Investigating the heat sensitivity of frequently used excipients with varying particle sizes

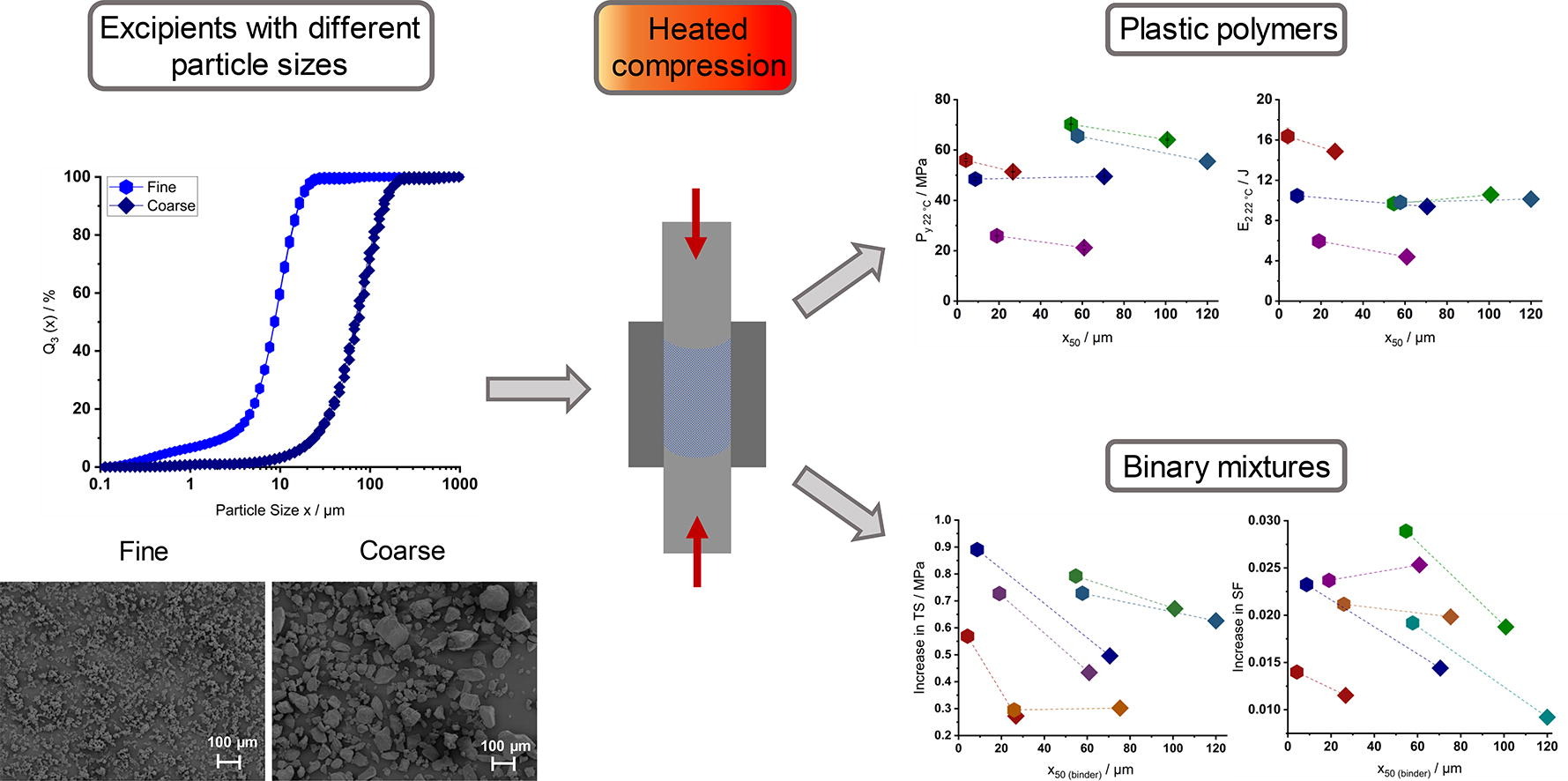

During tablet manufacturing an increase in the production temperature can lead to an alteration of tablet characteristics. In the present study, the influence of the initial particle size on the tableting behavior of ductile polymers upon temperature rise was investigated. Different grades of the respective materials were tableted at temperatures ranging from 22-70 °C.

Alterations in tableting behavior were affected by the initial particle size. Smaller particle sizes led to a more pronounced decrease in yield pressure and net work of compaction during compressibility analysis. The results were confirmed in the tabletability studies. Tablets from binary mixtures with lactose containing smaller polymer particles yielded a stronger increase in tensile strength. Differences in the tensile strength increase of two grades from the same material correlated with the ratio of their median particle sizes. The alteration of compactibility profiles was also particle size dependent. The increase in solid fraction was more prominent for binary mixtures containing polymers with smaller particle sizes. However, the ratio of the median particle sizes of the compared grades showed no systematic effect.

The results underline the importance of controlling the structural properties of a material carefully during formulation development and production. If a formulation responds to temperature variations, an increase in particle size might be beneficial to decrease its heat sensitivity.

Introduction

It is commonly acknowledged that the production temperature might rise drastically when tableting is performed on an industrial scale. However, its influence on the process itself and the resulting tablet properties is still not sufficiently understood.

