Colon Drug Delivery Systems Based on Swellable and Microbially Degradable High-Methoxyl Pectin: Coating Process and In Vitro Performance

Abstract

Introduction

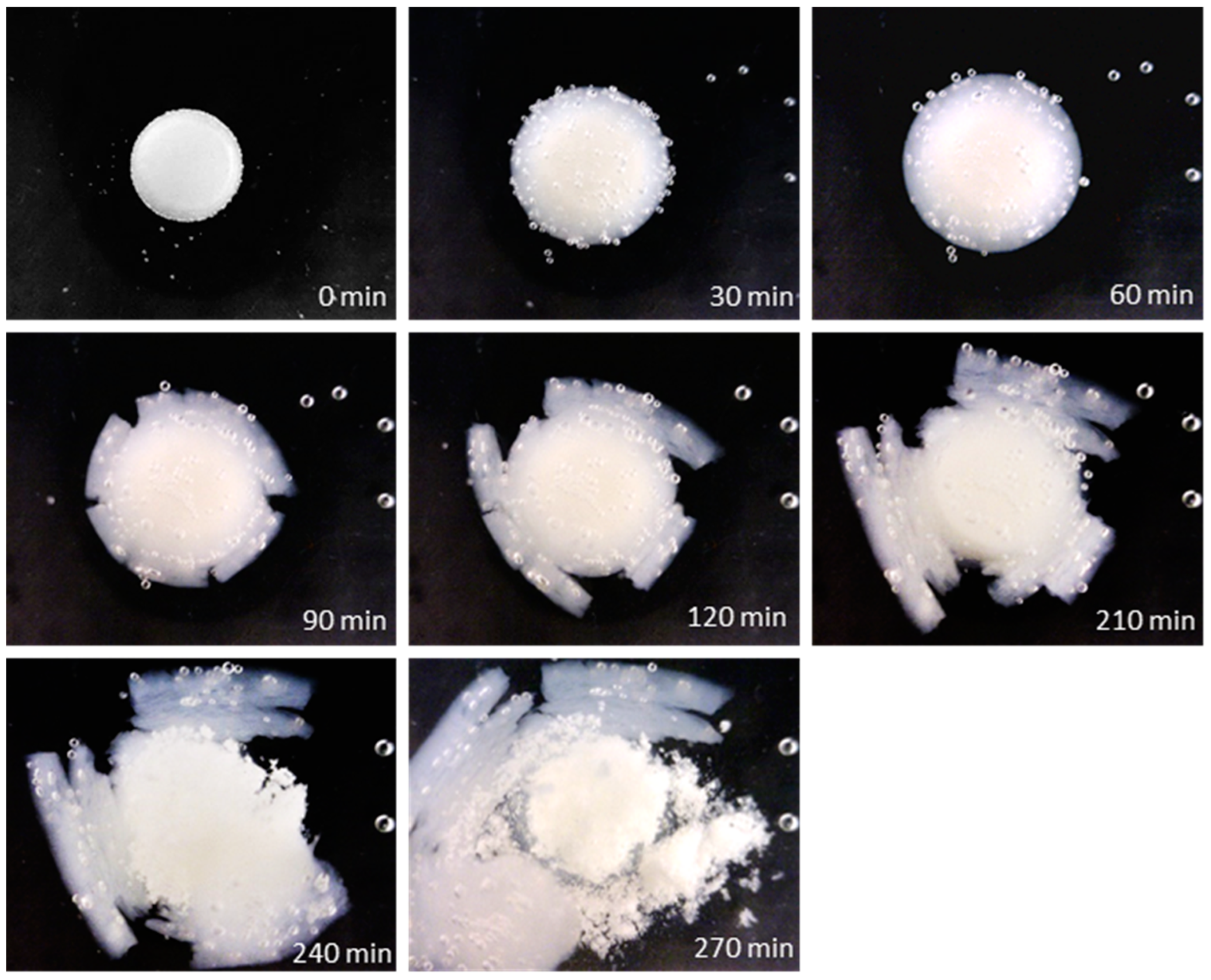

Oral colon delivery has been extensively investigated to effectively treat intestinal disorders, such as primarily inflammatory bowel disease (IBD), and to replenish the microbiota [1,2,3,4,5]. Furthermore, it is of interest for the administration of biotechnological drugs, namely peptides, proteins, oligonucleotides and nucleic acids, which may face less harsh conditions in the distal gut as compared with the stomach and small intestine due to lower concentrations of digestive enzymes and physiological surfactants [6,7,8,9]. For colon delivery purposes, numerous polysaccharides of natural origin have been exploited [10,11]. These have primarily been incorporated into insoluble or enteric-soluble coatings to trigger release from the core through bacterial degradation once the coated dosage form has entered the large bowel [12,13,14,15,16,17,18,19,20]. Also, they have been used as such to act as matrix-forming or coating agents susceptible to enzymatic breakdown [21,22,23]. Interestingly, such coatings may combine the ability to swell/dissolve/erode upon exposure to aqueous fluids, thus deferring the onset of drug release in the upper gastrointestinal tract, with selective microbial degradability in the colon. The effect of biodegradation would become even more important in case a high amount of polysaccharide has to be applied to prevent possible premature release in the small bowel. This represents a possible advantage over non-biodegradable swellable/erodible polysaccharides used so far according to the time-dependent colon delivery strategy, which may form a persistent swollen polymer layer hindering timely and complete release at the target site [2,24,25]. Such issues have been addressed by incorporating cellulolytic enzymes into a previously described reservoir colon delivery system, either within its hydroxypropyl methylcellulose (HPMC) layer or as an underlying film, with the aim to promote erosion of the functional coating in the colonic region [26].

