Material characterization with an extended Dwell Time compression profile on STYL’ONE NANO

During the development of a new drug, active materials are often available in small quantities for cost or process reasons. However, scientists have to understand their deformation behavior to design the best formulation possible and find suitable process parameters for production.

Compaction simulators, such as the STYL’One Nano, can easily explore compression dynamics and allow researchers to deeply understand their powder with only few grams of material. This premium technology is key for fundamental material characterization and deep understanding of your powder.

The goal of this bulletin is to dive into the Extended Dwell Time cycle available on STYL’One Nano and to demonstrate its usefulness in powder characterization with real practical examples.

Evaluate your powder viscoelasticity/viscoplasticity with an Extended Dwell Time compression profile

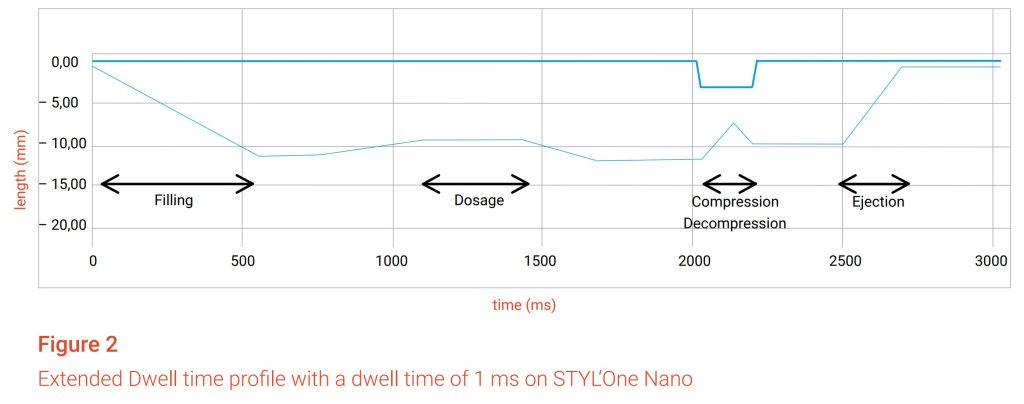

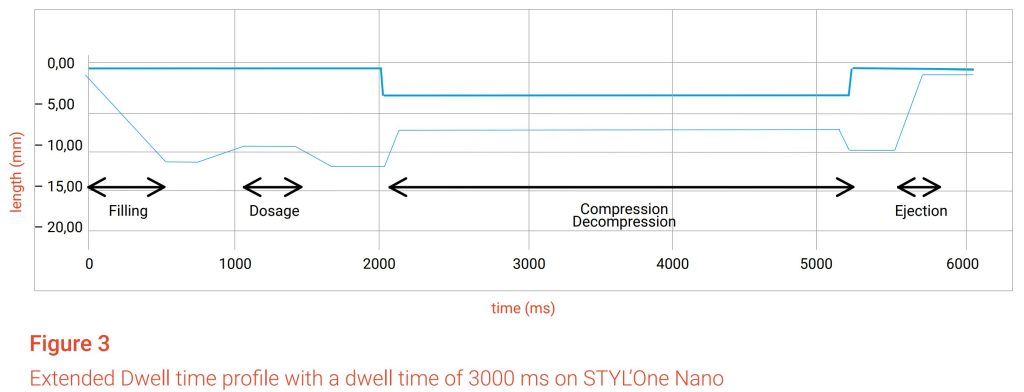

According to the Monograph 1062 of the US Pharmacopeia, the Extended Dwell Time profile is defined as “square punch displacement–time profile”.

According to the Monograph 1062 of the US Pharmacopeia, the Extended Dwell Time profile is defined as “square punch displacement–time profile”.

The dwell time is the period during which the punches are static throughout the compression cycle.

Having the capability to modify this dwell time in the range of 1 ms to 3 000 ms with the Extended Dwell Time profile will allow scientists to define the viscoelasticity/viscoplasticity behavior of their powders.

During compression, different deformation patterns can be observed: plastic, elastic, or brittle. Powder deformation can include a part of elastic, plastic, viscoplastic or viscoelastic deformation. Elastic deformation is a reversible deformation of particles in time function, whereas plastic deformation is irreversible and contributes to forming the tablet. Viscoplasticity or viscoelasticity means that the plastic or elastic deformation is time dependent. This can have a direct impact on tablets properties. At the contrary, brittle materials are not sensitive to speed.

See the full brochure “Material Characterization with an extended dwell time compression profile on STYL´ One NANO” here:

(click the picture to download the brochure)

Do you need some details or more information? Just fill in the contact form:

Source: MEDELPHARM brochure “Material Characterization with an extended dwell time compression profile on STYL´ One NANO”

STYL’One Nano key benefits:

The STYL’One Nano is compaction simulator focused on API characterization and formulation development. This R&D tablet press is invaluable during the first step of drug development. It allows researchers to:

- Understand API/excipient compression behavior (plastic, elastic, brittle, etc.)

- Offer improved performances (tableting properties, lubrication effect, etc.)

- Find optimal formulation to meet tablet quality attributes (hardness, dissolution, disintegration, friability, etc.) and cost target

- Explore process parameters (dry granulation, wet granulation, drying, milling, compression, etc.) and their impact on tablet quality attributes

- Save time and money during development