In-line particle size measurement during granule fluidization using convolutional neural network-aided process imaging

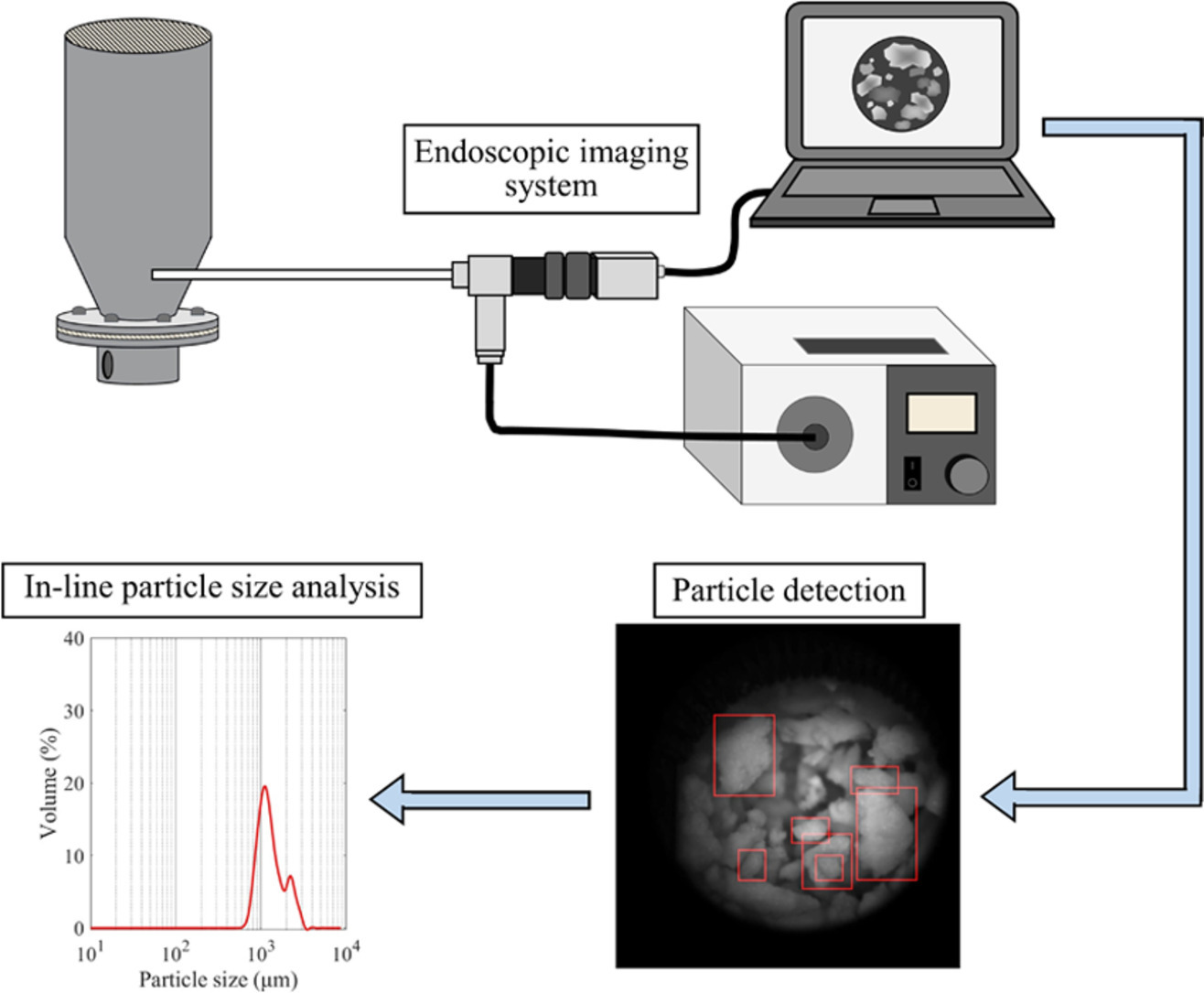

This paper presents a machine learning-based image analysis method to monitor the particle size distribution of fluidized granules. The key components of the direct imaging system are a rigid fiber-optic endoscope, a light source and a high-speed camera, which allow for real-time monitoring of the granules.

Highlights

An endoscopy-based direct imaging system can monitor granules during fluidization.

A convolutional neural network-based software was applied for particle detection.

In-line particle size measurement was accomplished despite dense particle flow.

The in-line measurements and off-line reference methods showed similar trends.

The system was implemented into a custom-made 3D-printed device that could reproduce the particle movement characteristic in a fluidized-bed granulator. The suitability of the method was evaluated by determining the particle size distribution (PSD) of various granule mixtures within the 100–2000 μm size range. The convolutional neural network-based software was able to successfully detect the granules that were in focus despite the dense flow of the particles. The volumetric PSDs were compared with off-line reference measurements obtained by dynamic image analysis and laser diffraction. Similar trends were observed across the PSDs acquired with all three methods. The results of this study demonstrate the feasibility of performing real‐time particle size analysis using machine vision as an in-line process analytical technology (PAT) tool.

2.1. Materials

Dextrose granules were prepared with α-D glucose monohydrate (Hungrana, Hungary). Distilled water was used as granulation liquid. Starch-lactose granules contained polyvinylpyrrolidone (Kollidon® 30, PVPK30, BASF, Ludwigshafen, Germany) as binder, which was dissolved in 96% ethanol (Sigma-Aldrich, Budapest, Hungary). Potato starch (Roquette Pharma, Lestrem, France) and α-lactose monohydrate (GranuLac® 230 mesh, Meggle Pharma, Wasserburg, Germany) were used as the solid excipients.

Download the full study as PDF here: In-line particle size measurement during granule fluidization using convolutional neural network-aided process imaging

or read it here

Orsolya Péterfi, Lajos Madarász, Máté Ficzere, Katalin Lestyán-Goda, Petra Záhonyi, Gábor Erdei, Emese Sipos, Zsombor Kristóf Nagy, Dorián László Galata, In-line particle size measurement during granule fluidization using convolutional neural network-aided process imaging, European Journal of Pharmaceutical Sciences, Volume 189, 2023, 106563, ISSN 0928-0987,

https://doi.org/10.1016/j.ejps.2023.106563.