Among the various polysaccharides used for microbially-triggered colonic release, pectin, a D-galacturonic acid-rich hetero-polysaccharide found in plant cell walls, plays a prominent role [27]. Indeed, it has broadly been used as a colon-targeting excipient, mostly combined with insoluble polymers in an attempt to mitigate the impact of the relevant hydrophilicity and water solubility characteristics and attain a durable barrier [28,29,30,31]. To this end, high-methoxyl pectin has been chosen. Indeed, a higher methoxylation degree reduces solubility and promotes gelation because of lower repulsion forces between free adjacent carboxyl groups [32,33].

Pectin coatings have mainly been applied by press-coating, and only a few attempts to use it as a spray-coating agent have been reported [34,35,36,37,38,39,40]. Nevertheless, press-coating technique is known to involve inherent technical limitations. Particularly, achieving a homogeneous coating thickness has proved challenging, and poor flexibility in the coating level is allowed. In addition, polysaccharides of natural origin may not exhibit acceptable compaction properties [37,41]. Indeed, non-coherent pectin compacts have been described, resulting in powder loss, impaired coating functionality and lack of a consistent release performance.

On the other hand, the main technical hurdles encountered with spray-coating technique are associated with the relatively high viscosity of the aqueous solutions of most natural polysaccharides of interest for colon delivery purposes. This leads to nebulization issues (sprayability), making the use of highly diluted coating formulations and long process times necessary to reach the desired thickness of the applied layer. To overcome such drawbacks, hydro-alcoholic media have been employed, limiting the extent of hydration of the polysaccharides [21,22,42,43]. However, organic solvents are not currently recommended due to safety concerns.

Recently, powder-layering technique has been proposed for the application of time-dependent functional coatings based on HPMC [5,44]. This technique, which has been developed for loading active pharmaceutical ingredients in powder form onto inert cores, consists in the addition of powders and of a binding formulation in alternating or simultaneous mode inside the process chamber of the coating equipment, where the substrates are properly fluidized [45]. The powders adhere to the wet cores, and, due to liquid inter-particle bonds turning into solid structures after solvent evaporation, ultimately form a coherent layer. For HPMC application, the powder-layering process was carried out by a fluid bed apparatus equipped with a tangential-spray insert and compared with aqueous spray-coating using the same equipment in top- and tangential-spray configurations [44]. With powder-layering, the process time was considerably reduced, and the yield was also improved, albeit to a lesser extent. Moreover, such coatings were found to defer the in vitro release as desired, and the relevant performance was comparable or even more efficient than that of spray-coated systems. Based on these results, powder-layering would offer an interesting potential for circumventing major shortcomings of polysaccharide coatings, thus possibly sparking new interest in polymers previously discarded due to processing issues.

Hence, the present work aimed to investigate hydrophilic and microbially degradable high-methoxyl (HM) pectin layers for colon delivery applied either by powder-layering or spray-coating. The coating formulations and process parameters were set up, and physico-technological characteristics as well as in vitro release performance of the coated systems were studied, with a special focus on the relationship between coating technique, structure of the applied layer and relevant efficiency in imparting a lag phase prior to release.

Download the full article as PDF here: Colon Drug Delivery Systems Based on Swellable and Microbially Degradable High-Methoxyl Pectin

or read it here

Materials

Paracetamol for direct compression (RhodapapTM DC 90, Novacyl, Lyon, France) was used as an analytical tracer to study the release performance of the designed formulations. The tablet formulation also included microcrystalline cellulose (Avicel® PH-101, FMC Co., San Colombano al Lambro, Italy), sodium starch glycolate (Explotab® CLV, JRS Pharma, Castenedolo, Italy), vinylpyrrolidone–vinyl acetate copolymer (Kollidon® VA 64, BASF Italia Spa, Cesano Maderno, Italy), hydrophilic fumed silica (Aerosil® 200, Evonik Degussa Italia Spa, Pandino, Italy) and magnesium stearate (Recordati Spa, Milan, Italy). For the coating formulations, high-methoxyl pectin, d10 37.8 µm, d50 135.0 µm, d90 273.0 µm (HM pectin, Aglupectin® HS-RP, JRS Silvateam Ingredients Srl, Bergamo, Italy), hydroxypropyl methylcellulose (HPMC, MethocelTM E5 and MethocelTM K100LV, Colorcon, Dartford, UK), glycerol (ACEF Spa, Fiorenzuola d’Arda, Italy), glycerol monostearate (GMS, Gattefossè SAS, Saint-Priest, France), polysorbate 80 (Tween® 80, ACEF Spa), methacrylic acid and ethylacrylate copolymer (1:1), 30% w/w aqueous suspension (Kollicoat® MAE 30DP, BASF Italia Spa), talc (ACEF Spa) and propylene glycol (PG; ACEF Spa) were employed.

Moutaharrik, S.; Palugan, L.; Cerea, M.; Meroni, G.; Casagni, E.; Roda, G.; Martino, P.A.; Gazzaniga, A.; Maroni, A.; Foppoli, A. Colon Drug Delivery Systems Based on Swellable and Microbially Degradable High-Methoxyl Pectin: Coating Process and In Vitro Performance. Pharmaceutics 2024, 16, 508. https://doi.org/10.3390/pharmaceutics16040508

See our next webinar:

“Rethinking the development of controlled release formulations and manufacturing processes”

Date: 30th of April, Time: 3:00 pm (Amsterdam, Berlin)