Assessment of Tribo-charging and Continuous Feeding Performance of Direct Compression Grades of Isomalt and Mannitol Powders

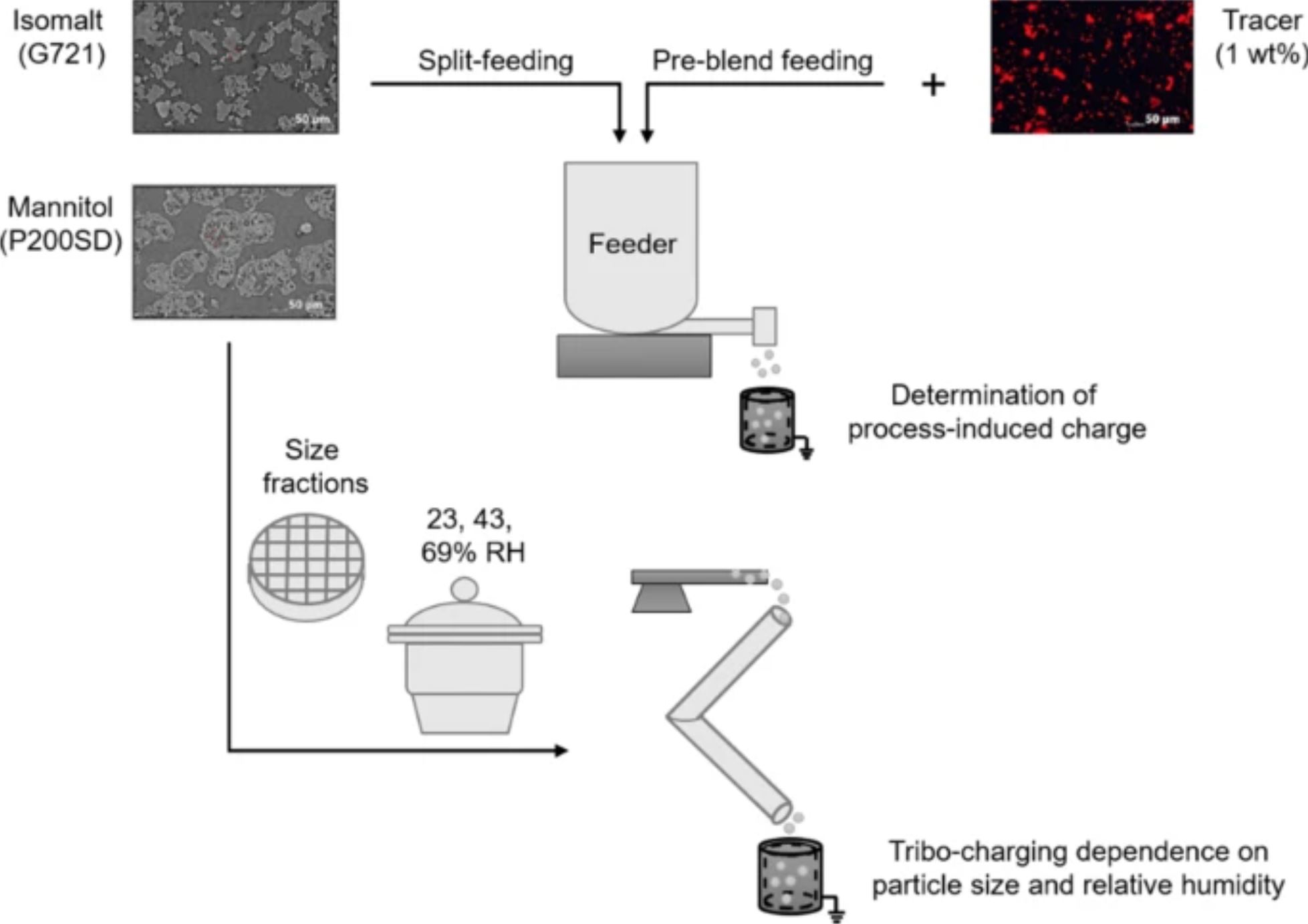

Tribo-charging is often a root cause of mass flow deviations and powder adhesion during continuous feeding. Thus, it may critically impact product quality. In this study, we characterized the volumetric (split- and pre-blend) feeding behavior and process-induced charge of two direct compression grades of polyols, galenIQ™ 721 (G721) for isomalt and PEARLITOL® 200SD (P200SD) for mannitol, under different processing conditions. The feeding mass flow range and variability, hopper end fill level, and powder adhesion were profiled. The feeding-induced tribo-charging was measured using a Faraday cup. Both materials were comprehensively characterized for relevant powder properties, and their tribo-charging was investigated for its dependence on particle size and relative humidity. During split-feeding experiments, G721 showed a comparable feeding performance to P200SD with lower tribo-charging and adhesion to the screw outlet of the feeder.

Depending on the processing condition, the charge density of G721 ranged from -0.01 up to -0.39 nC/g, and for P200SD from -3.19 up to -5.99 nC/g. Rather than differences in the particle size distribution of the two materials, their distinct surface and structural characteristics were found as the main factors affecting their tribo-charging. The good feeding performance of both polyol grades was also maintained during pre-blend feeding, where reduced tribo-charging and adhesion propensity was observed for P200SD (decreasing from -5.27 to -0.17 nC/g under the same feeding settings). Here, it is proposed that the mitigation of tribo-charging occurs due to a particle size-driven mechanism.

Download the full article as PDF here Assessment of Tribo-charging and Continuous Feeding Performance of Direct Compression Grades of Isomalt and Mannitol Powders

or read it here

Materials

The agglomerated isomalt galenIQ™ 721 (G721, BENEO-Palatinit GmbH, Germany) and the spray-dried mannitol grade PEARLITOL® 200SD (P200SD, Roquette, France) were investigated in the present study. G721 is a disaccharide alcohol consisting of a 6-O-α-D-glucopyranosyl-D-sorbitol/1-O-α-D-glucopyranosyl-D-mannitol dihydrate (GPS/GPM) ratio of 3:1 [3]. P200SD is a mixture of α- and β-mannitol polymorphs [29]. For the preparation of the respective binary blends, an E124 colored food dye (tracer, Wurth Essenzenfabrik GmbH, Austria) was sieved below 45 µm to resemble a model API.

Beretta, M., Kruisz, J., Hörmann-Kincses, T.R. et al. Assessment of Tribo-charging and Continuous Feeding Performance of Direct Compression Grades of Isomalt and Mannitol Powders. AAPS PharmSciTech 24, 91 (2023). https://doi.org/10.1208/s12249-023-02552-5