnesium stearate | Sigma Aldrich | MgSt |

| Paracetamol Powder | Paracetamol powder | Mallinckrodt | P_P |

In order to fill these gaps, current study processed both low (i.e. 1%) and high-dosed (i.e. 40%) formulations in a batch-wise manner and compared the observations to CDC data generated during a previous study (Janssen et al., 2023). The acquired data sets were produced using a similar setup (i.e. similar tablet press configurations), allowing for a more accurate comparison between batch and continuous direct compression compared to previous research studies. In the end, the overall processability and final tablet quality were evaluated and linked via multivariate data-analysis (i.e. partial least squares regression). Focus of the analyses was put on batch versus continuous and how these processes differ when divergent formulations were processed.

Download the full article as PDF here: Batch vs. continuous direct compression – a comparison of material processability and final tablet quality

or read it here

B. Bekaert, P.H.M. Janssen, S. Fathollahi, D. Vanderroost, T. Roelofs, B.H.J. Dickhoff, C. Vervaet, V. Vanhoorne,

Batch vs. continuous direct compression – a comparison of material processability and final tablet quality,

International Journal of Pharmaceutics: X, Volume 7, 2024, 100226, ISSN 2590-1567, https://doi.org/10.1016/j.ijpx.2023.100226.