A strategy to optimize precompression pressure for tablet manufacturing based on in-die elastic recovery

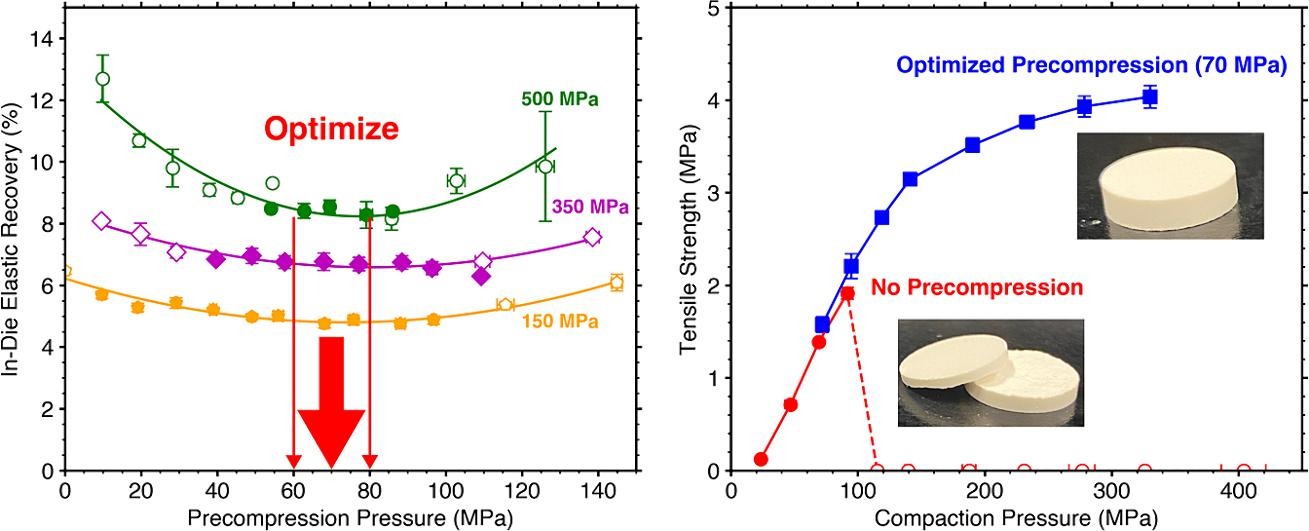

A precompression pressure optimization strategy using in-die elastic recovery was developed to effectively address tablet lamination caused by air entrapment. This strategy involves exacerbating the air entrapment issue using high tableting speeds and main compaction pressures and collecting in-die elastic recovery data as a function of precompression pressure. The optimized precompression pressure, which corresponds to the minimum elastic recovery, is most effective at eliminating air from the powder bed prior to the main compression.

When the optimized precompression pressure was employed, intact tablets of a model blend prone to lamination due to air entrapment could be produced over a wide range of high main compaction pressures, while tablets without precompression laminated immediately after ejection at equivalent main compaction pressures. This optimization strategy is effective for addressing lamination issues due to air entrapment using precompression. An advantage of this strategy is that intact tablets are not required to identify an optimized precompression pressure since elastic recovery measurements occur in-die.

Read more here

Materials

Microcrystalline cellulose (MCC; Avicel® PH102, International Flavors & Fragrances, Philadelphia, PA) and magnesium stearate (MgSt; non-bovine, HyQual™, Mallinckrodt, St. Louis, MO) were used as received.

Gerrit Vreeman, Changquan Calvin Sun, A strategy to optimize precompression pressure for tablet manufacturing based on in-die elastic recovery, International Journal of Pharmaceutics, Volume 654, 2024, 123981, ISSN 0378-5173,

https://doi.org/10.1016/j.ijpharm.2024.123981.

Read also our introduction article on Magnesium Stearate here: