An update on microcrystalline cellulose in direct compression: Functionality, critical material attributes, and co-processed excipients

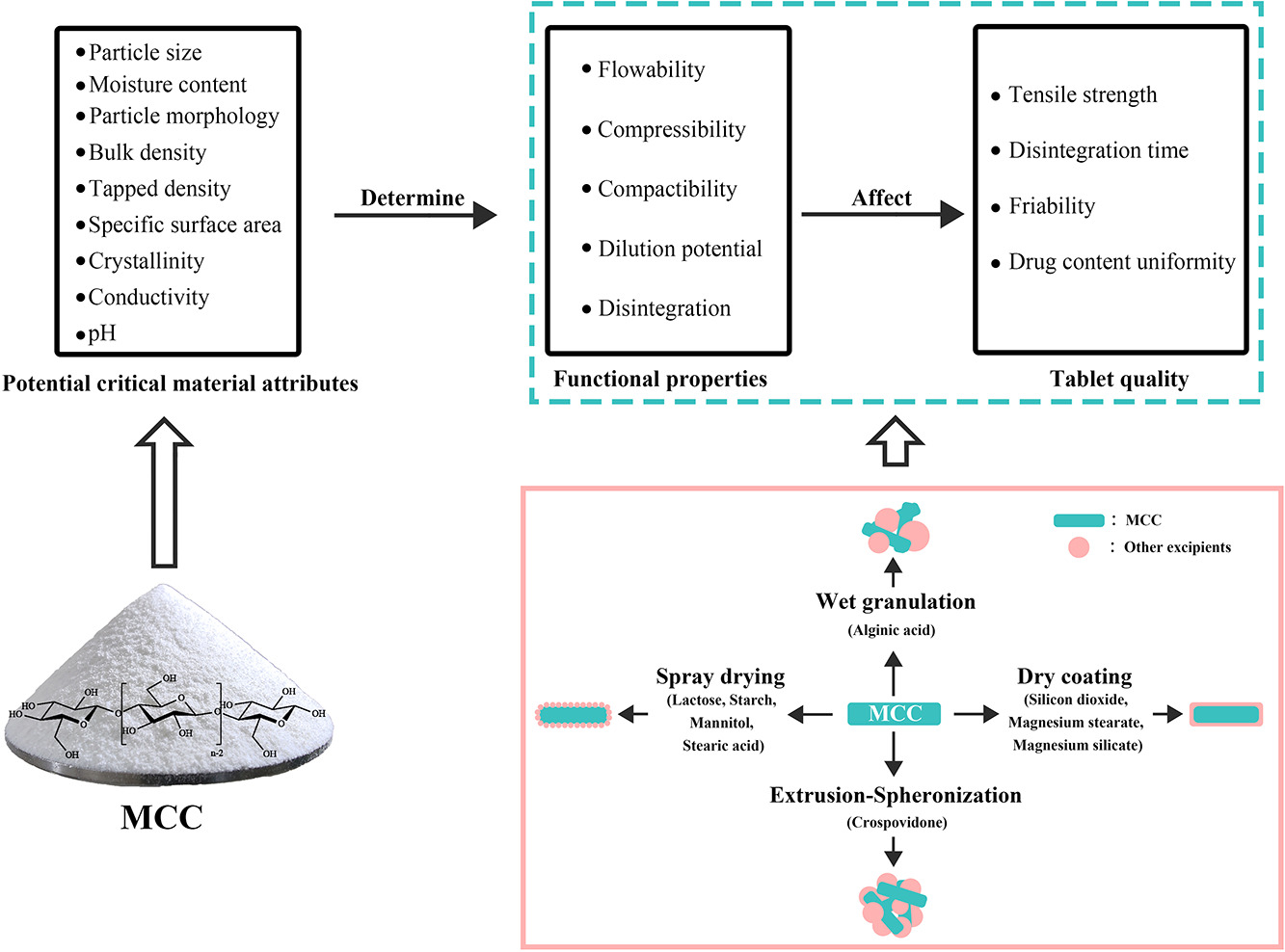

Microcrystalline cellulose (MCC) is one of the most popular cellulose derivatives in the pharmaceutical industry. Thanks to its outstanding tabletability, MCC is generally included in direct compression (DC) tablet formulations containing poor-tabletability active pharmaceutical ingredients. Nowadays, numerous grades of MCC from various brands are accessible for pharmaceutical manufacturers, leading to variability in MCC properties.

See an overview of MCC grades in our shop

Hence, it seems to be worthy and urgent to evaluate the influences of MCC variability on tablet quality and to identify critical material attributes (CMAs) based on the idea of Quality by Control. Besides, MCC-based co-processed excipients can effectively combine the functions of the filler, binder, disintegrant, lubricant, glidant, or flavor, and thus have drawn extensive interest.

In this review, we focused specifically on the recent advances and development of MCC on DC tableting, including the functions in tablet formulations, potential CMAs, and MCC-based co-possessed excipients, therefore providing a reference for further studies.

Article information: Haiyue Zhao, Lijie Zhao, Xiao Lin, Lan Shen, An update on microcrystalline cellulose in direct compression: Functionality, critical material attributes, and co-processed excipients, Carbohydrate Polymers, 2021. https://doi.org/10.1016/j.carbpol.2021.118968.

See also our basics article on the use of Microcrystalline Cellulose in the pharmaceutical industry