Tableting of liquid form active ingredient with high performance liquid carrier

1. Introduction

Many liquid active ingredients are supplied in a soft-gel capsule form, because a soft gel capsule is easy to release control and can avoid formulation difficulties. However, it has serious weakness in stability, especially in humid environments; swallowability in the elder people, and formative compatibility with other ingredients. Several inactive ingredients have been provided as liquid carriers to liquid-solid formulation, however they don’t retain much liquid stably or meet tableting performance as expected.

Tomita’s FLORITE is a macro porous calcium silicate with considerable liquid absorbency and compressibility, and it is able to offer practical powderization capability to tableting formulation with liquid active ingredients.

2. Liquid powderization

For the model material of active liquid ingredients – fish oil was selected due to its unstable characteristics and it is well-known as soft-gel form products.

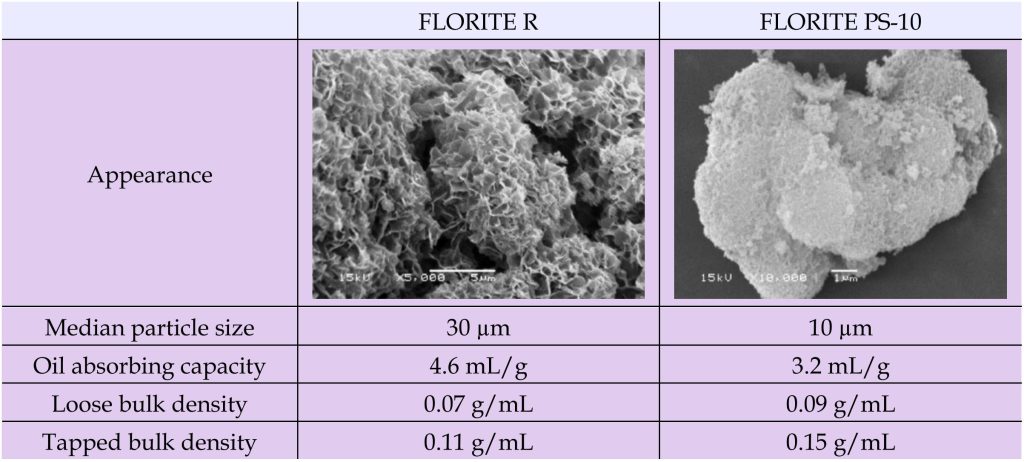

FLORITE R and PS-10 were applied to tuna fish oil absorption under various mixing ratio conditions, and silicon dioxide was chosen as a reference material. Liquid was absorbed in a closed mixing machine. FLORITE is synthetic calcium silicate which has a petaloid structure with developed deep and large macro pores on the particle. Such pores are applicable to liquid carrying, binding, stabilizing and solid dispersion. FLORITE R is a standard product of the FLORITE brand, and it is a light powder with high liquid absorbency. FLORITE PS-10 is a fine powder type, and it has enough liquid absorbency.

Table 1 Characteristics of FLORITE

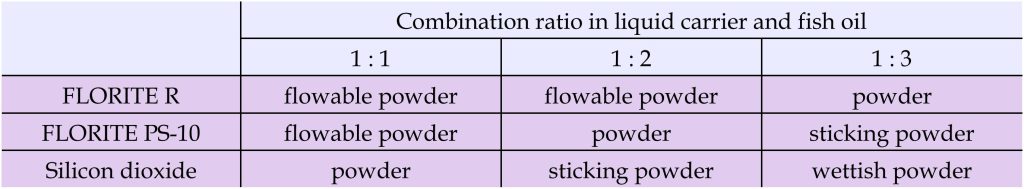

All FLORITE products can make fish oil powder up to the combination of 1 to 2 but silicon dioxide didn’t make it except with 1 to 1.

Table 2 Properties of fish oil powder

3. Stability study

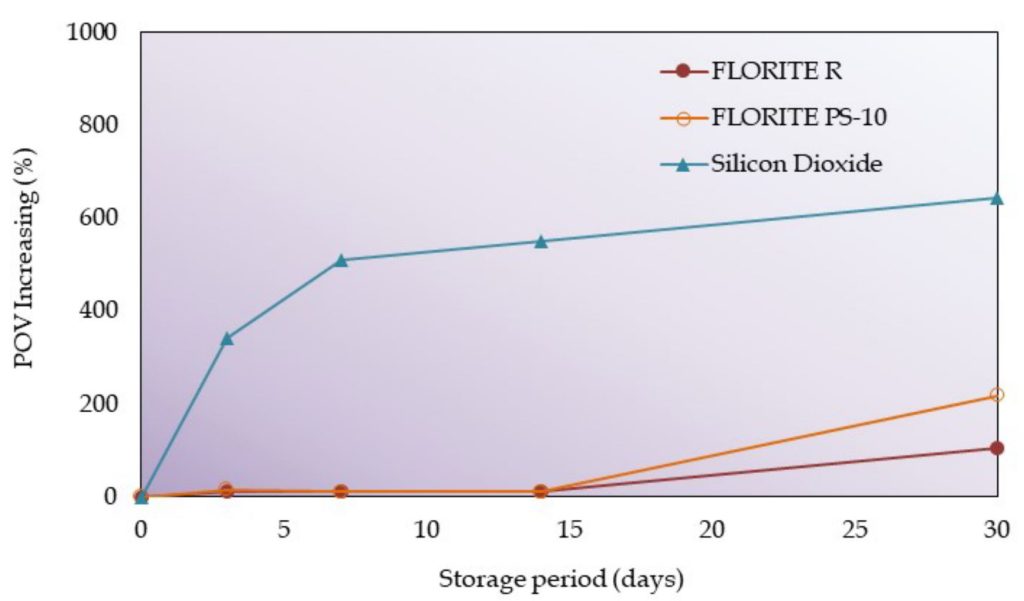

Fish oil carrying powder with each material in the loading ratio of 1 to 1, was used in a stability study and it was in a closed container in the chamber maintaining 104˚F(40˚C).