Tablet manufacturing involves the partial conversion of mechanical to thermal energy. The mechanical energy input serves the particle rearrangement, elastic and plastic deformation as well as fragmentation [12], Zavaliangos, Galen et al. 2008). Several studies have explored the temperature evolution from tableting and its effect on tablet properties (Ketolainen, Ilkka et al. 1993, [33], Zavaliangos, Galen et al. 2008). A more detailed overview has recently been published (Grumann, Klinken et al. 2022).

Amongst the challenges during those investigations is the complexity of mechanical and structural properties when it comes to excipients and active pharmaceutical ingredients.

The particle size might influence a material’s deformation behavior. In general, pharmaceutical materials can be classified as either brittle, ductile or as a combination of both. Predominantly brittle materials are able to fragment during compression, which creates new areas for bonding. Plastic materials may create a large bonding area when the local stress exceeds their yield strength [41]. In that respect, one of the key properties to describe the tableting behavior of materials is the compressibility (Joiris, Di Martino et al. 1998, [42]. It describes the volume reduction of a powder under applied stress [44]. Frequently used methods for its assessment include Heckel analysis [14], [15]and the investigation of energy parameters (Higuchi, Arnold et al. 1952, [3], [9].

The influence of initial particle size on the compressibility is complex, since it is challenging to distinguish between contributing effects from particle size, shape, deformation and fragmentation behavior. Roberts and Rowe [36] postulated that the fracture stress decreases with increasing particle size, whereas plastic flow is independent of the particle size. Therefore, a material’s response to particle size variations might vary. If a material exhibits both brittle and ductile characteristics, the compressibility will initially decrease with decreasing particle size. At a critical particle size threshold, the fracture stress exceeds the yield stress of a material. The subsequent plastic flow is particle size independent [36]. This transition point can be referred to as the brittle-ductile transition [35].

In a study by McKenna and McCafferty [24], however, the material’s compaction mechanism was independent of its particle size. Heckel analysis was performed for two different dwell times to examine the predominant deformation mechanism for different size fractions of spray-dried lactose, microcrystalline cellulose and pregelatinized maize starch. The compaction mechanism was particle size independent for the investigated particle size ranges. Other authors found an increasing yield pressure with decreasing initial particle size for materials with different deformation behavior [48], [5], Garekani, Ford et al. 2001, Patel, Kaushal et al. 2007, [21], Wünsch, Finke et al. 2021, Ouazzou, Harshe et al. 2023). On the contrary, it has been stated that the yield strength increases with increasing particle size [40]. Sun and Grant [40] crystallized l-lysine monochloride and tableted various size fractions. However, it was concluded that the fragmentation of crystals might impede the interpretation of the results. A high amount of fragmentation might eliminate differences in particle size for brittle materials [37], [40], [43], Patel, Kaushal et al. 2007, [41]. These findings might explain why a generally valid description for the compressibility of a powder is still missing.

A powder’s compressibility might also affect its tabletability (tensile strength versus compression pressure) and compactibility (solid fraction versus tensile strength) [44]. The mechanical strength of a tablet can be described as an interplay between the bonding strength from different bonding mechanisms and the established bonding surface area (Leuenberger, Hiestand et al. 1981, Nyström, Alderborn et al. 1993, [29]. For a large bonding area, plastic flow of a material is key. It is also affected by other parameters like the particle size and shape [41]. The bonding strength is determined by the work of adhesion [19].

The positive effect of particle size reduction on tensile strength has been confirmed in a number of studies (Nyström, Mazur et al. 1982, [40], Kaerger, Edge et al. 2004, Liu, Marziano et al. 2013). However, it has also been stated that this is not true for all materials [24], [5].

The effect of temperature variations adds to the complexity of tableting behavior analyses for materials with different particle sizes. The sensitivity to heat of ductile polymers with a comparably low glass transition temperature (Tg) has been proven in several studies [34], [33], Partheniadis, Karantzalis et al. 2020, Grumann, Klinken et al. 2022, Grumann, Klinken et al. 2023). Beyond its Tg, a polymer softens and becomes more deformable [2]. In previous studies, the Tg of a material could directly be correlated to an alteration of process parameters (Grumann, Klinken et al. 2023) and tablet properties (Grumann, Klinken et al. 2022) for ductile polymers upon temperature rise. However, not all changes could be traced back to the Tg of the investigated excipients. Up to this point, no work has considered the particle size of materials when it comes to temperature variations. For the same material, smaller particles benefit from a larger specific surface area, which might promote their heat sensitivity.

The aim of this study was therefore to investigate the influence of the initial particle size on the temperature-dependent tableting behavior of ductile materials.

Materials

Except FlowLac® 100 (FL), all polymers have an amorphous or partially crystalline structure with plastic behavior. The heat sensitivity of all materials except Kollidon® CL (CL) and Kollidon® VA 64 (VA) has been proven in previous works (Grumann, Klinken et al. 2022, Grumann, Klinken et al. 2023). To investigate the influence of particle size, different grades from the same supplier were used if available to ensure comparable material properties

Read more

Hanna Dorothea Grumann, Peter Kleinebudde, Investigating the heat sensitivity of frequently used excipients with varying particle sizes, European Journal of Pharmaceutics and Biopharmaceutics, 2023, ISSN 0939-6411,

https://doi.org/10.1016/j.ejpb.2023.09.010.