Cellactose® 80 – MEGGLE’s co-processed lactose grades for direct compression

MEGGLE is a pioneer in co-processing technologies that allow simple, robust formulation development and manufacture. Through co-processing, MEGGLE developed highly functional excipients possessing unique qualities for directly compressible immediate and sustained release pharmaceutical solid dosage forms.

Read the news of MEGGLE´s product Cellactose® 80 in the following article below and/ or download the technical brochure:

Cellactose® 80

General information

Direct compression (DC) tablet manufacture is a popular choice because it provides the least complex, most cost effective process to produce tablets compared to other tablet manufacturing approaches. Manufacturers can blend APIs with excipients and compress, making dosage forms simple to produce [1, 2].

DC technology and the use of modern tableting equipment require that excipients and APIs form a compactable mixture with excellent flowability and low particle segregation tendency [3].

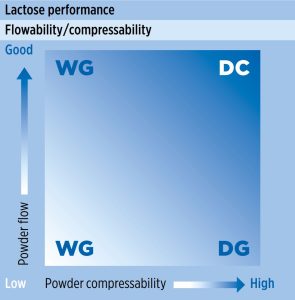

In the pharmaceutical industry, lactose is one of the most commonly used excipients; however, like many other excipients, lactose may not be suitable for direct compression without modification due to insufficient powder flow or/and compaction properties (figure 1).

Product description

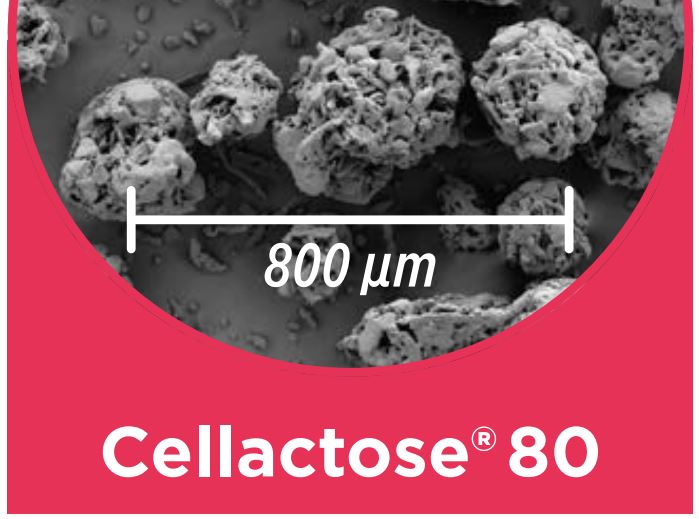

Alpha-lactose monohydrate and cellulose powder are functional excipients used in oral solid dosage forms. Both are naturally derived and well-established for use in the pharmaceutical industry. In an effort to create synergistic functional performance, such as improved compactability and mixing characteristics, co-spraydrying was used to integrate alpha-lactose monohydrate and cellulose powder into a monoparticulate system. Cellactose® 80 was developed to provide the flow and compaction properties necessary for direct compression tableting. Cellactose® 80 comprises 75 % alpha-lactose monohydrate and 25 % powdered cellulose, both maintaining their individual chemical identities.

Particle size distribution (PSD)

Figure 2 shows typical laser diffraction particle size distribution data for Cellactose® 80. Cellactose® 80 possesses a narrow PSD that is effective in preparing homogenous powder blends, a prerequisite in achieving good tablet quality.

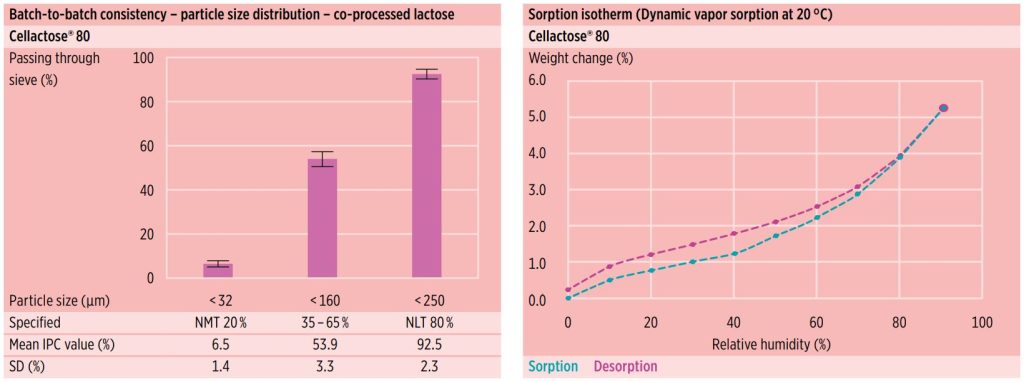

Figure 3 depicts the specified PSD range and typical average values by air-jet sieving. These parameters are constantly monitored through in-process control (IPC) testing and are part of the Cellactose® 80 particle size distribution specification.

Batch-to-batch consistency

Batch-to-batch consistency for all lactose products can be attributed to MEGGLE’s long history and experience in lactose manufacture, and broad technical expertise. Constant in-process and final product testing ensures consistency and quality (figure 4).

Isotherms

Cellactose® 80 exhibits moderate moisture uptake under high relative humidity conditions due to the cellulose powder influence on the observed equilibrium moisture content (figure 5)

See the full brochure on “Cellactose® 80” here

(click the picture to download the brochure)

Benefits Cellactose® 80

- Excellent compactibility and flowability

- Perfectly suited for poorly compressible APIs (e.g. herbal extracts)

- High adherence capacity to API

- Ideal tablet surface for easy and economical coating

- High adherence capacity may prevent segregation and improves content uniformity

Source: MEGGLE technical brochure “Cellactose® 80”

See the overview video of the MEGGLE Dry Powder Inhalation product range here:

Company: MEGGLE is one of the world´s leading manufacturers of pharmaceutical grade lactose and co-processed excipients with expertise of more than 70 years. We encounter lactose in so many areas of our life – reason enough to take a closer look at this multi-functional “white powder”.

Do you need more information or a sample of Cellactose® 80 excipients?