The stability of fish oil was determined with peroxide value (POV) analysis because it is a simple way of detecting oxidation status. FLORITE R and PS-10 suppressed the POV rising of fish oil for a long period. However, silicon dioxide couldn’t prevent the oxidation of fish oil. Fish oil was retained in the deep macro pores of FLORITE, far from the outside air. The silicon dioxide does not have such deep pores, therefore it is difficult to let fish oil star away from air.

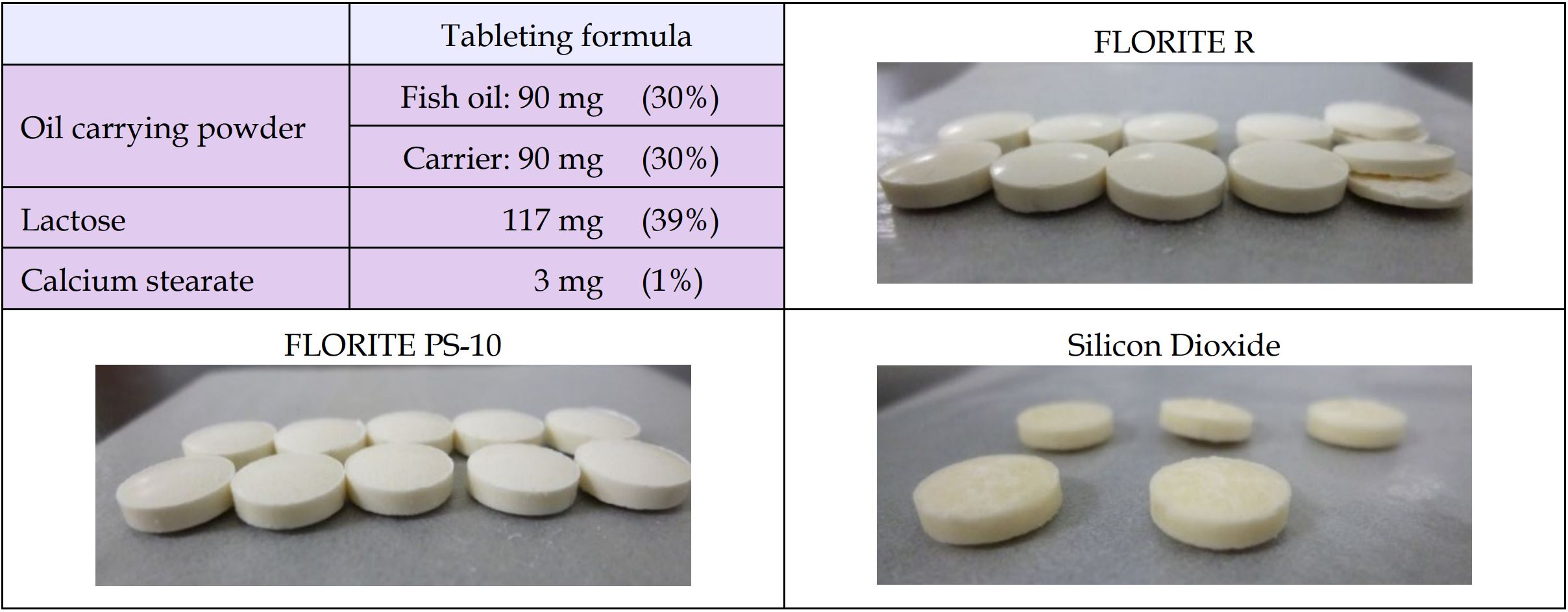

4. Liquid-Solid tableting

We compressed the mixture powder which contains 30% fish oil ,30% liquid career, and 40% lactose and calcium stearate as excipients using a single-punch tableting machine in the condition with 10 kN/10 mm dia. Almost all FLORITE R tablets had sufficient hardness and cleanness, sometimes occurring as a lamination defect. All FLORITE PS-10 tablets had superior hardness and cleanness without any tableting defects. In the case of silicon dioxide, it didn’t achieve practical tablet and tabletability.

See the full technical brochure on “Tableting of liquid form active ingredient with high performance liquid carrier” here

(click the picture to download the brochure)

Source: Tomita technical brochure “Tableting of liquid form active ingredient with high performance liquid carrier”

Interested in more information or a sample? Just fill in the contact form:

Meet Tomita on following events:

- Supply Side West /23-27 October 2023 /Booth No:3886

- AAPS PHARMSCI360 /22-26 October 2023 /Booth No:3327